Note, Hydrostatic transmission cooling, Warning – Bolens 138-784-401 User Manual

Page 16: Trouble shooting, Crankcase oil, Fuel filter, Wheel alignment, Figure 19, Trouble shooting charts -22, Maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2. Unscrew the two screws holding the access cover

located in front of the seat.

3. Check the oil level in the reservoir/expansion tank.

See figure 17.

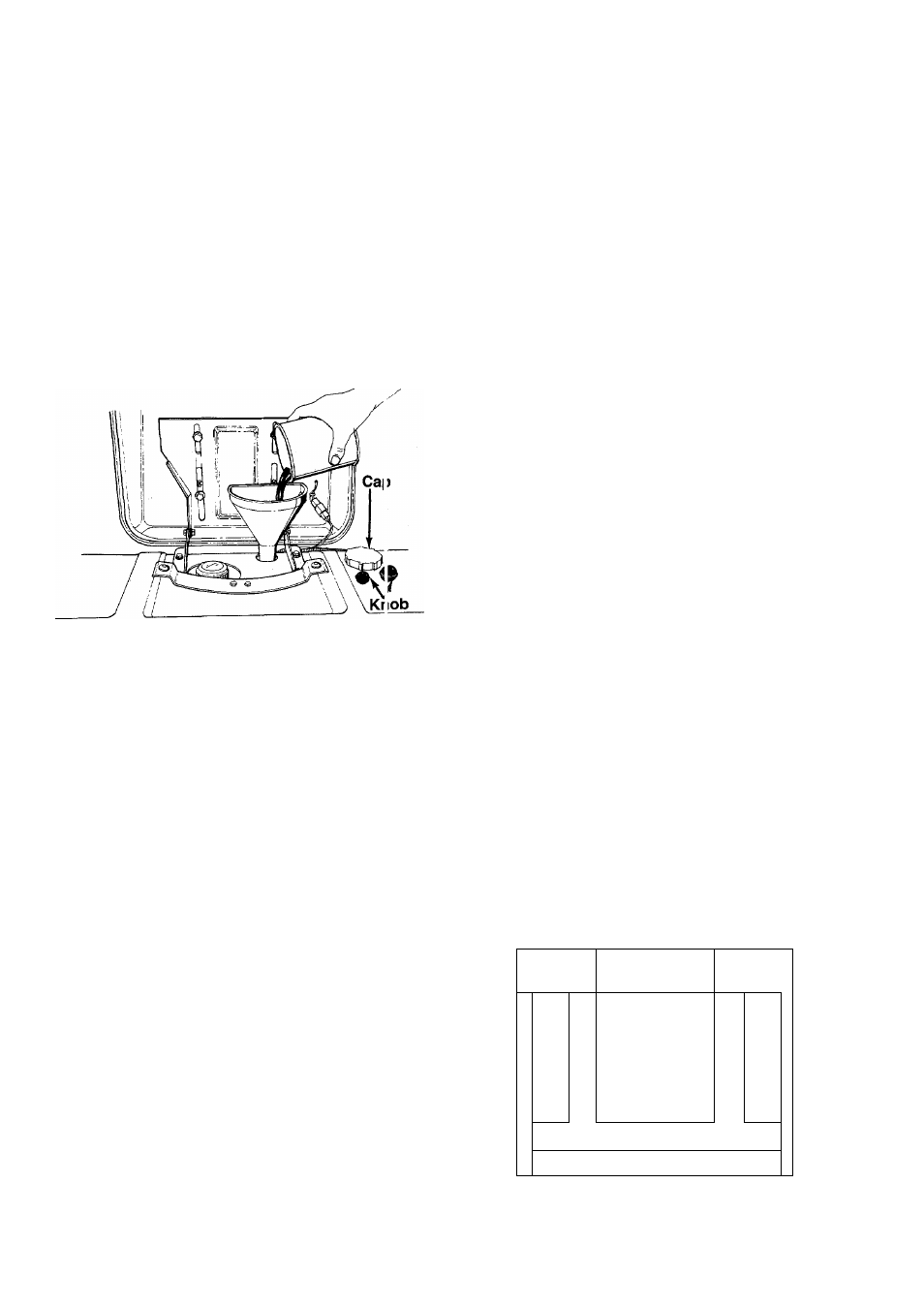

If it is necessary to add oil, unscrew the cap on the

reservoir/expansion tank and add oil through the

hole with a funnel. Do not overfill. See figure 18.

Reassemble parts.

If frequent additions are required, locate the leak and

correct. Inadequate supply of fluid may result n per

manent internal damage.

4.

5.

FIGURE 18.

If contaminate is observed on the reservoir/expansion

tank screen, poor maintenance is indicated. Rrsmove

the reservoir/expansion tank, wash clean, dr/ and

reinstall. If the screen is pierced, the reservoir/«expan

sion tank should be replaced.

NOTE

The threads on the reservoir/expansion

tank are left hand thread.

If the natural color of the transmission fluid has

changed, black or milky, overheating and/or wate r con

taminate is indicated. The fluid should be drained and

replaced with new transmission fluid.

To drain the hydrostatic transmission, remové tf e hex

plug on the bottom of the hydrostatic transmission.

To fill the hydrostatic transmission, remove th«s vent

plug located next to reservoir/expansion tank ts pre

vent an air lock. Replace vent plug.

Hydrostatic Transmission Cooling

The hydrostatic transmission is cooled by the oil, fan

and fins. Normal operating temperature is 180" F. If

the hydrostatic transmission runs hot, check to see if

the fan is in operating condition, the oil level is correct

and the fins are clean.

NOTE

DO NOT use high pressure water spray

or steam to clean the hydrostatic trans

mission.

MAINTENANCE

Ar-

WARNING

Disconnect the spark plug wire and

ground

against

the

engine

before

performing any adjustments, repairs

or maintenance.

TROUBLE SHOOTING

Refer to the chart on pages 21 and 22 for trouble

shooting engine problems.

CRANKCASE OIL

Check the oil level in the crankcase before each use

of the machine and after every two hours of operation.

Oil level should be maintained as instructed in the

separate engine manual.

After the first two hours of operating a new engine, drain

the oil from the crankcase while engine is still hot and

refill crankcase with new oil; thereafter change the oil

after every 25 hours of operation. Refer to the engine

manual.

FUEL FILTER

Your unit is equipped with a replaceable in-line fuel

filter. Replace filter whenever contamination or

discoloration is noticed. Order replacement filter

through your authorized engine service dealer.

WHEEL ALIGNMENT

The front wheels should toe-in approximately 1/8".

Measure the distances A and B on the front wheels.

See figure 19.

■^NOTE

Dimension B should be approximately

1/8 inch less than dimension A.

A

r

IS

Front

%

(1/8"

le^ than A)

FIGURE 19.

16