Drilling fluid requirements, Funnel viscosity, Fm25 operator’s manual – Ditch Witch FM25 User Manual

Page 43

Drilling Fluid Concepts - 42

FM25 Operator’s Manual

Drilling Fluid Requirements

CMW

Drilling Fluid Requirements

1.

Determine drilling conditions and choose appropriate drilling fluid mix.

2.

Estimate amount of supplies needed and check availability.

•

Drilling fluid

•

Water supply. If more water than can be carried with the unit will be needed, arrange to transport

additional water.

•

Bentonite and/or polymer

3.

Check water quality.

•

Use meter or pH test strips to test pH of water. If pH is below 9.0, add 1 lb (454 g) soda ash per

tank. Test and repeat until pH is between 9 and 10.

•

Check water hardness using hardness test strips. Treat with soda ash if hardness exceeds 125

ppm.

Funnel Viscosity

Viscosity is the measure of internal resistance of a fluid to flow; the greater the resistance, the higher the

viscosity. Viscosity of drilling fluids must be controlled.

To determine viscosity, you will need a Marsh funnel (p/n 259-267) and a measuring cup, available from

your Ditch Witch dealer.

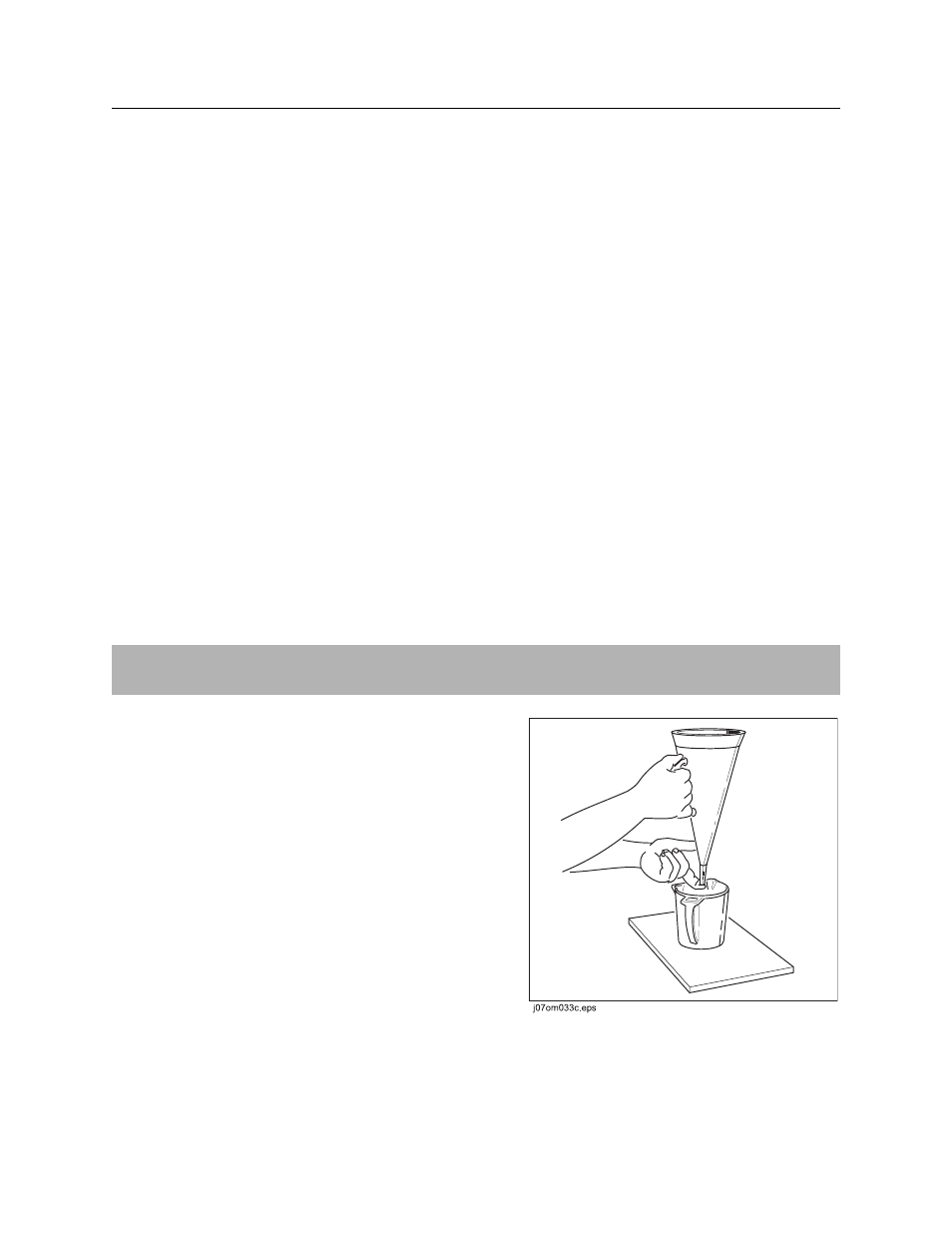

1.

Using wash hose and a clean container, take a fresh

sample of drilling fluid. The sample must be at least

1.5 qt (1.4 L).

2.

With finger over bottom of funnel, fill with fluid from

the container through the screen until fluid reaches

the bottom of the screen.

3.

Move funnel over 1 qt (.95 L) container.

4.

Remove finger from bottom of funnel and use the

stopwatch to count the number of seconds it takes for

1 qt (.95 L) of fluid to pass through the funnel. The

number of seconds is the viscosity.

5.

Thoroughly rinse measuring cup and Marsh funnel.

IMPORTANT: Make sure Marsh funnel is clean and free of obstruction and that you have a stopwatch

available for timing the viscosity.