Table vi—manifold pressure (inches w.c.), Vii. adjusting gas input, Viii. balancing the system – Bryant 452W User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

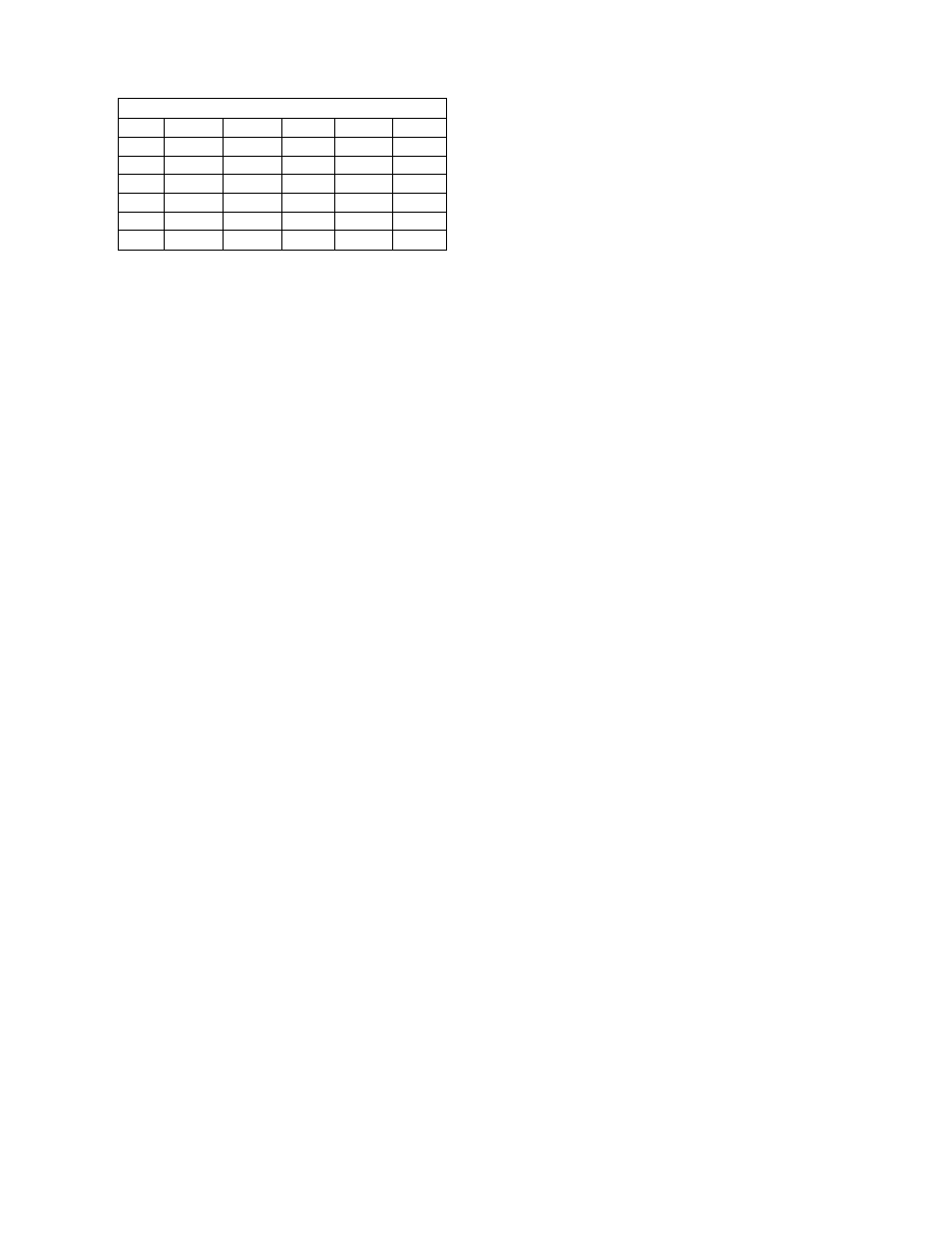

TABLE VI—Manifold Pressure

(Inches

W.C.)

0)

3

'

03

>

OQ

Specific Gravity

0.59

0.61

0.63

0.65

0.67

900

3.9”

4.0”

4.1”

4.2”

4.3”

950

3.5”

3.6”

3.7”

3.8”

3.9”

1000

3.1”

3.2”

3.3”

3.4”

3.5”

1025

3.0”

3.1”

3.2”

3.3”

3.4”

1050

2.8”

2.9”

3.0”

3.1”

3.2”

1100

2.6”

2.7”

2.8”

2.9”

3.0”

For manifold pressures exceeding 3.0 inches ±¡.3 inches, consult

your Bryant Distributor.

heater circuit that permits operation of the unit at

outdoor ambient temperatures down to -30°F. The

pump heater circuit consists of a hydraulic pump

heater (11A2) and a pump heater relay (2B).

The pump heater is connected in series with the nor

mally closed contacts of the pump heater relay.

Current flows through the heater only when there is

no demand for cooling hy the thermostat. When the

thermostat calls for cooling, the pump heater relay

winding is energized and opens the normally closed

contacts of the pump heater relay and removes the

power supply voltage from the pump heater.

VII. ADJUSTING GAS INPUT

The gas input must be checked and adjusted if

necessary to agree with that shown on the rating plate

of the unit (246,000 Btuh). The burners are equipped

with fixed orifices drilled as follows; Natural gas No.

36 drill; Propane gas No. 52 drill.

The natm-al gas units are equipped with adjustable

gas pressure regulators set at factory for 3.0-inches

w.c. manifold pressure. The propane gas units are not

equipped with a pressure regulator.

Check natural gas units by one of the following

methods:

1. Measxrre gas at meter. Be sure all other gas ap

pliances are turned off. Increase or decrease in

put to burners by adjustment of gas pressure

regulator.

2. Set manifold pressure according to Table VI for

Btu value and specific gravity of gas to be sup

plied to unit. Connect manometer to 1/8-inch

pressure tap on manifold and, with unit in

operation, set correct pressure by adjustment of

gas pressure regulator.

Example: Natrual Gas

1025 Btu

0.63 Specific Gravity

1. From Table VI, manifold pressure is 3.2 inches

w.c.

2. With manometer connected to manifold, set

pressure at 3.2 inches by adjusting gas pressure

regulator.

Check propane gas units as follows:

The burner orifices are sized for rated input with a

manifold pressure of 11.0 inches w.c. Connect

manometer to 1/8-inch pressure tap on unit manifold

and adjust regulator at supply tank to provide a

manifold pressure of 11.0 inches w.c.

CAUTION: The unit may be run for short periods

with

the

panel

removed.

Proloiif;ed

operatioti

with

panels removed sliould not he attempted.

VIII. BALANCING THE SYSTEM

After the unit is operating and the input has been

measured and adjusted to agree with the rating plate

requirements, balance the system.

Any approved method of checking the a:irflow over the

water coil may be utilized. Reference is made to the

Bryant Service Manual on Gas Air Conditioning for a

review of standard methods. Do not purge non

condensibles or check solution level.

— 10