Cuning deck engagement adjustment, Speed cdntrol adjustment (see figure 11) – Bolens 13AG678G022 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CUniNG DECK ENGAGEMENT ADJUSTMENT

The

cutting

deck

engagement

may

be

adjusted

to

make certain deck is disengaged when lift lever is in

the

BLADES

OFF

position.

Correct

adjustment

as

follows.

With the engine off, place the lift lever in the highest

cutting

position

(first position).

Remove the cotter pin

and flat washer which secure the disengagement rod

to the stabilizer shaft assembly. Shorten the rod by

threading it in until the ferrule is against the back of the

slot in the lift shaft assembly, and the rod lines up with

the hole in the stabilizer shaft. For more belt tension

the

disengagement

rod

must

be

lengthened.

To

decrease belt tension the disengagement rod must be

shortened.

Check the adjustment by placing the lift lever in the

BLADES OFF position. The deck should move up and

forward, allowing the belt to become loose. Start and

test

for

disengagement.

Repeat

procedure

as

neces

sary.

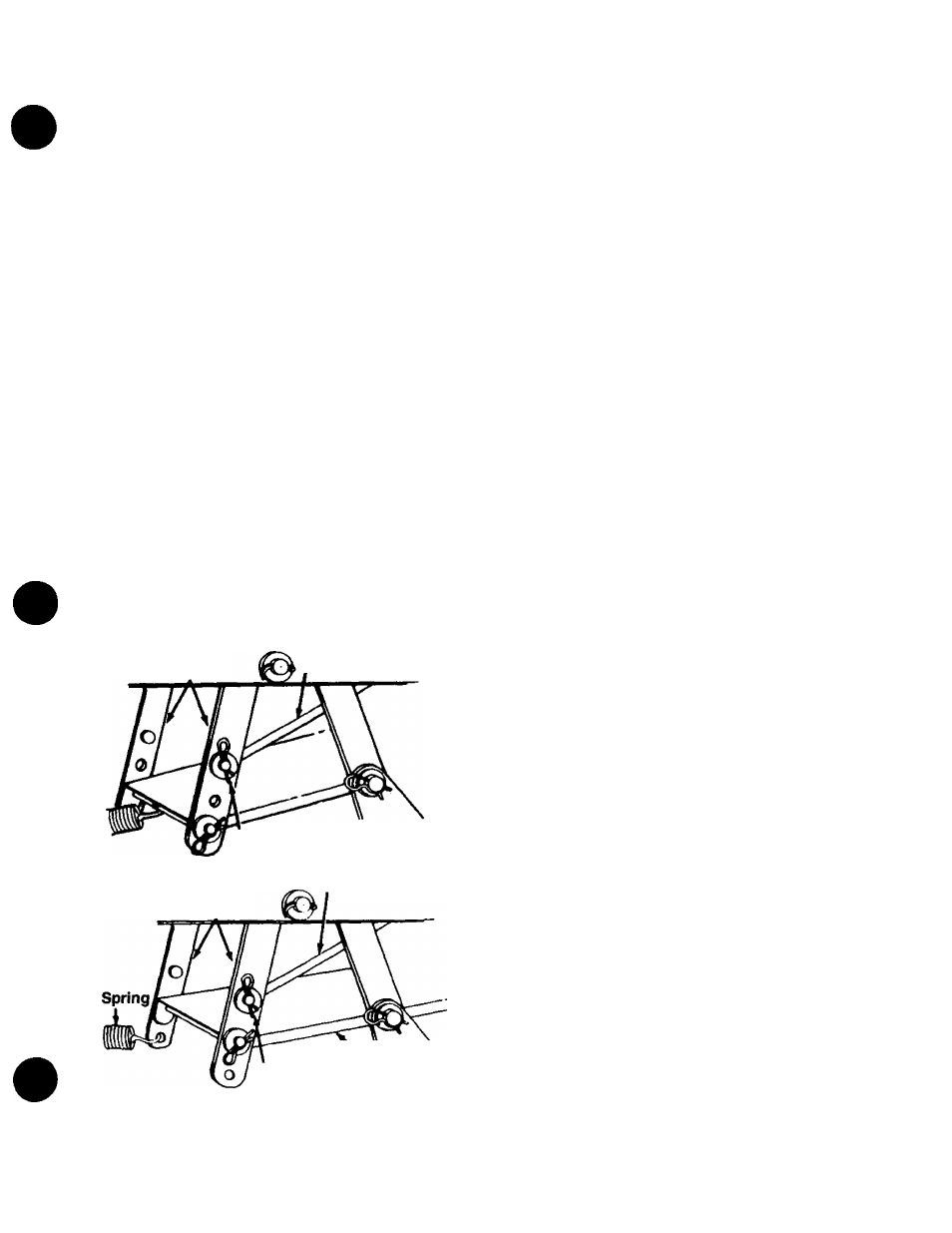

Stabilizer Shaft

Assembly

Disengagement Rod

Flat Washer

Hairpin Clip

36“and

38" Decks

Stabilizer Shaft

Assembly

Disengagement Rod

siabmzer Plate

Flat Washer

Hairpin Clip

42" and

46“ Decks

FIGURE 10.

SPEED CDNTROL ADJUSTMENT (See figure 11)

NOTE: When operating the unit initially or after replac

ing the belts, there will be little difference between the

highest two speeds until after the belts have gone

through a break-in period and have seated themselves

into the pulleys.

If the full range of speeds cannot be obtained on your

unit, adjust the speed control as follows.

1.

Adjust the speed control lever by pushing the

clutch-brake

pedal

forward until the

stop

on the

brake rod is against the frame. See figure 13.

Have

another

person

hold

the

pedal

in

this

position

as

you

make

the

following

adjustment.

Place

the

speed

control

lever

in

parking

brake

position. Remove the hairpin clip and flat washer,

and adjust the ferrule on the rod so it is against

the back end of the slot. See figure 11. Then

lengthen

rod

one

more

turn.

Reassemble

and

secure with the flat washer and hairpin ciip.

2.

Adjust the speed control link as follows to obtain

the correct neutral adjustment.

A. Start the engine.

B. Place the shift lever in Neutral position.

C.

Place the speed control lever in high speed

position.

D.

Release

the

clutch-brake

pedal

completely,

then slowly depress the pedal all the way (to

park position). Hold the pedal in this position.

E. Turn the engine off.

F.

After

engine

stops

completely,

release

the

clutch-brake pedal.

G. Position speed control lever as follows.

7-speed

units—Place

speed

control

lever

in

second position.

6-speed

units—Place

speed

control

lever

between first and second position (hold in this

position).

5-speed

units—Place

speed

control

lever

in

first position.

H.

Remove the cotter pin and flat washer which

secures the speed control link to the variable

speed torque bracket assembly.

I.

Push

the

clutch-brake

pedal

backward

by

hand as far as it will go using light pressure.

Hold it in this position as you thread the speed

control link in or out of the ferrule until it lines

up with the pin on the variable speed torque

bracket assembly.

J.

Secure speed control link to variable speed

torque bracket assembly with flat washer and

cotter pin.

11