Bryant Model 516 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Limitations and Recommendations

1. The duct heaters should never be installed

from the bottom or the top of the duct - only

from the sides of the duct. The heaters must

always be installed on the discharge side of

the Fan Coil.

2. Only one duct heater may be used in any

one duct. If the capacity required exceeds the

output of one duct heater, select the total

number of heaters and proportion them in

separate runouts or separate ducts from the

plenum.

3. Install the duct heater at least 18 inches

away from any canvas duct connector. If the

heater must be located closer, replace the

canvas connector with an asbestos connector.

4 . The control enclosures of the duct heaters

must be completely accessible and so located

as to provide ventilation at all times.

5. The air duct should be installed in ac -

cordance with the standards of the National

Board of Fire Underwriters for the Instal

lation of Air Conditioning and Ventilating

Systems of other than Resident Type (pamphlet

no. 90A), and Resident-Type Warm Air Heat

ing and Air Conditioning Systems (pamphlet

no. 90B).

6. Each duct heater should be provided with

a fan relay. The heater and fan motor are to

be wired so that the duct heater cannot oper

ate unless the fan is on. Always hook the fan

interlock to the high-voltage side of the

system. Never use a fan delay with the

electric duct heater.

7.

The coil of the secondary contactor

(general-purpose, continuous duty rated at

6000 cycles) must be wired in series with the

manual reset limit control (TMR).

NOTE; Observe at least one complete heating

cycle before leaving the installation.

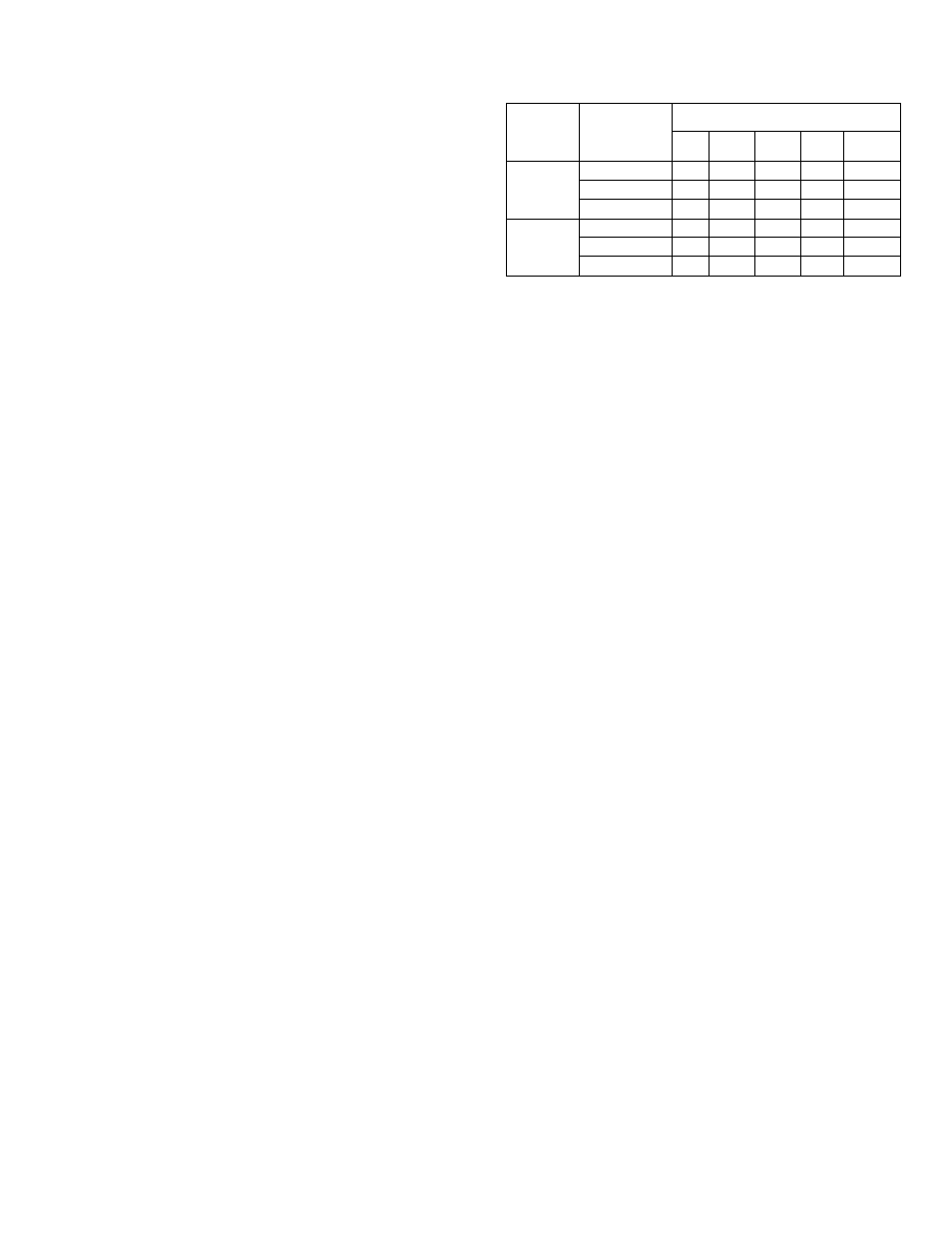

Table II - Air Delivery at Indicated Static Pressure

(Dry Coil, Less Filter)

Model

Evaporator

Motor

Speed Tap

CFM

*0.0

*0.1

*0.2

*0.3

*0.4

18-516

High

930

920

905

890

860

Medium

705

700

690

675

650

Low

605

600

590

580

550

24-516

High

955

940

915

880

830

Medium

695

690

680

670

680

Low

615

605

600

580

555

* Static pressure - inches w.c.

Electrical Connections

Make all electrical connections in accordance

with the National Electric Code and any local

codes or ordinances that may apply.

Provide power supply (or supplies; 11- throu^

14.4-KW heaters will have two power sup

plies) for the heating capacity of the unit

being installed in accordance with Table I -

Ratings and Capacities. Power supply con

nections are made at the high-voltage termi

nals with wire suitable for at least 90° C

(194°F). It is good practice to ground casing

parts and to check factory wiring connections,

to be sure none were loosened in transit or

installation. Refer to Figures 5, 6, and 7 for

field wiring diagrams.

Thermostat Connection

The electric duct heater and Model 516 Fan

Coil Unit are designed for use with a 24-V

heat-cool thermostat, Bryant Model 883 .

Connect the thermostat and the low-voltage

terminal block on the side of the Fan Coil in

accordance with field wiring diagrams -

Figures 5,

6, and 7. Set the thermostat

heating anticipator at 0.8 amps .

- 3 -

39516D3