Installation, 5 appliance location, 6 appliance installation – Glow-worm Clearly Hybrid - Compact Hydraulic Module HB User Manual

Page 7

0020096881_02 - 08/10 - Glow-worm

- 5 -

INSTALLATION

INSTALLATION

5 Appliance location

• Before choosing a site for the appliance, carefully read the

safety warnings and installation manual.

• Ensure that wall to which the appliance will be mounted on is

structurally safe in order to support the weight of the appliance.

• Ensure there is sufficient space available for the appliance,

taking care that minimum clearances are adhered to ensure

that the connections to the water can be accessed and

inspected.

• The appliance must be installed in a room protected from

freezing. Take all necessary precautions.

• Explain these requirements to the appliance user.

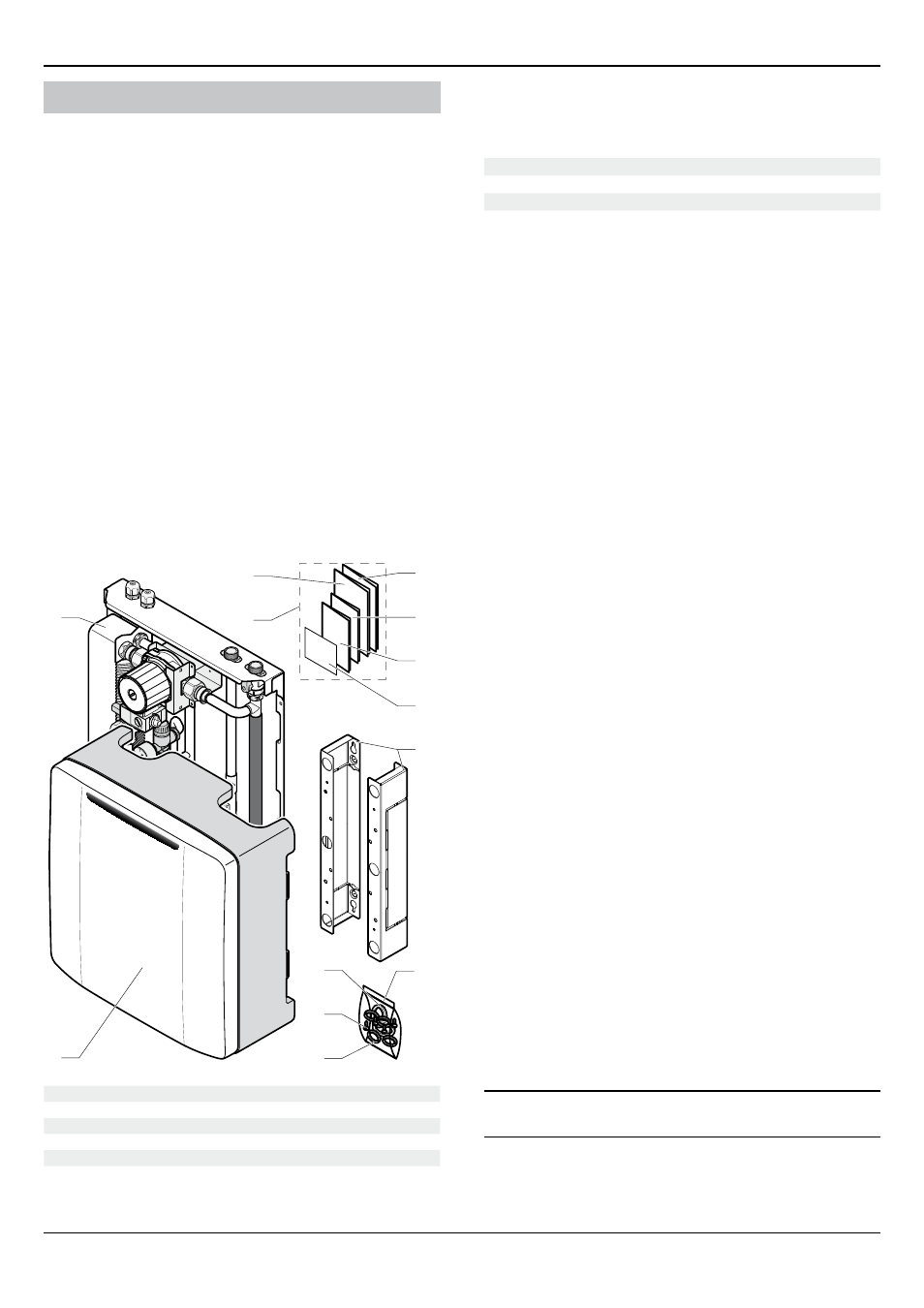

6 Appliance installation

6.1

Scope of delivery

2

3.1

3

1

5.1

5.2

5.3

4

3.2

5

3.3

3.4

3.5

Key

1

Hydraulic module cover

(x1)

2

Hydraulic module

(x1)

3

Documents bag

(x1)

3.1

System installation manual

(x1)

3.2

Module installation manual

(x1)

3.3

Module instructions for use

(x1)

3.4

Guarantee conditions

(x1)

3.5

Guarantee card

(x1)

4

frame

(x2)

5

Accessories bag

(x1)

5.1

flat seal ¾"

(x6)

5.2

frame screws

(x4)

5.3

flat seal 1 "

(x4)

• Check the contents of the packages.

6.2

Recommendations before installing

6.2.1

Heating circuit design

The heat transmitters may be low temperature (under-floor

heating, low-temp radiator ...) and high temperature (cast iron

radiator ...).

The installation pipework should be calculated using a flow /

pressure curve. The distribution will be determined by the flow

corresponding to the power actually required, regardless of

the maximum power that can be provided by the installation’s

generators.

The pipework should be designed and installed in such a way

so as to make all provisions necessary to avoid air pockets and

facilitate the permanent degassing of the installation. Venting

valves must be placed at each high point of the tubes, as well as

on all radiators.

The total volume of water for the heating circuit depends,

among other factors, on the cold static load of the boiler’s

expansion tank. It is recommended that a drainage valve be

installed at the lowest point of the installation.

If using thermostatic valves, do not equip all radiators with

them, placing these valves at high demand sites and never at

the sites in which the room thermostats are installed.

- In both new and existing installations, the radiator circuit

must be flushed prior to installing the new appliance in

accordance with BS:7593.

- If a system component is not put in place immediately,

protect the different connections so that the plaster and paint

does not spoil water tightness for later connecting.

6.2.2

Heat pump circuit design

The pipework should be designed and installed in such a way

so as to make all provisions necessary to avoid air pockets and

facilitate the venting of air from the installation. Bleed valves are

to be installed at each of the pipes' highest points.

• In order to avoid the transmission of vibration to surrounding

structures, use hoses for water connections.

b

Insulate the pipes with a UV- and high-

temperature-resistant insulation.