Carburetor adjustments (see figure 19) – MTD 241-640A User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A

CAUTION

Disconnect high tension wire at spark

plug to prevent accidental starting

of engine. Unscrew oil drain plug

located on side at bottom of engine

See figure 17.

NOTE

Always tip engine towards oil drain

hole. Be sure oil drains completely.

Replace oil drain plug and refill with oil as directed

on page 6 or engine nameplate.

2. Check oil every five (5) operating hours or each

time equipment is used.

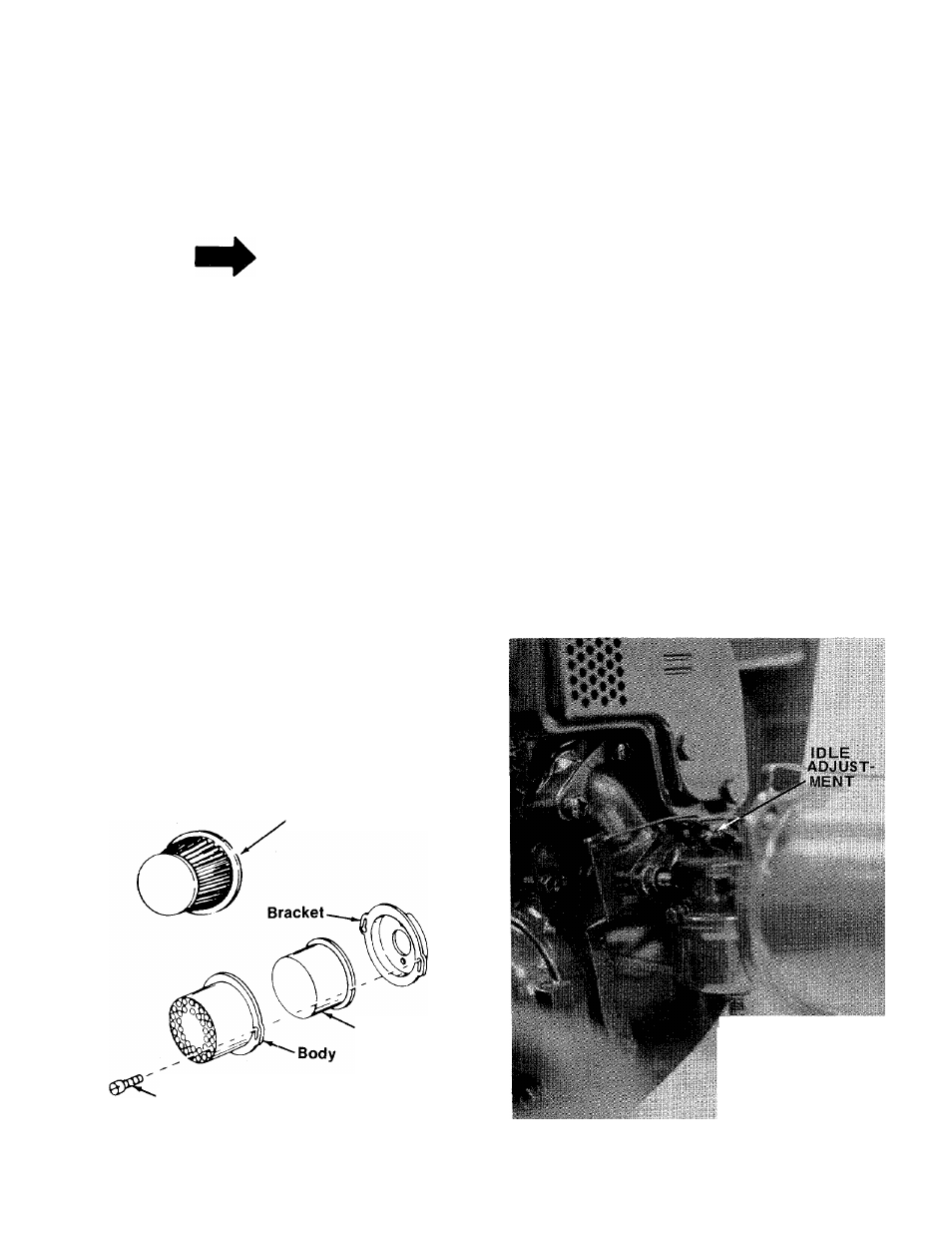

CARBURETOR ADJUSTMENTS (See figure 19)

Do not make unnecessary adjustment. Factory

settings are correct for most application. If

adjustments are needed, proceed as follows:

1. Close power adjusting needle (figure 19)

I

turning to right (clockwise). Close finger tigh.

only. Forcing will cause damage.

2. Open one turn (counterclockwise).

3.

Close idle adjusting needle (figure 19) by turning

to right (clockwise). Close finger tight only.

Forcing will cause damage.

4. Open one and one-half (1-1/2) turns (counter

clockwise).

5. Start engine. Follow starting instructions page 6.

6.

With throttle open (carburetory control at RUN

or FAST position) adjust power adjusting needle

one-eighth (1/8) turn at a time forward to back

ward until engine runs smoothly. If engine tends

to stall under load enrich mixture slightly

(counterclockwise).

3. Cleaning engine—This is an aircooled engine which

operates most efficiently when the cooling fins

are clean.

Clean cylinder fins and underside of tank or housing

thoroughly of all accumulated grass and debris.

4. Air Cleaner. (See figure 18).

Paper Type Element. Remove every 10 hours or

oftener if under dusty conditions. Tap to remove

loose dirt and/or blow from inside out with low

pressure air. Replace if torn or perforated or

when plugged to maintain proper carburetor

setting (50 hours). DO NOT WASH IN ANY

LIQUID A

nd

do

notoil

.

Paper Element

Element

-Attaching Screw

7.

Hold throttle lever closed or move carburetor

.control to IDLE or SLOW position and adjust

idle adjusting needle until engine runs smoothly

proceeding in step six (6) above.

8.

Allow several seconds between each adjustment

when performing either step six (6) or seven (7)

to allow engine to react to new setting.

pi)WER ADJUSTING

NEEDLE

FIGURE 18

FIGURE 19

10