Maintenance, Warning, Important – EarthQuake W2700B User Manual

Page 15

Operator's Manual

27-Ton Log Splitter, W2700

Check for parts online at

www.getearthquake.com or call 800-345-6007 M-F 8-5 CST

15

NORMAL OPERATION:

1. Set up the log splitter on a clear, level area and block the

wheels. Make sure that the suction port on the reservoir is

always on the lower side of the log splitter.

note: the log splitter can be used to split logs with the

beam in both the horizontal and vertical positions. in ei-

ther position, make sure the beam is locked into position

with its respective spring-loaded lock pin.

2. Place a log on the beam against the foot plate. Make sure

that the log is placed securely on the foot plate and flat

against the beam.

3. Depress the control valve handle forward toward the log so

that the cylinder will drive the wedge into the log. Extend

the cylinder until the log splits or the wedge travels to the

end of its stroke. If the log has not completely split after the

cylinder has reached the end of its extension, retract the

cylinder. Retract the cylinder by pulling back on the control

valve handle. SEE FIGURE 17 AND/OR 18

note: For operation in wooded areas, obtain a spark

arrestor for the exhaust system from the manufacturer

of your engine. You can also consult the "Warnings and

safety precautions" section of this manual.

MAINTENANCE:

1. Consult the operating and maintenance instructions of the

Engine Operator’s Manual for engine care and maintenance.

2. Always check the oil level of the hydraulic reservoir before

operation. Oil must be no more than two inches from top of

tank when the wedge is in the returned position. Operating

the log splitter without an adequate oil supply will cause

severe damage to the hydraulic pump.

3. If the wedge becomes dull or nicked, it can be removed and

sharpened. While the log splitter is in the horizontal posi-

tion, remove the hair pins and pin that connects the wedge

to the hydraulic cylinder. Then remove the eight bolts and

nuts that secure the wedge to the splitting platform. The

wedge can now be removed and sharpened.

4. All replacement parts must meet manufacturer’s specifica-

tions.

5. Check air pressure of tires before each use. Maintain pres-

sure to 60 psi or to the recommended maximum pressure

printed on the tire.

6. Grease wheel bearings annually.

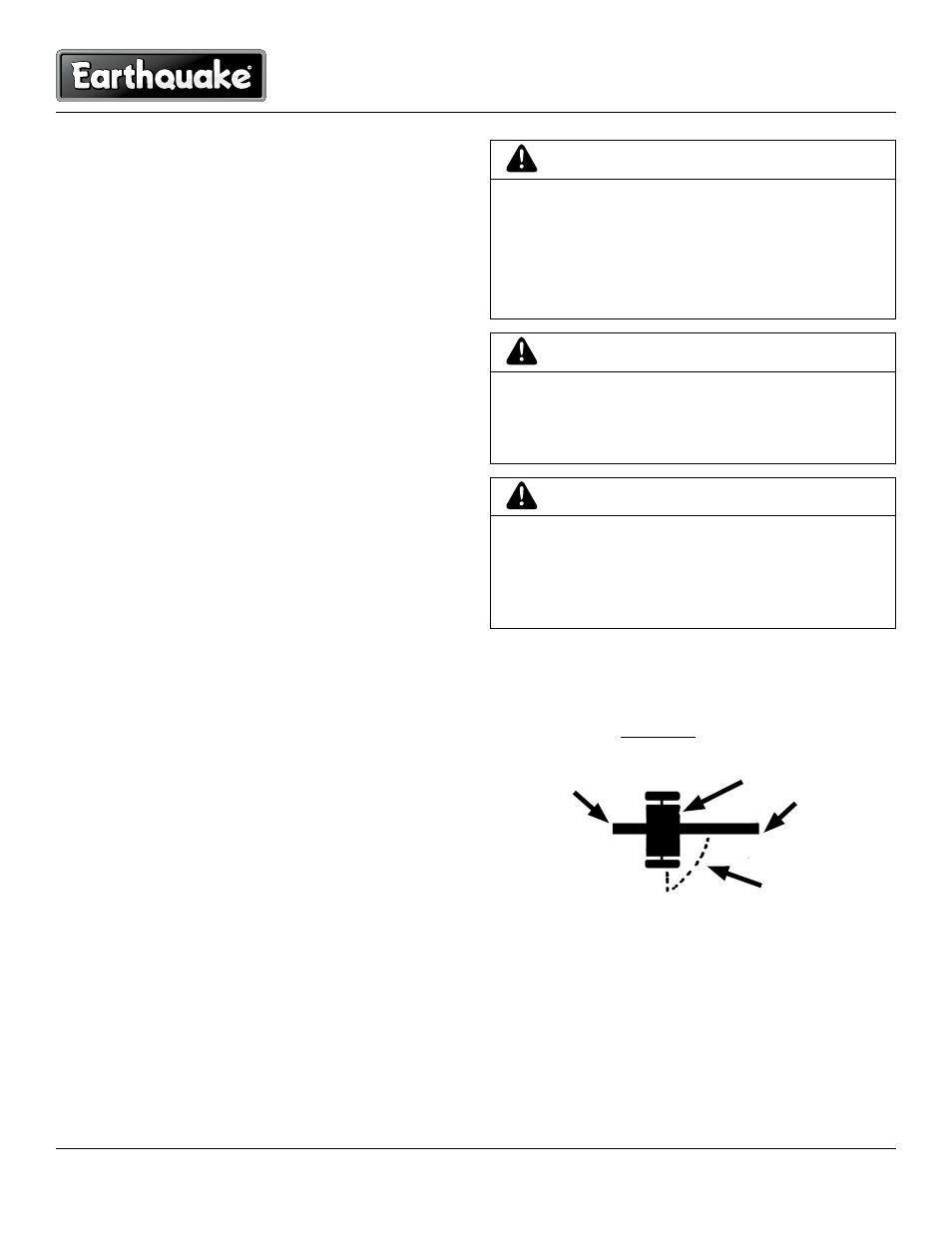

Figure 19

Top View

foot plate

engine

tongue

operator zone

WARNING

ALWAYS WEAR SAFETY GLASSES DURING OPERA-

TION.

kEEP HANDS AND FEET CLEAR OF RAM, STRIPPER

BAR AND FOOT PLATE AT ALL TIMES.

DO NOT OPERATE LOG SPLITTER IF THE OIL LEVEL IS

MORE THAN TWO INCHES FROM TOP OF TANk WHEN

THE WEDGE IS IN THE RETURNED POSITION.

IMPORTANT

LEAVING THE VALVE IN THE “ACTUATE” POSITION AT

THE END OF THE STROkE MAY DAMAGE THE PUMP.

ALWAYS USE ExTRA CARE WHEN SPLITTING LOGS

WITH ENDS NOT SQUARE.

IMPORTANT

TO ExTEND THE LIFE OF THE HYDRAULIC CYLINDER,

AVOID “BOTTOMING OUT” WEDGE PLATE TO THE

FOOT PIECE. TO CONFORM WITH INDUSTRY SAFETY

RECOMMENDATIONS, THE WEDGE STOPS TWO INCH-

ES FROM THE END OF THE STROkE.