Maintenance, 6maintenance – Glow-worm Clearly Heat Pumps Envirosorb3 User Manual

Page 18

0020154078_00 - 02/13 - Glow-worm

18

MAINTENANCE

5.4.2

Adjusting the hydraulic circuit fl ow rate

The heat pump is designed to operate above a minimum fl ow

rate. If the heat pump functions at a minimum fl ow rate, this

will result in a loss of power and performance. The heating

comfort will still be guaranteed but the energy savings will be

reduced.

Envirosorb3 8

Envirosorb3 11

Minimum fl ow

380 l/h

540 l/h

Recommended fl ow

1400 l/h

1900 l/h

It is possible to read the fl ow rate directly on the controller.

Depending on the type of fl uid used in the hydraulic circuit,

the fl ow rate displayed on the control box may be over-

estimated.

Example: If you use a 30% propylene glycol mixture and the

fl uid temperature is 5°C, you must subtract 400l/h from the

value displayed on the control box.

∙ Refer to the table below for the various values of over-

estimation of the fl ow rate depending on the fl uid type and

temperature.

Flow rate over-estimation (l/h)

Fluid temperature

5°C

15°C

25°C

Fluid type

Water

0

0

0

Propylene glycol 30%

400

240

120

Propylene glycol 50%

650

500

400

i

Incorrect venting of the installation may lead to

flow variations.

∙ If you cannot reach the minimum fl ow rate, install an

auxiliary pump.

∙ Refer to the system documentation for the information

necessary for installing the auxiliary pump.

∙ If you cannot achieve the recommended fl ow rate, adjust

the circuit pressure on the control box and, if necessary,

use the fl ow rate adjusting tap on the hydraulic module.

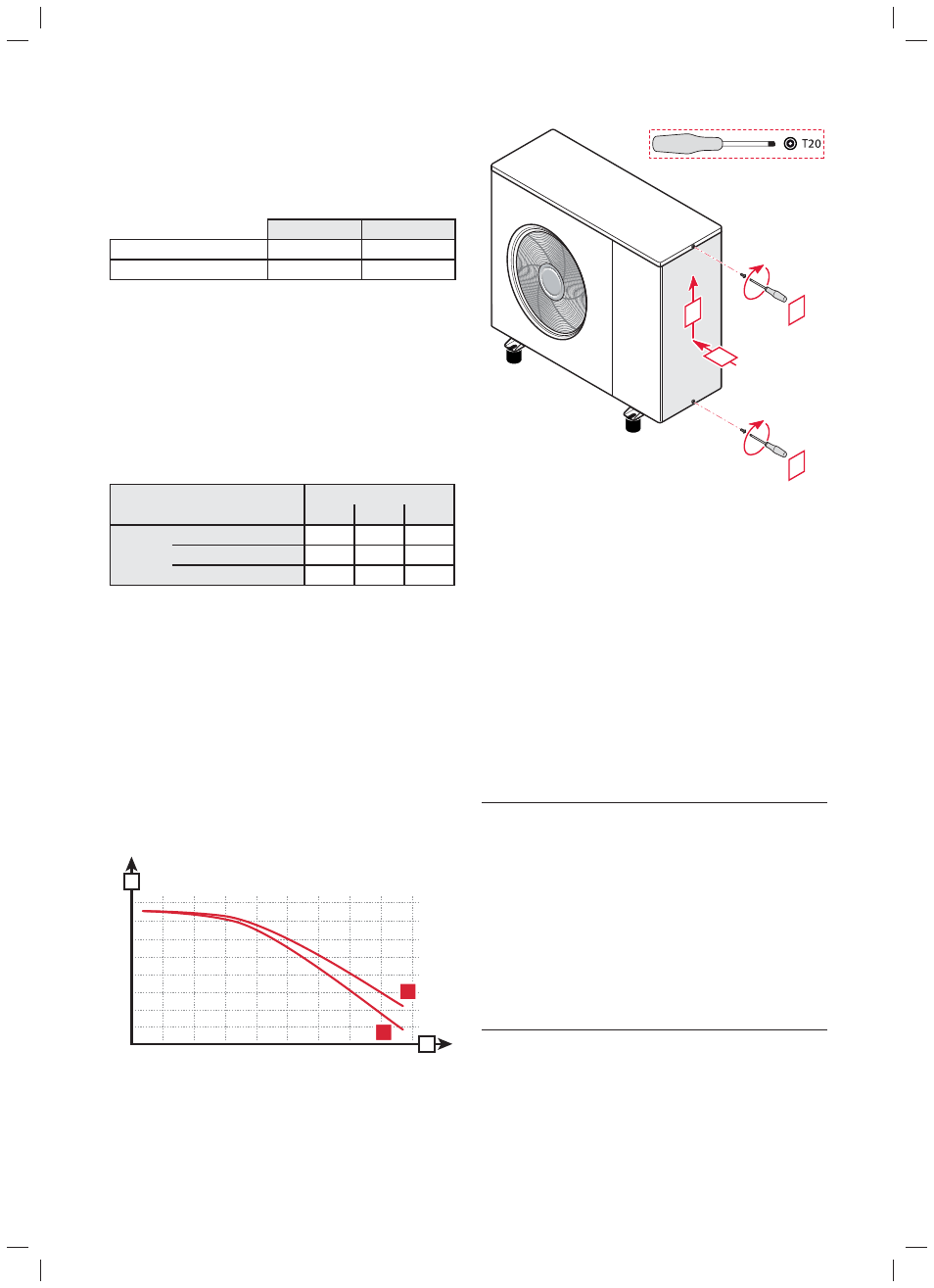

5.4.2.1 Available pressure in hydraulic circuit of the

heat pump

A

B

0

10

20

30

40

50

60

70

80

500

0

1000

1500

2000

1

2

Key

1 Envirosorb3 8 (with the water circuit at 20 ° C)

2 Envirosorb3 11 (with the water circuit at 20 ° C

A Available pressure (kPa)

B circuit

fl ow rate (l/h)

5.5

Installation of side panel

C

C

B

A

5.6 User

information

After completing the installation:

∙ Explain to the user the system operation.

∙ Draw special attention to the safety instructions that the

user must follow.

∙ Inform the user of the necessity to ensure that the system

is regularly maintained (maintenance contract).

∙ Explain to the user how to check the water level/fi lling

pressure of the system.

∙ Answer any questions the user may have.

6

Maintenance

a

Danger!

Risk of injury due to unintended intervention on

the refrigerant circuit!

The device contains refrigerant fluid and must be

handled with care. Any work carried out on the

refrigerant circuit must be conducted by qualified

engineers.

•

Only work on the refrigerant and cooling circuit

if you are a trained and approved specialist

equipped with appropriate protective equip-

ment.

•

Perform draining and filling operations in a

properly ventilated area.

•

Avoid any contact with the skin or eyes.