Operation, Shoping or routing when using the fence as a guide – Black & Decker SR650 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

0

m

0

CUiriNGCInaf

BOTH Of CUT

OUTFEED FENCE

INFEED FENCE

WORK

CORREa

INCORREa

WORKPIECE

CUTTER

COlUR

TABLETOP

Operation

The following is an example of the setup and operational procedures

when using the fence, collars and starting pin. Please review this

information carefully before turning on the power to avoid damage to

the machine or personal injury.

Shoping or Routing When Using the Fence as a Guide

Using the fence is the safest and most satisfactory method of shaping

and routing and this method should always be used when the work

permits. Almost all straight work con be shaped using the fence as follows:

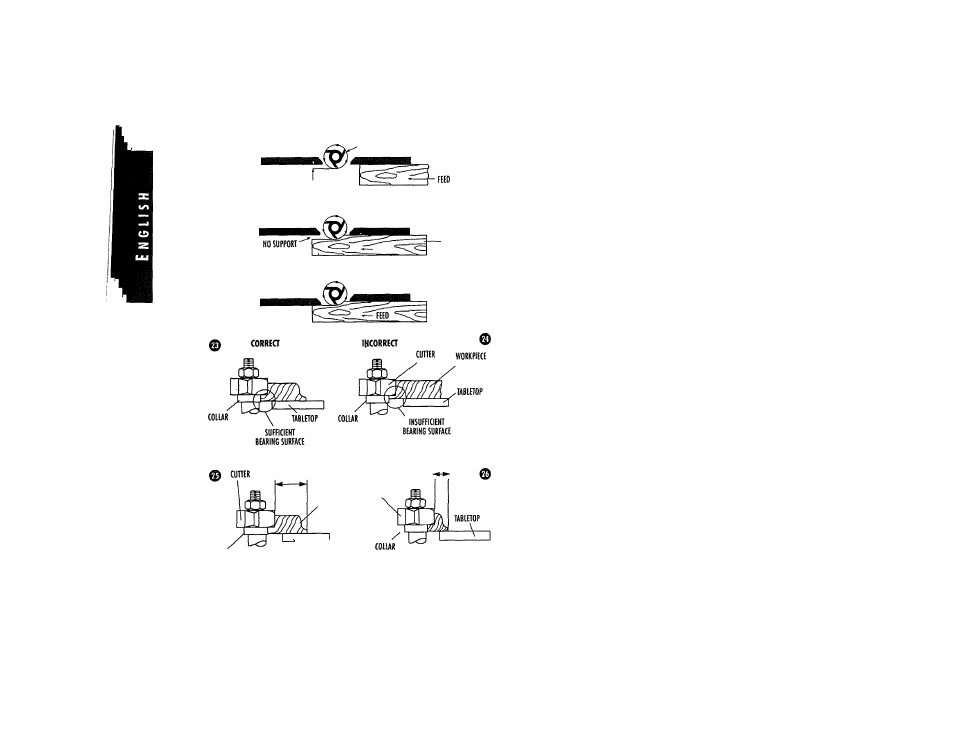

1. For average work, where a portion of the original edge of the work

is not touched by the cutter, both the front and rear fences are in a

straight line, as shown in Figure 20.

2. When the operation removes the entire edge of the work, e.g., in

jointing or making a full bead, the shaped edge will not be

supported by the rear fence when both fences are in line, as shown

in Figure 21. In this case, the work should be advanced to the

position shown in Figure 21 and stopped. Then turn the machine off.

3. The outfeed fence and infeed fence should then be adjusted to

contact the work, as shown in Figure 22. The outfeed fence will

then be in line with the cutting circle. Refer to Figure 12 which

illustrates "Adjusting the Fence."

NOTE; When cutter rotation is reversed from that shown in

Figures 20, 21 and 22, feed direction will also be reversed

and infeed and outfeed fence identification will reverse.

4.

Avoid heavy cuts. Begin by positioning cutter and fence to remove

only a small portion of the final cutter form. Increase cutter

exposure with each successive pass by moving fence and/or cutter

height until desired form is cut on workpiece. After gaining

experience with a particular cutter, you will learn how many passes

with accompanying fence and cutter adjustments are necessary to

produce a safe and satisfactory result. Remember, taking loo great

a cut or feeding the workpiece too fast can cause damage to the

piece and loss of control with possible injury.

5. When beginning the shaping operation, apply most pressure to that

portion of the workpiece supported by the infeed fence taking care

to keep your hands safely away from the cutter. When more than

to