Start-up – Glow-worm Clearly Heat Pumps Envirosorb3 User Manual

Page 17

0020154078_00 - 02/13 - Glow-worm

17

START-UP

5

Start-up

∙ Refer to the operating instructions before starting the

product.

∙ Check that the diff erential breaker is installed.

∙ Check that the hydraulic and electrical connections are

correct.

∙ Check that the fi lter on the heat pump return is installed.

∙ Check the airtightness of the connections.

∙ Open all the hydraulic circuits’ valves.

5.1

Filling the hydraulic circuit

i

We recommend that you use propylene enriched

with corrosive inhibitors.

∙ Do not dispose of glycol into drains and the environment.

∙ Mix a maximum of 50% of propylene or ethylene glycol

with water. The mixture must provide anti-freezing

protection for the heat pump hydraulic circuit.

∙ Use an antifreeze test kit to ensure accurate dosing.

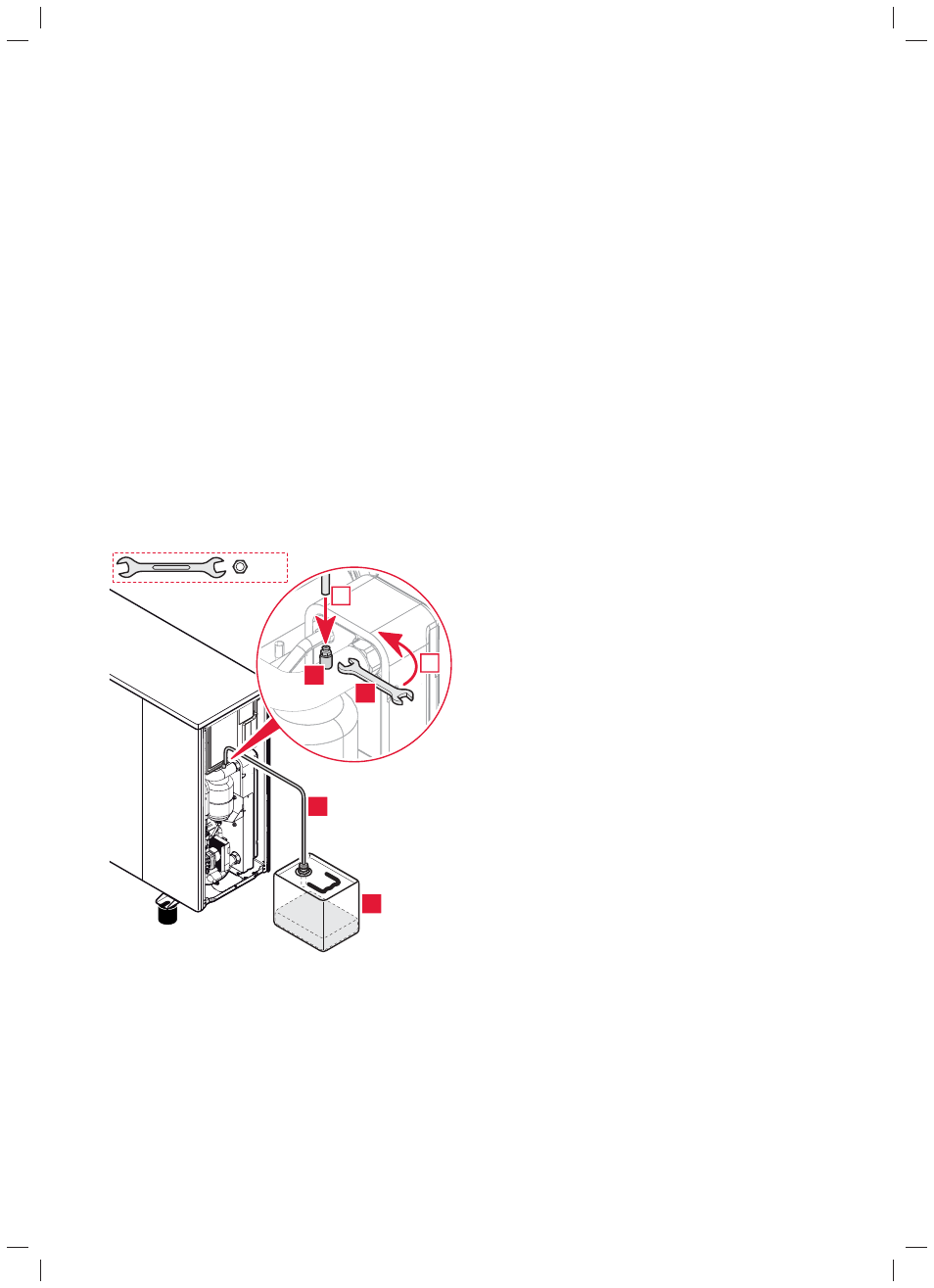

A

B

2

1

4

3

14mm

Key

1 Air

trap

2 Flat wrench (*)

3 Hose

4 Deposit

(*)

(*) Not

included

∙ Connect one end of the hose to the tap (A).

∙ Insert the other end of the hose (3) into the container

during the venting of the circuit.

∙ Using a fl at wrench, open the tap a ¼ turn (B) in order to

remove the air present in the glycol circuit, then close it

quickly (in order to avoid emptying the circuit).

∙ In order to bleed the hydraulic circuit of the heat pump

during the fi lling, use a fi lling pump.

∙ Put the heat pump circuit under pressure between 1.5 and 2

bars.

i

The hydraulic circuit pressure may decrease dur-

ing the first month following the commissioning

of the installation. It may also vary in accordance

with the outdoor temperature.

5.2

Activating the heat pump

∙ Ensure that the setting of the maximum temperature of

heating fl ow is compatible with the installation.

∙ Refer to the system installation manual in order to fully

activate the installation.

∙ Switch ON the circuit breaker which is located on the

electrical panel and connected to the heat pump.

5.3

Checking the operation of the device

∙ Ensure that the external regulators (thermostat, external

sensor, ...) send a request to the heat pump. In the case of

a multi-zone confi guration, perform the test zone by zone

and ensure that the appropriate zone gets warmer.

∙ Ensure that all the heating circuit’s thermostatic valves are

open.

∙ Balance the heat emitters, if necessary.

5.4

Adjustment of HP circuit fl ow

5.4.1

Bleeding the hydraulic circuit

i

If the swimming pool option is installed on the

circuit put the kit's 3 way valve on AUTO position.

∙ Connect one end of the hose to the tap.

∙ Insert the other end of the hose into the container in order

to recover any residual glycol during the venting of the

circuit.

∙ Close the shutoff valves at the rear of the heat pump.

∙ Pressurise the hydraulic circuit.

∙ Using a fl at spanner, open the bleed valve.

∙ Open the lower shutoff valve at the rear of the heat pump.

∙ When liquid comes out of the pipe, close the bleed valve

∙ Check that the hydraulic circuit pressure is between 1.5

and 2 bar. Otherwise, top up the hydraulic circuit.

∙ Completely open the two shutoff valves at the rear of the

heat pump.

∙ Remove the hose and the container.