Slide repair instructions – Bimba Ultra Slide Rodless Cylinder User Manual

Page 2

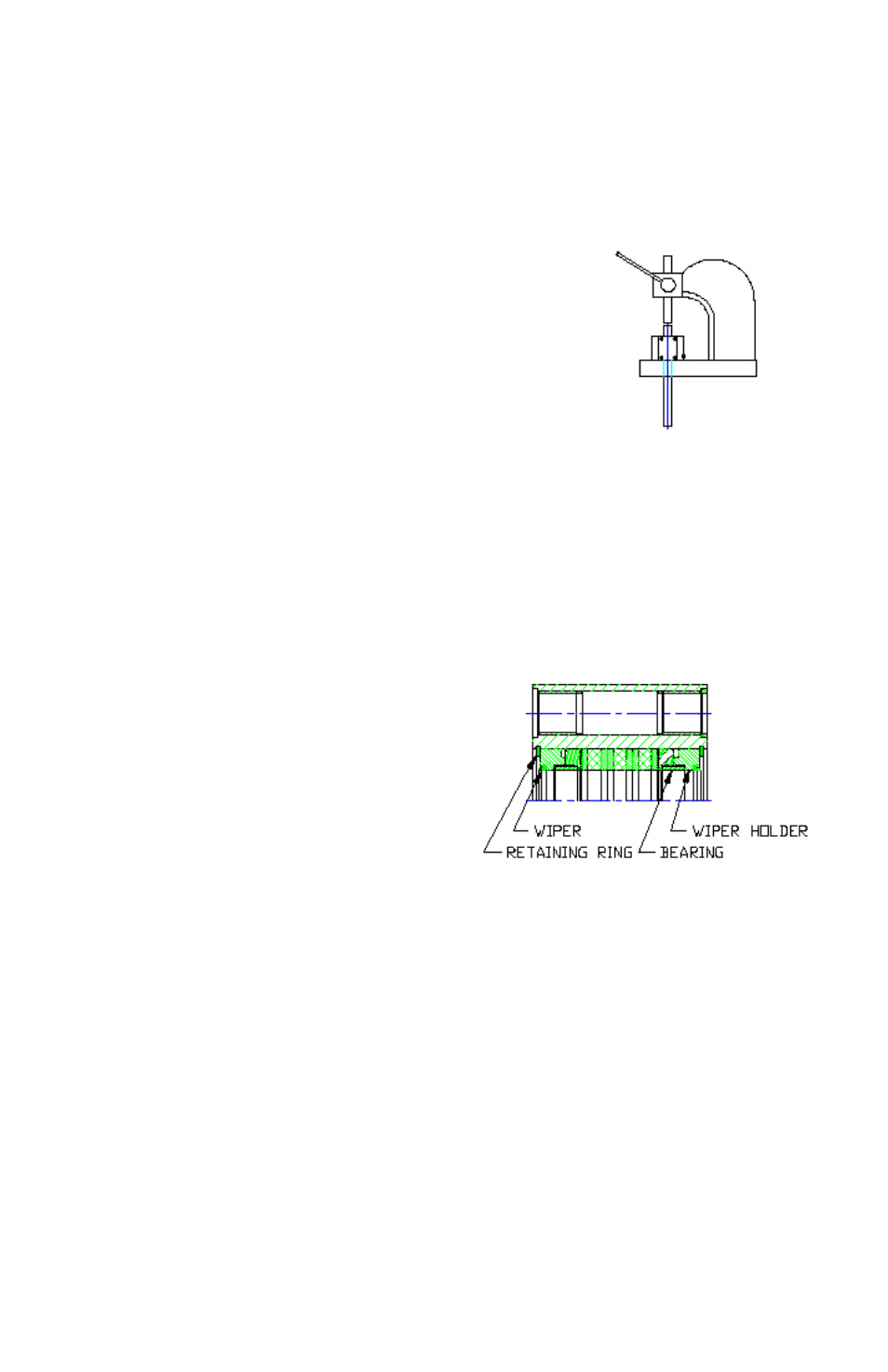

Figure 1:

Figure 2:

Refer to Figure 1 for Steps 1–7

1. Remove air pressure and fittings.

2. Wipe down and clean the unit.

3. Remove the four cap screws that fasten the end

blocks to the guide rods.

4. Remove the end blocks and the guide rods keeping

the carriage, body and piston together as a unit.

5. Remove any grease, dirt or oil from the individual

pieces.

6. Place the carriage, body and piston assembly in

an arbor press. Using a non–magnetic rod or shaft,

press on the piston to uncouple it from the carriage magnets. Do not let the

body slip out of the carriage during this operation.

7. Remove the carriage from the body leaving the piston inside the body. Place

body and piston aside.

Refer to Figure 2 for Steps 8–12

8. Remove retaining ring, wiper holder

and bearing from the center hole on the

carriage. Repeat for both ends.

9. Insert new bearings into both ends.

10. Noting the orientation of the wiper lip,

remove the old wiper from wiper holder

and insert new wipers with the same

orientation.

11. Insert the wiper holder into carriage.

12. Assemble the retaining ring into its

groove in the carriage.

Refer to Figure 3 for Steps 13–17

13. Plug the center hole of the carriage (both ends) with a clean rag or cloth to

prevent bearing contamination.

14. Pry out the four guide shaft wipers or press rings (depending on bore size and/

or option) with a screw driver or similar tool.

15. Press out the four guide shaft bearings using care not to disturb the internal

press rings.

16. For the 3/4” thru 2” bore sizes, press in the new guide shaft bearings to the

bottom of the counterbore using an arbor press. For the 5/16” thru 9/16” bore

sizes, press the bearing into the dimension shown in the chart.

17. Press in the new wipers or press rings, depending on bore size and/or op-

tions.

SLIDE REPAIR INSTRUCTIONS