ENMET AM-5150 User Manual

Page 18

AM-5150

ENMET Corporation

16

5.3 Sensor Replacement

The MOS sensor is durable, it can be purged of contaminants by operating in PURGE for a sufficient length of time and at

regular intervals.

Gross contamination usually occurs during unavoidable misuse. Close exposure to an open gas flame, submersion of the sensor

in a liquid, or continuous exposure to heavy concentrations of industrial vapors will grossly contaminate a sensor. A grossly

contaminated sensor causes a continuous alarm.

If a sensor fails to calibrate, replace it.

P

ROCEDURE

:

W

ARNING

:

Power must be removed from the

AM-5150

before this or any internal procedure. Failure to do so may cause

damage to equipment, bodily injury or death.

1.

Obtain a new sensor assembly. Make sure the sensor type is identical to your original sensor

Sensor marking is on side of sensor see Figure 9

(Example: 813-4 the first 3 digits are sensor ID the 4 digit indicates a 4-wire sensor).

2.

Disconnect the instrument for power.

3.

Disconnect the orange, brown, blue and yellow sensor wires.

4.

Unscrew the assembly from the sensor enclosure.

5.

Remove the bad sensor.

6.

Replace with the new sensor and reconnect the wires (See Section 3.2.1).

N

OTE

: The user must perform the four color-coded wiring attachments when replacing the sensor. If the yellow signal wire

is not connected to the terminal block, use supplied wire nut.

7.

Reconnect the instrument to power and verify sensor heater voltage. (See Section 3.2.1)

8.

Recalibrate the instrument (See Section 5.3.1).

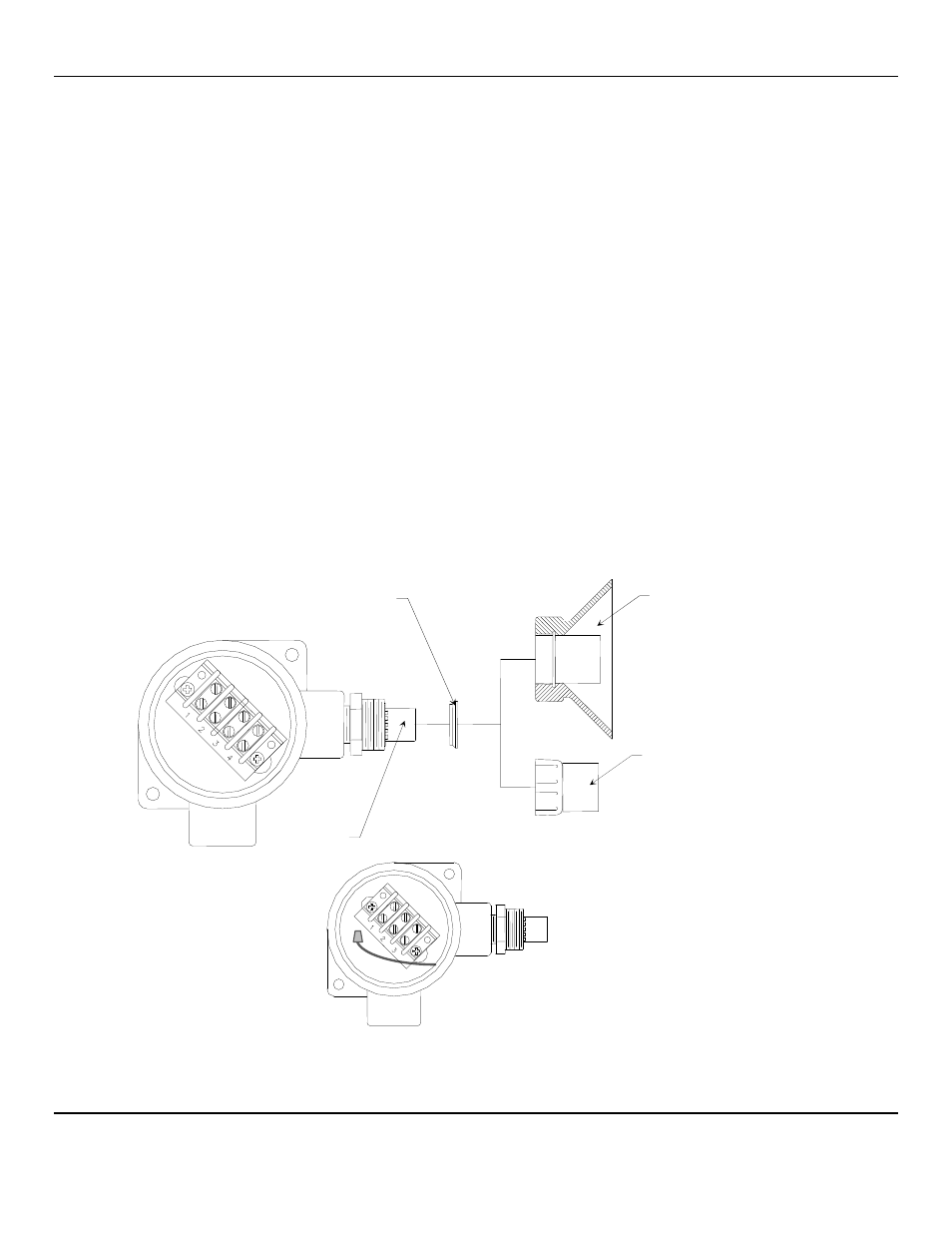

Figure 9: AM-5150 Sensor Replacement

After the new sensor assembly has been installed, it is suggested to allow the sensor to stabilize for at least 3 – 4 hours,

preferably over night.

Sensor

Spacer Ring

*Replace facing direction as shown

Optional Splash Shield

Standard Sensor Shield

View of 3-wire Terminal

View of 4-wire Terminal