Figure 6 – Bimba Ultra Slide Rodless Cylinder User Manual

Page 4

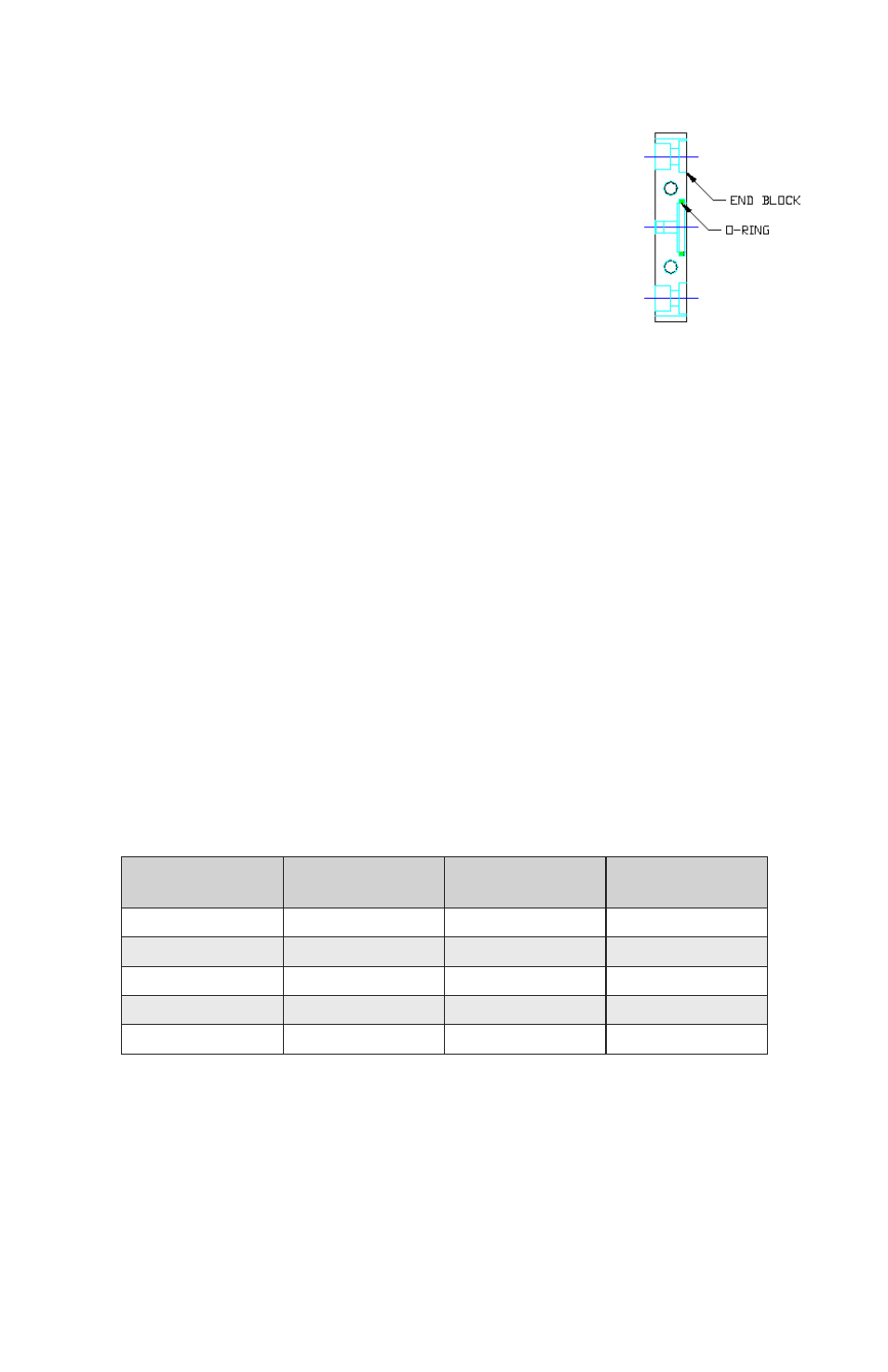

Figure 6:

Bore Size

Torque ft–lb

(N–m)

Bore Size

Torque ft–lb

(N–m)

007 (8mm)

1.6 (2.17)

09 (27mm)

20.1 (27.25)

01 (12mm)

2.1 (2.85)

12 (32mm)

50.8 (68.9)

02 (14mm)

5.8 (7.86)

17 (38mm)

50.8 (68.9)

04 (18mm)

5.8 (7.86)

31 (50mm)

179 (242.7)

06 (22mm)

12.5 (17)

Refer to Figure 6 for Steps 23–25

23. Remove the body O–ring tube seal from the large hole

in both end blocks.

24. Clean the end blocks and the O–ring groove of any grease

or contaminants.

25. Lightly lubricate the new O–rings. Stretch the O–rings

slightly and place them in the grooves by hand.

26. Apply a coating of lubricant to the inside surface of the

tube. Best performance will be achieved when the lubri-

cant is applied evenly over the whole surface.

27. Insert the tube through the center hole in the carriage.

28. Apply a coating of high grade bearing grease to the piston and insert it into

the tube. Use your fingernail to deflect the lip of the seal to insert it in the tube.

Again note that the orientation of the piston to the carriage must be maintained

as described previously.

29. Place the assembly back in the arbor press and with the shaft used before,

re–couple the piston with the carriage.

30. Lightly lubricate the four guide rod bearings in the carriage by hand or with a

swab. Insert the two guide rods through the bearings in the carriage.

31. Attach one end block to the guide rods. Insert the tube into the large hole in

the end block. Press firmly on the tube to seat it in the O–ring. Tighten the cap

screws finger tight only.

32. Install the second end block onto the guide rods and tube body. Fasten with

the two cap screws, finger tight.

33. Slide the carriage to one end of its stroke and tighten the cap screws at that

end to the torque specifications listed in the chart.

34. Repeat process for opposite end.

Bimba Manufacturing Company

Monee, IL 60449-0068

TEL: 708/534-8544 • FAX: 708/235-2014

Support: 1-800-44-BIMBA

Visit our website at: www.bimba.com

Form ULRI-900