Checking and adjusting feed roller belt tension – Delta DC-580 20" PLANER 22-450 User Manual

Page 16

16

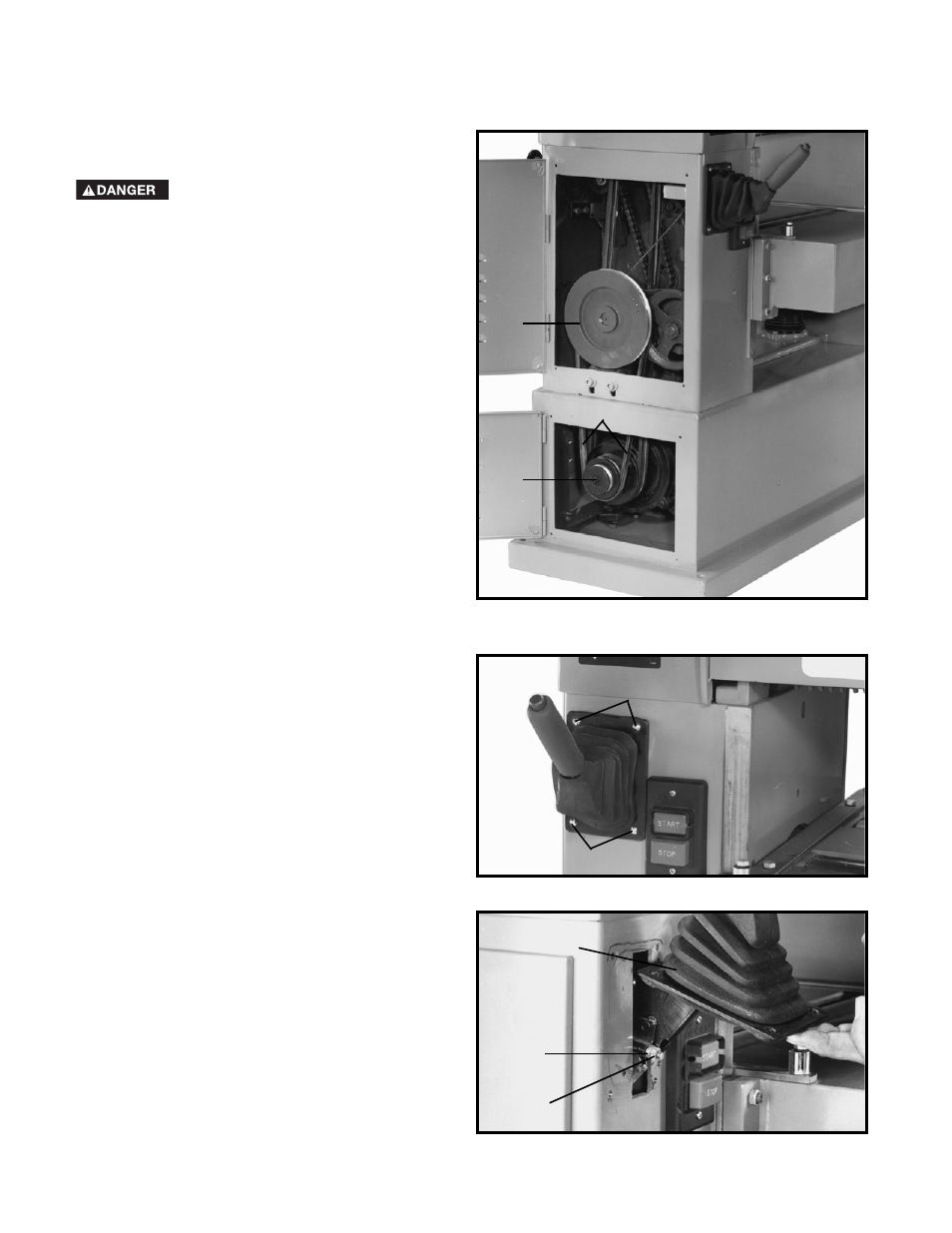

Fig. 30

CHECKING AND ADJUSTING FEED ROLLER BELT TENSION

Proper tension on the feed roller belt is obtained when there is approximately 1/2" deflection, using light finger pressure

on feed roller belt (A) Fig. 30. midway between pulleys (B) and (C), with feed roller lever (D) engaged. If an adjustment is

necessary, proceed as follows:

1.

DISCONNECT MACHINE FROM

POWER SOURCE.

2.

Engage feed roller lever (D) Fig. 30.

3.

Remove four screws (E) Fig. 31, which hold

engagement lever boot (F) to the machine.

4.

Raise boot (F) Fig. 32, to gain access to adjustment

hardware.

5.

Loosen jam nut (G) Fig. 32, and tighten or loosen ad-

justment hex nut (H) as necessary to adjust feed roller belt

tension.

6.

Tighten jam nut (G) Fig. 32, against hex nut (H) after

adjustment is made.

7.

Replace the engagement lever boot (F) Fig. 32.

Fig. 31

Fig. 32

B

C

A

E

E

F

H

G