ENMET SDS-97D User Manual

Page 9

SDS – 97D Sensor / Transmitter

ENMET Corporation

7

2.3.1 Automatic Zeroing

O

XYGEN

S/T:

Oxygen S/T, 0 – 30% by volume, do not require the automatic zeroing step, proceed to section 2.3.2 automatic

calibration.

T

OXIC

S/T:

If the air around the sensor/transmitter contains significant levels of the target gas or interference gases, the sensor

must be exposed to a source of fresh, clean air to perform an automatic zeroing procedure. Kits are available from

ENMET

Corporation that includes a cylinder of 20.9% oxygen, free of contaminants. The recommended flow rate of air from a cylinder

is 0.5 liters per minute.

Expose the sensor to fresh clean air for at least 30 seconds. Press and release the Calibration & Zeroing Pushbutton Switch.

After the switch is released, if the signal from the sensor is within the established Zero (clean) range, the sensor/transmitter

display is forced to zero. If the sensor reading is too high or too low, zeroing will not take place.

N

OTE

:

Under certain conditions, the display may be off 1 display unit.

If the sensor/transmitter does not read zero and continues to read more than several display units above zero, expose the sensor to

clean air from a cylinder of 20.9% oxygen for 2 minutes. After 2 minutes, press and release the Calibration & Zeroing

Pushbutton Switch again. If the display still does not zero, the sensor may need to be replaced.

2.3.2 Automatic Calibration

ENMET

Corporation makes available a calibration kit that contains the stipulated calibration gas and a calibration adapter.

With reactive gases it is imperative that the proper regulator, tubing and calibration cover be used. Failure to do so, may cause

inaccurate and/or failed calibrations. Contact your local distributor or

ENMET

for more information.

See Table 4 for calibration gas values and replacement cylinder part numbers.

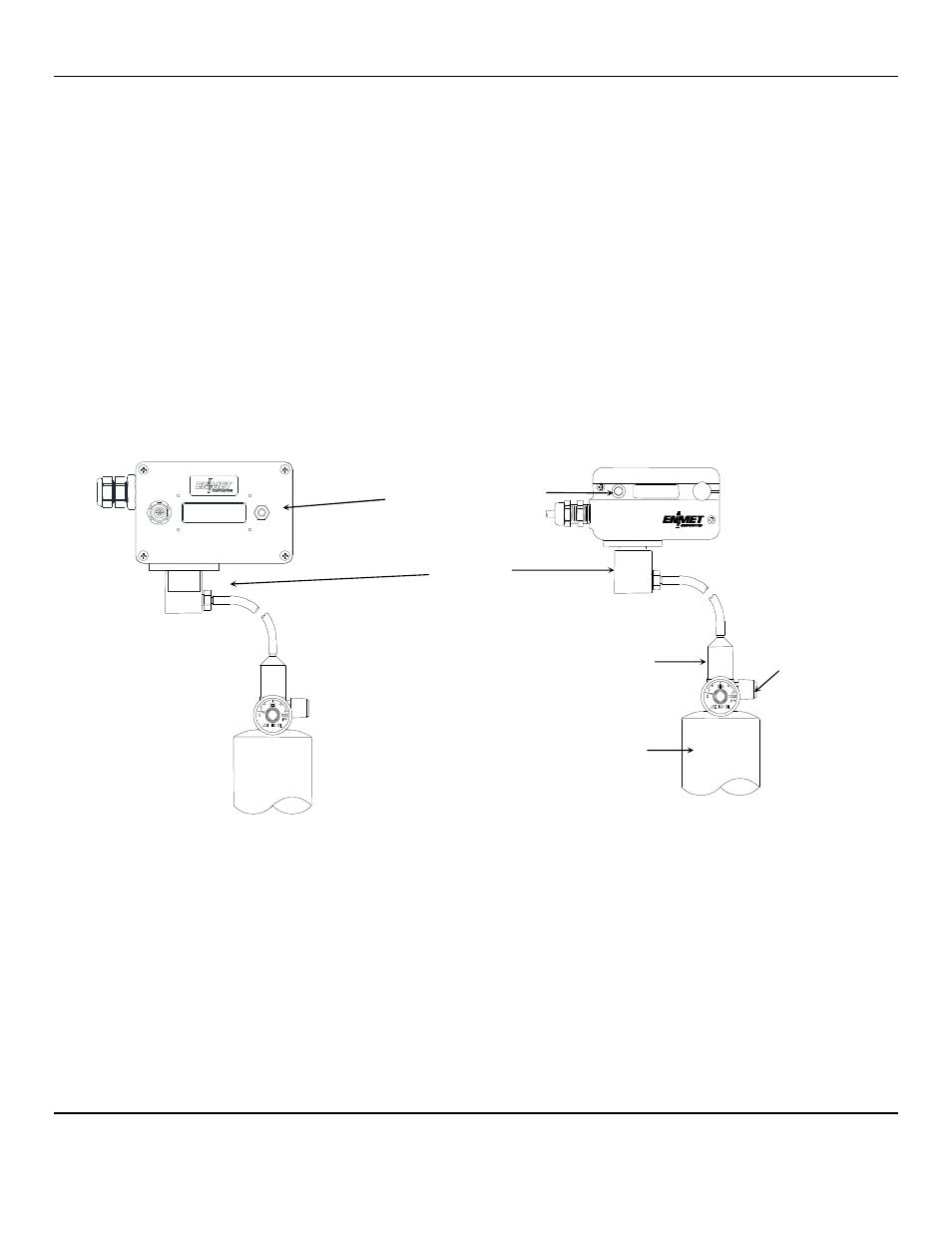

Figure E: Calibration with Gas

Screw the regulator valve of the calibration adapter onto the calibration gas cylinder, and open the flow control valve. Put the

cup over the sensor. See Figure E. After 1-3 minutes, when the display stops changing, press the calibration switch.

If the sensor output is within the calibration range, the display changes to the value of the contents of the calibration gas.

Example if calibrating with 50

PPM

CO, the display changes to “0050”.

N

OTE

:

Under certain conditions, the display may be off ± 1 display unit, Hydrogen may be off ± 20 ppm.

W

ARNING

:

If at this point the display does not change, calibration has not been accomplished. Check the following:

♦

Be sure that the proper calibration adapter is being used. Reactive gases can be absorbed by standard tubing. Special non-

reactive tubing should be used for reactive gases.

ENMET

calibration kits are supplied with appropriate tubing for the gas

in the kit.

♦

Be sure that the gas is not outdated. The shelf life or manufacture date is on the gas cylinder label.

♦

If sufficient fresh calibration gas is being used, try the calibration again. If the same result is obtained, the most probable

cause is a sensor with low output. Such a sensor is nearing the end of its useful life. Install a new sensor per Section 4.0,

and recalibrate.

Calibration & Zeroing

Pushbutton Switch

Calibration

Adapter

Gas Cylinder

Calibration

Cup

Flow Control

Valve