Bimba Ultra Slide Rodless Cylinder User Manual

Page 3

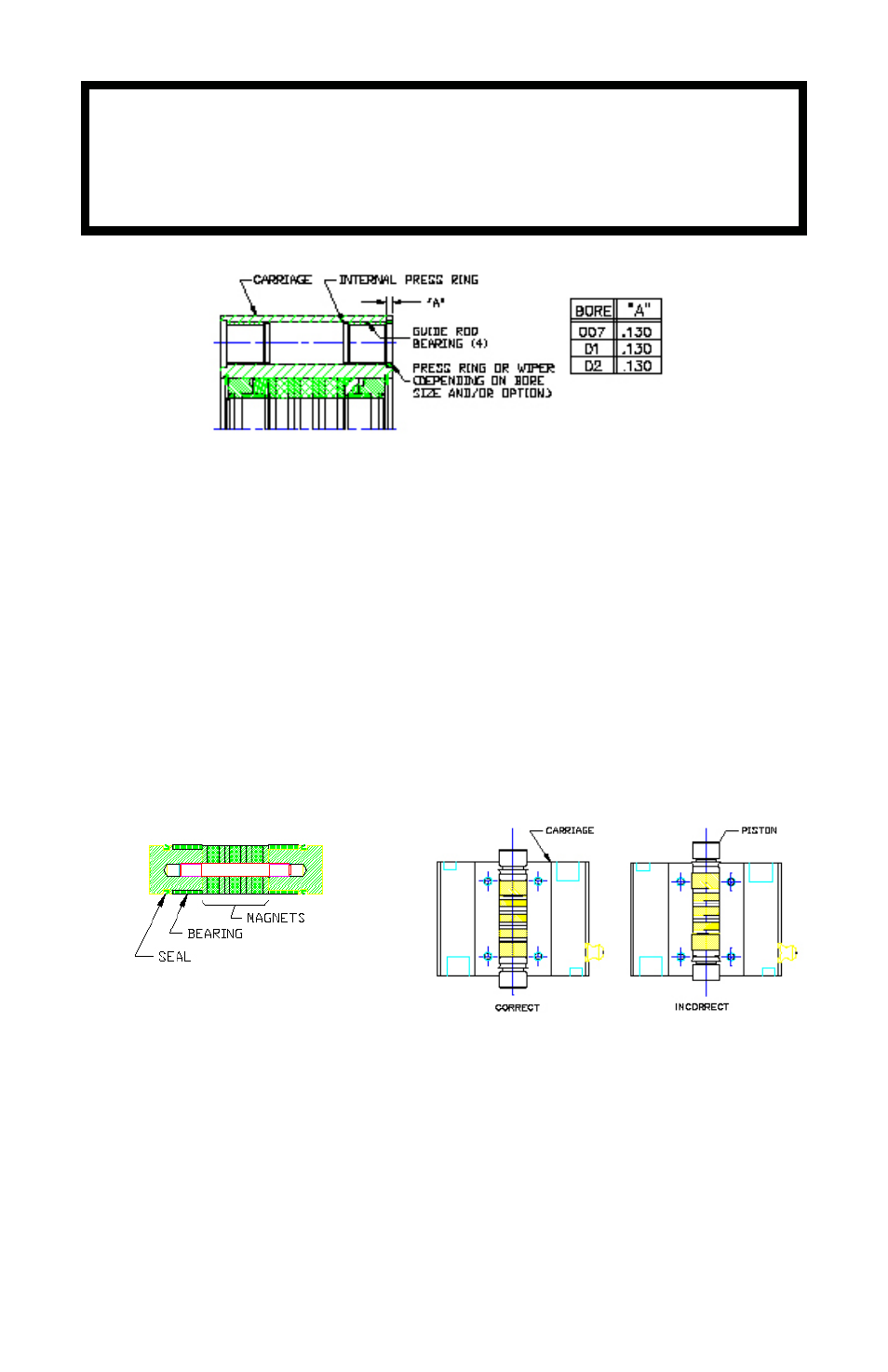

Note: The Ultran guide shaft bearings were upgraded in the second half of

2000. All new repair kits shipped after September 2000 will contain the new

style shaft bearings, which utilize internal press rings. If the Ultran assembly

being repaired does not have internal press rings, be sure to add them before

pressing the bearings in place.

Figure 3:

Figure 4:

Figure 5:

Refer to Figure 4 for Steps 18–21

18. Remove the piston from the body.

19. Using cutters, cut the seal and pull it out of the groove. Be careful not to scratch

the surfaces of the groove.

20. The new piston bearing configuration is non–repairable. If the Ultran being

repaired has split piston bearings, it should be sent to the factory for new style

piston bearings, or a new piston assembly should be ordered. Contact your

distributor for details.

21. Using the same insertion tool as Step 13, slip the seal into its groove. Be sure

the seal is oriented so the lip faces away from the bearing.

Refer to Figure 5 for Step 22

22. Place the piston on top of the carriage and note its position. The ends of the

piston should extend beyond the ends of the carriage equally. If they do not,

turn the piston end for end. This orientation of the piston and carriage must be

maintained for the rest of the assembly.