Specifications—units with electric heater – Bryant 517G User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

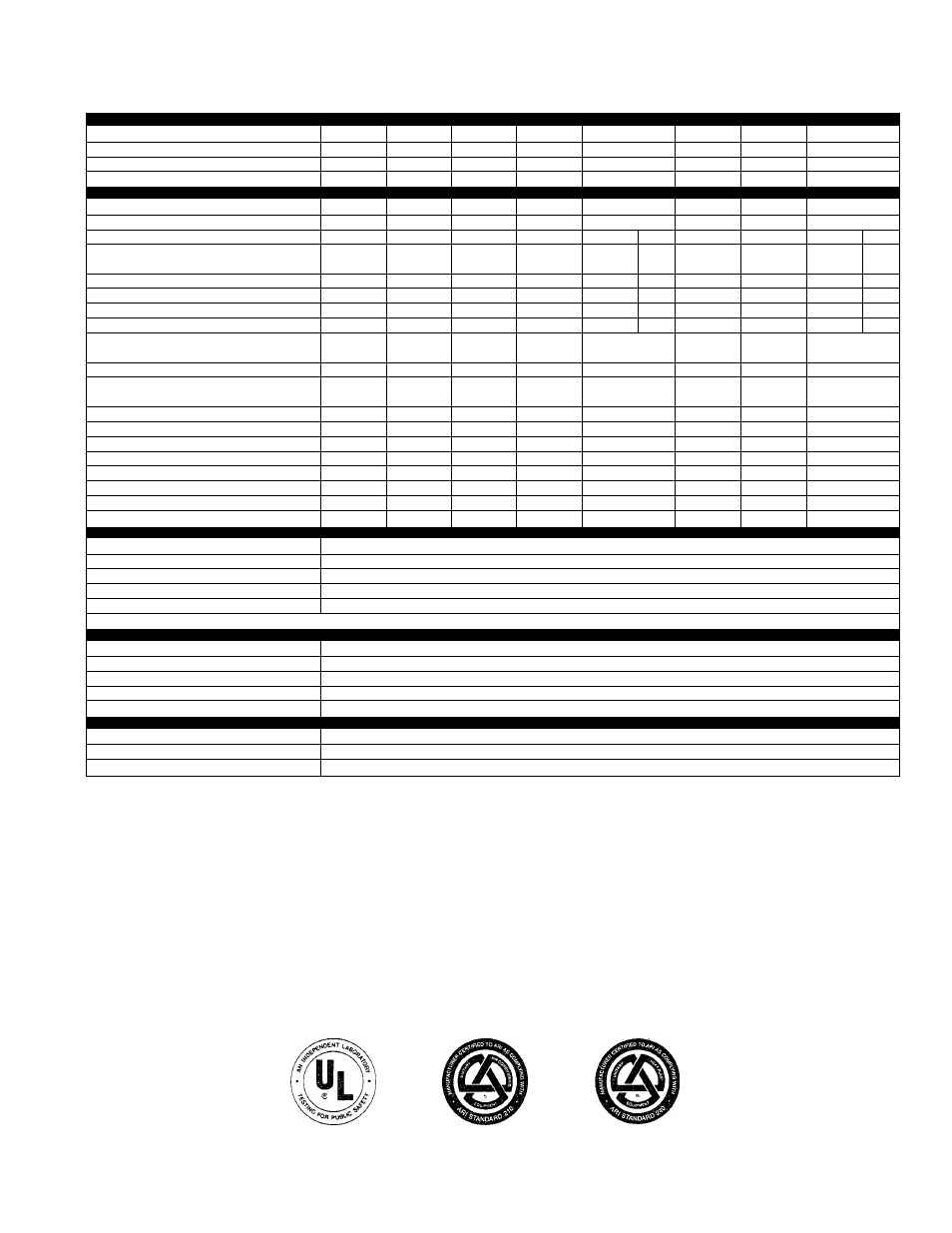

SPECIFICATIONS—UNITS WITH ELECTRIC HEATER

MODEL

5170

SIZE

N042075

N042010

P042010

N042012

N042015

P042015

P042018

N042020

RATINGS & PERFORMANCE

Nominal Capacity (Btuh)^

42,000

42,000

42,000

42,000

42,000

42,000

42,000

42,000

Nominal Airflow (FP /Min)t

1400

1400

1400

1400

1400

1400

1400

1400

Electric Heating Output (KW)t

7.5

10.0

10.0

12.0

15.0

15.0

18.0

20.0

Electric Heating Capacity (MBtuh)t

19.2/23.5

25.6/31.3

25.6/31.3

30.8/37.6

38.5/47.0

38.5/47.0

46.1/56.4

51.3/62.7

ELECTRICAL

Unit Volts—Phase (60 Hz)

208/230-1

208/230-1

208/230-3

208/230-1

208/230-1

208/230-3

208/230-3

208/230-1

Operating Voltage Range

187-253

187-253

187-253

187-253

187-253

187-253

187-253

187-253

Internal Circuit Protections^

None

None iCBft

None

Fuses

Fuses

CBtr

None

None

Fuses

CBtt

Single-Circuit Operation

Rated Load Amps

30.8/33.8

39.8/43.8

24.6/26.8

47.2/51.8

57.8/63.8

_

35.0/38.5

41.4/45.4

75.8/83.8

_

Minimum Ampacity for Wire Sizing

40.8/44.5

52/57

33/35.75

61.25/67

74.5/82

—

46/50.4

54/59

97/107

—

Minimum Wire SizeH

8/8

6/6

8/8

6/4

6/4

_

6/6

6/6

3/2

—

Maximum Wire Length (Ft)B

95/96

115/115

146/148

97/154

79/125

—

160/161

136/137

120/152

—

Maximum Fuse Size (Amps)

45/45

60/60

35/40

70/70

80/90

—

50/60

60/60

100/110

—

Dual-Circuit Operation

Rated Load Amps LI & L2

32.7/35.8

39.8/43.8

_

_

39.8/43.8

L 3 & L 4

—

—

14.5/16

18/20

_

-

36/40

Minimum Ampacity for Wire Sizing

LI &L2

43.1/47

52/57

_

_

52/57

L 3 & L 4

—

—

18/20

22.5/25

—

—

45/50

Minimum Wire SizeH LI & L2

—

—

—

8/6

6/6

—

—

6/6

L 3 & L 4

_

_

_

12/12

10/10

—

—

8/6

Maximum Wire Length (Ft)H L1 & L2

_

—

—

89/141

115/115

—

—

115/115

L 3 & L 4

—

80/80

102/102

—

—

81/126

Maximum Fuse Size (Amps) LI & L2

_

—

—

45/50

60/60

—

60/60

L 3 & L 4

—

—

20/20

25/25

—

—

45/50

Control Transformer—24V (VA)

60

60

60

60

60

60

60

60

INDOOR COIL

Rows & Fins Per Inch

3 & 1 3

Height

X

Width (In.)

3 2 . 5 x 1 9 . 4

Face Area (Sg Ft)

4.4

R-22 Refrigerant Metering Device

Check-Flo-Rater

Piston ID Number

76

Condensate Drain Connection (Pri-Sec)

3/4 MPT-3/4 FPT

INDOOR BLOWER & MOTOR

Wheel Diameter x Width (In.)

1 0 x 9

Filter Size—Cleanable (In.)

20

X

21

X

1

Blower Motor HP

1/2

Blower Motor Speeds

&

Type

3

&

DD(PSC)

Rated Load Amps

3.8

OPTIONAL EQUIPMENT (P/N’S)

Liguid-Tube Swivel Ell (3/8)TT

P651-1066

Vapor-Tube Swivel Ell (3/4)tt

P651-1068

Single-Circuit Kit^*

- 1 - 1 - 1

301820-4001

1 - 1 - 1

301820-4001

*See condensing unit or heat pump outdoor section PDS for cooling and/or heating capacity ratings with 517G Fan Coils.

tSee air delivery table in this PDS.

JKW values shown are nominal rated heater outputs at 240V and do not Include blower motor heat. Capacity values shown are calculated using KW

outputs at 208V/230V.

♦♦Single-phase 10-, 15-, or 20-KW electric heaters have the internal circuit protection options shown. Single-phase 12-, 15-, or 20-KW heaters are

wired for dual-circuit operation. The optionai single-circuit kit may be field-installed In units with a 12-, 15-, or 20-KW single-phase fused heater for

single-circuit operation.

ttCB = circuit breakers

ttUsed for right-angle refrigerant connections to the coil.

♦♦♦A 60-VA control transformer for units without factory-supplied heaters is supplied with the accessory electric heat package or control package. The

control package must be field-installed when a heater is not being used.

HWire sizes and lengths are based on copper conductor at 86 ° F (30 ° C) ambient temperature and ampacity shown in table. Insulation must be 90 ° C

on conductor used between the disconnect switch and the heater and at least 75 °C on the conductor used between the disconnect and the serv

ice panel. If other than copper conductor Is used, or if ambient temperature is above 86 ° F, determine wire size from ampacity shown and the Na

tional Electrical Code. Wire lengths shown are measured one way along the wire path between the disconnect and service panel for minimum 2%

voltage drop.

CERTIFICATION APPLIES ONLY WHEN

USED WITH PROPER COMPONENTS

AS USTED WITH ARI

SSC-67