Troubleshooting, Maintenance, Machine use – Delta DC-580 20" PLANER 22-450 User Manual

Page 22: Adjusting table gibs

22

ADJUSTING TABLE GIBS

In the unlikely event of the table developing unwanted

movement during planing operations, the table can be

checked and adjusted as follows:

1.

DISCONNECT MACHINE FROM

POWER SOURCE.

2.

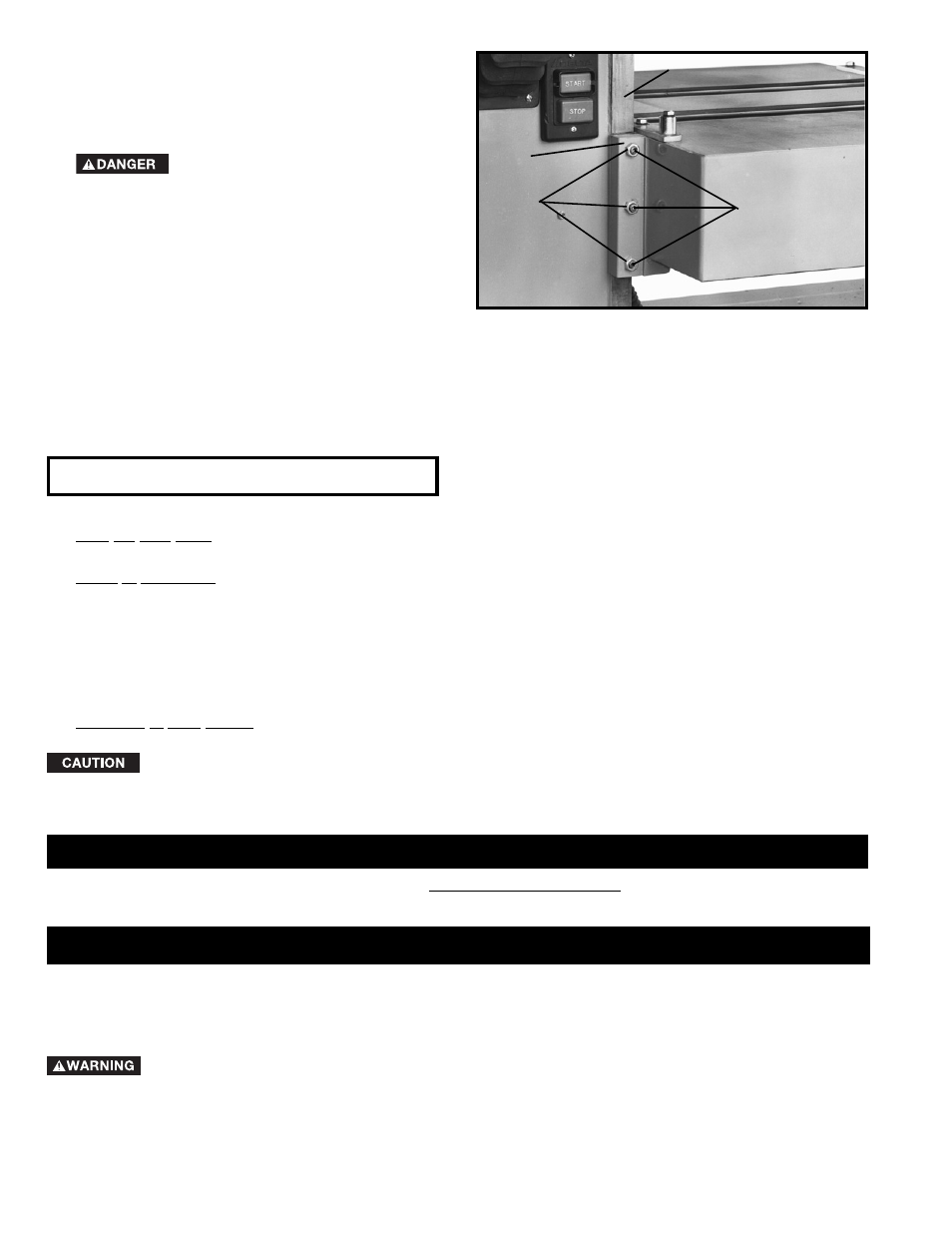

With the table in the locked position, and with a

feeler gage, measure the gap between table gib (A) Fig.

54 and table bracket (B). When set correctly the gap

should be .005".

3.

If an adjustment is necessary, loosen three locknuts

(C), and turn three adjustment screws (D) Fig. 54, as

necessary to set the correct gap.

4.

Check and adjust the gap on the other side of the

table in the same manner. Tighten six locknuts, three of

which are shown at (C) Fig. 54, after adjustment is

made.

Fig. 54

C

D

A

B

When using your machine, follow these few simple steps for achieving the best results.

1.

True Up One Face

– Feed one face of the board over a jointer, making thin cuts with each pass, until the entire

surface is flat.

2.

Plane to Thickness

– Place the side you planed in STEP 1 face down and feed the board through the planer. Plane

until this side is flat, then plane both sides of the board until you are satisfied with the thickness. Make thin cuts,

and alternate sides with each pass. If, during the planing operation, you notice the board twisting, warping, or

bowing, repeat STEP 1 and true up one face.

3.

When planing long stock, provide table extensions to support the infeed and outfeed end of the workpiece.

4.

Plane with the grain only, and keep planer table clean. Occasionally, wax the table surface to reduce friction during

the planing operation.

5.

Cross-cut to Final Length – Cross-cut lumber to final length.

THE KNIVES ON THE PLANER WILL NOT WEAR EVENLY IF THE WOOD IS FED THROUGH THE

SAME SPOT ON THE TABLE EVERY TIME. FEED THE WOOD THROUGH THE PLANER AT

DIFFERENT SPOTS ON THE TABLE TO HELP ELIMINATE UNEVEN WEAR OF THE KNIVES.

MACHINE USE

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call

the DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

5.

Raise and lower the table to its fullest range and

check to see if the table moves up and down without

binding.

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth. NEVER

use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear ANSI Z87.1 safety glasses while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also,

check for blown fuses or open circuit breakers in the line.