Mounting and installation – Glow-worm Clearly Heat Pumps Envirosorb3 User Manual

Page 12

0020154078_00 - 02/13 - Glow-worm

12

MOUNTING AND INSTALLATION

4.2

Mounting the appliance

4.2.1

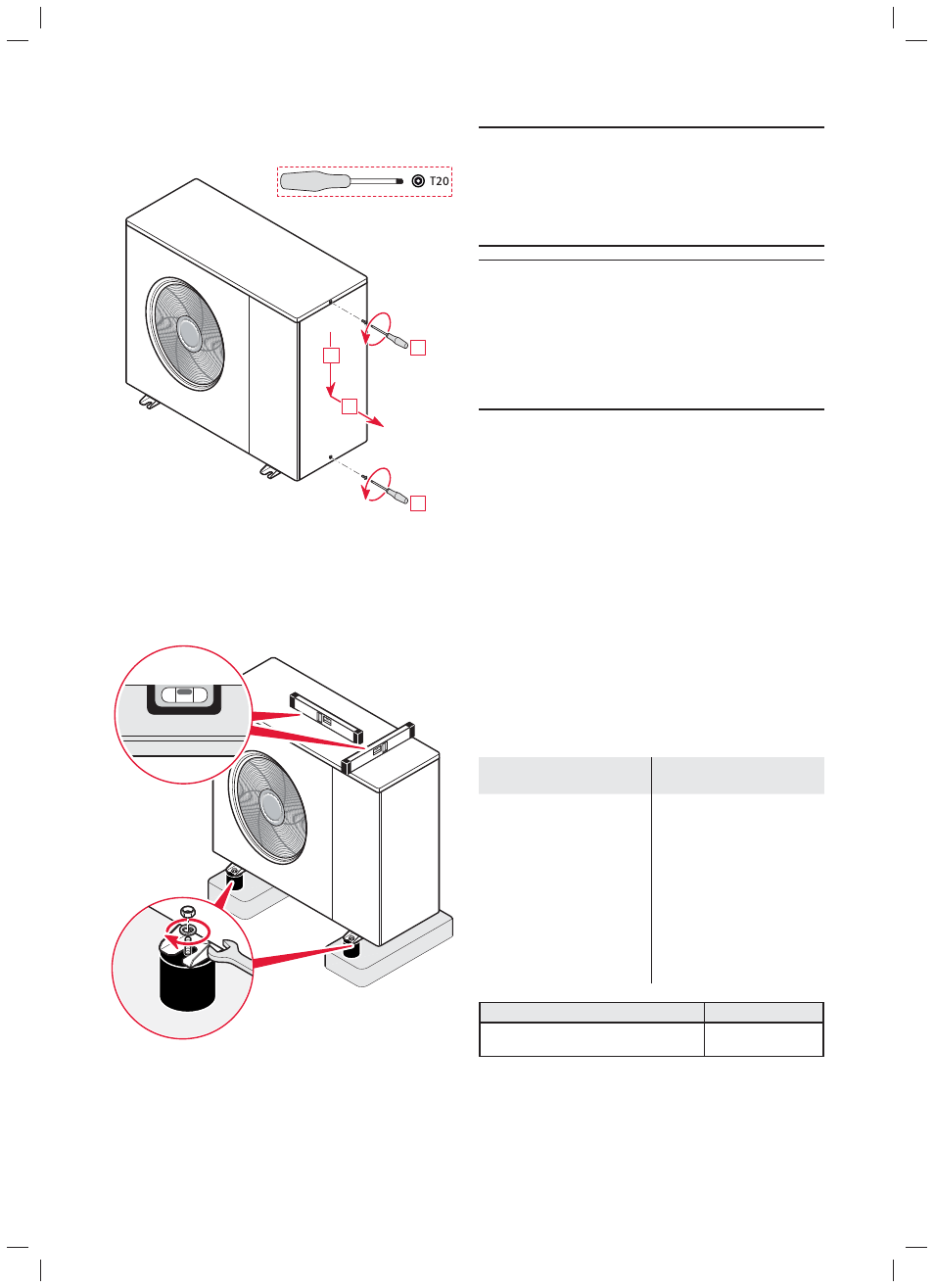

Opening the appliance

B

A

A

C

4.2.2

Positioning the appliance

i

The heat pump must be installed with the anti-

vibration pads supplied. The anti-vibration pads

are used to raise the unit, limit the transmission

of vibrations and to facilitate the discharge of

condensates.

∙ Install the appliance level so that the condensates drain

correctly.

4.3 Hydraulic

installation

b

Caution!

Risk of damage caused by contaminated lines!

Foreign bodies such as welding remnants, sealing

residue or dirt in the supply lines can cause dam-

age to the product.

•

Flush the supply lines thoroughly before instal-

lation.

b

Caution!

Risk of damage due to corrosion.

If plastic pipes that pass oxygen are used in the

heating installation, this may corrode or sludge

up the appliance’s heating circuit or the appliance

itself.

•

If you use plastic pipes that pass oxygen in the

heating installation, add a corrosion inhibitor

to the circuit water.

4.3.1 Hydraulic

connection

i

Insulate the pipes (between the heat pump and

the installation including those underground)

with an UV- and high-temperature-resistant insu-

lation.

i

In order to avoid the transmission of vibrations to

surrounding structures, flexible hoses of at least

750mm in length should be used for the hydraulic

connections from the heatpump.

∙ Do not weld pipes mounted up : this operation may

damage the seals.

∙ If the heat pump is not located at the highest point of the

hydraulic circuit, install additional bleed valves in suitable

places.

∙ Install the following components on the heat pump return

circuit.

Installation with

hydraulic module

Installation without

hydraulic module

- a drain tap

- an air separator (if

necessary)

- an anti-sludge fi lter

- an expansion tank, if the

length of the hydraulic circuit

is greater than the max.

permitted length (see table

below)

- a 3 bar (3 x 10

5

Pa) safety

valve if the hydraulic module

does not have one

- a drain tap

- an air separator (if

necessary)

- an anti-sludge fi lter

- an expansion tank suitable

for the complete hydraulic

installation

- a 3 bar (3 x 10

5

Pa) safety

valve

- a pressure gauge

(recommended)

Max. length of the hydraulic circuit

DN 28

In the case of the installation of a module

without an expansion tank

30 m