Figure 7 - drip leg location, Pilot – Bryant 452W User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

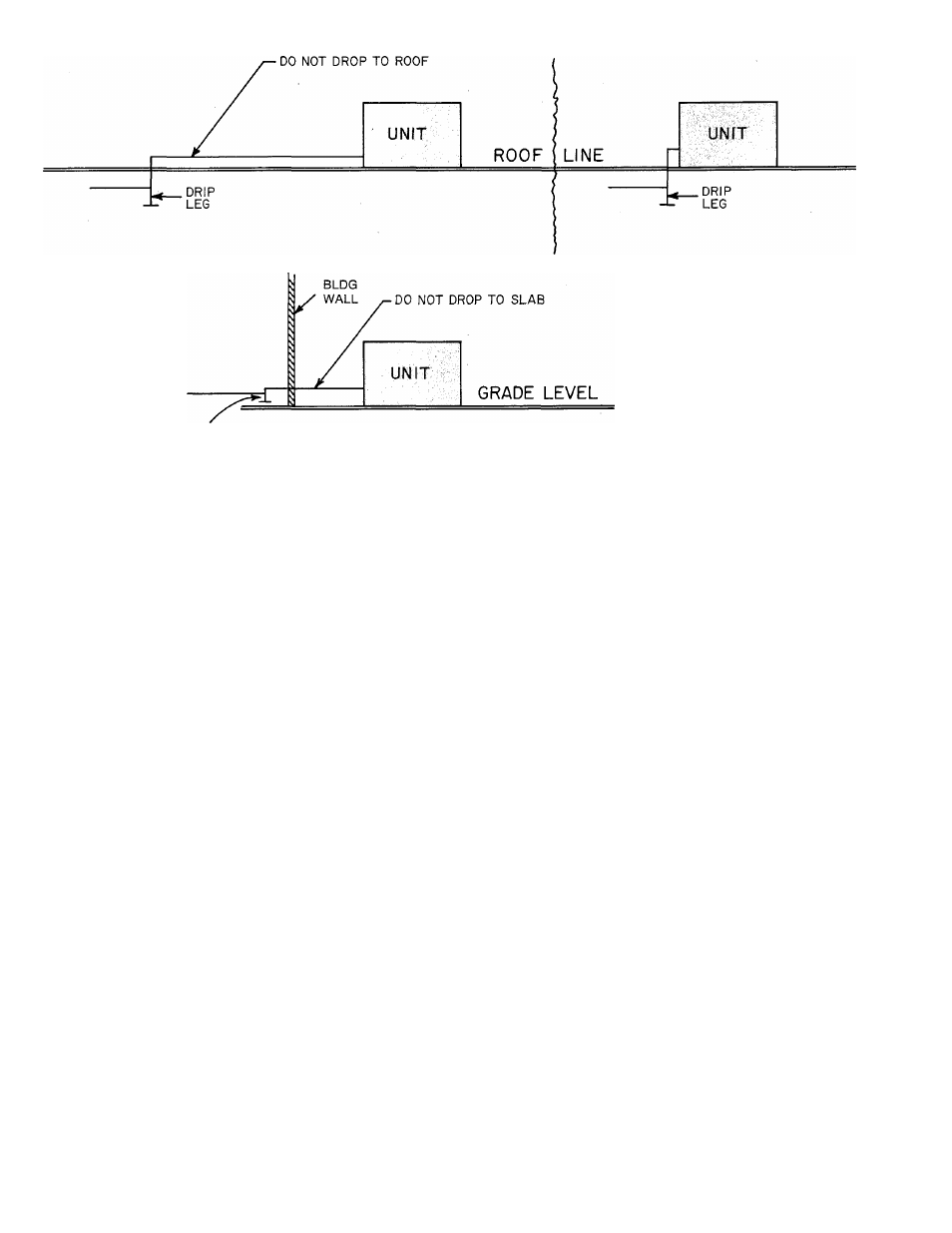

DRIP LEG

WITHIN STRUCTURE

A70676

Figure 7 - Drip Leg Location

on the right side. Install a drip leg trap in the gas sup

ply riser leading to the unit.

The following are pertinent recommendations:

1. Avoid low spots in long runs of horizontal pipe. It

is best to grade all pipe 1/4 inch for every 15 feet

to prevent traps. All horizontal runs should grade

downward to risers. Use risers to connect to unit

and to meter.

2. Install drip leg in riser leading to unit. Drip leg

will serve as trap for dirt and condensate. Install

drip legs where condensate will not freeze. See

Figure 7 for drip leg location.

3. Install wrench-type shutoff valve in gas supply

line within sight of, and convenient to, unit.

4. Place ground joint union close to unit between

gas controls manifold and wrench-type shutoff

valve.

5. Support all piping with appropriate hangers.

Maximum distance between hangers should be

10 feet.

6. Joint compound (pipe dope) which is resistant to

action of liquefied petroleum gases should be ap

plied sparingly and only to male threads of

joints.

7. After all gas pipe connections are made, purge

lines and check for leakage. Turn off power sup

ply to unit when purging lines to prevent glow

coil in reignition pilot from being energized. Use

a soap-and-water solution for leak-checking.

WARNING:

Never

use

maiclies.

candles,

or

other

.sources ol' ignition to check for gas leakage.

Pilot

Both natural gas and propane gas units are equipped

with an automatic reignition pilot. The pilot will light

automatically when supplied with gas and is elec

trically energized.

Light the pilot using the procedure outlined on the

lighting instruction plate attached to the generator.

However, when lighting the pilot for the first time,

perform the following additional steps:

1. If supply line was not purged prior to connecting

unit, it will be full of air. Because venting air

through small pilot port is a lengthy process, it is

recommended that pilot supply line be discon

nected at pilot shutoff valve and supply line be

allowed to purge until odor of gas is detected.

WARNING: Never purge gas lines inii) the com

bustion chamber.

Immediately upon detection of gas odor, recon

nect pilot supply tube. Allow 5 minutes to elapse

and light pilot in accordance with instructions on

lighting plate.

2. Pilot flame should be soft blue in color and of

sufficient length to provide good impingement on

unimetal of Bryant pilot. Flame should, extend

upward between carryover ports of two adjacent

burners.

3. If pilot flame does not have appearance

described above, adjust it by means of manual

pilot shutoff valve.

a. The valve is equipped with an adjustable

screw. Turn handle to full open position, and

— 6