D. chain tension – Poulan PRO 305 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

•

Your saw is equ^ped with a Reduced-Kick

back Bar and a Low-^ckback Chain.

•

Always use the Reduced-Backback Guide

Bar and Low-Kickback Chain specified for

your chain saw model when replacing these

parts. See the “Specifications^ section.

e. ATTACHING THE BAR AND CHAIN

A

WARNING

Do not start the engine without the guide bar and

chain completely assembled. Otherwise, the

clutch can come off and serious injury can result.

I CAUnON: I Wear protective gloves when han

dling or operating your saw. The chain is sharp

and can cut you even when it is not moving!

1. Removetheharclampnuts, bar clamp, and ]}}astic

spacer if you have not already done so. Discaard

plastic spacer.

2. Turn the adjusting screw (Fig^ lO) counter

clockwise to move the adjusting pin almost as far as

it will go to the rear.

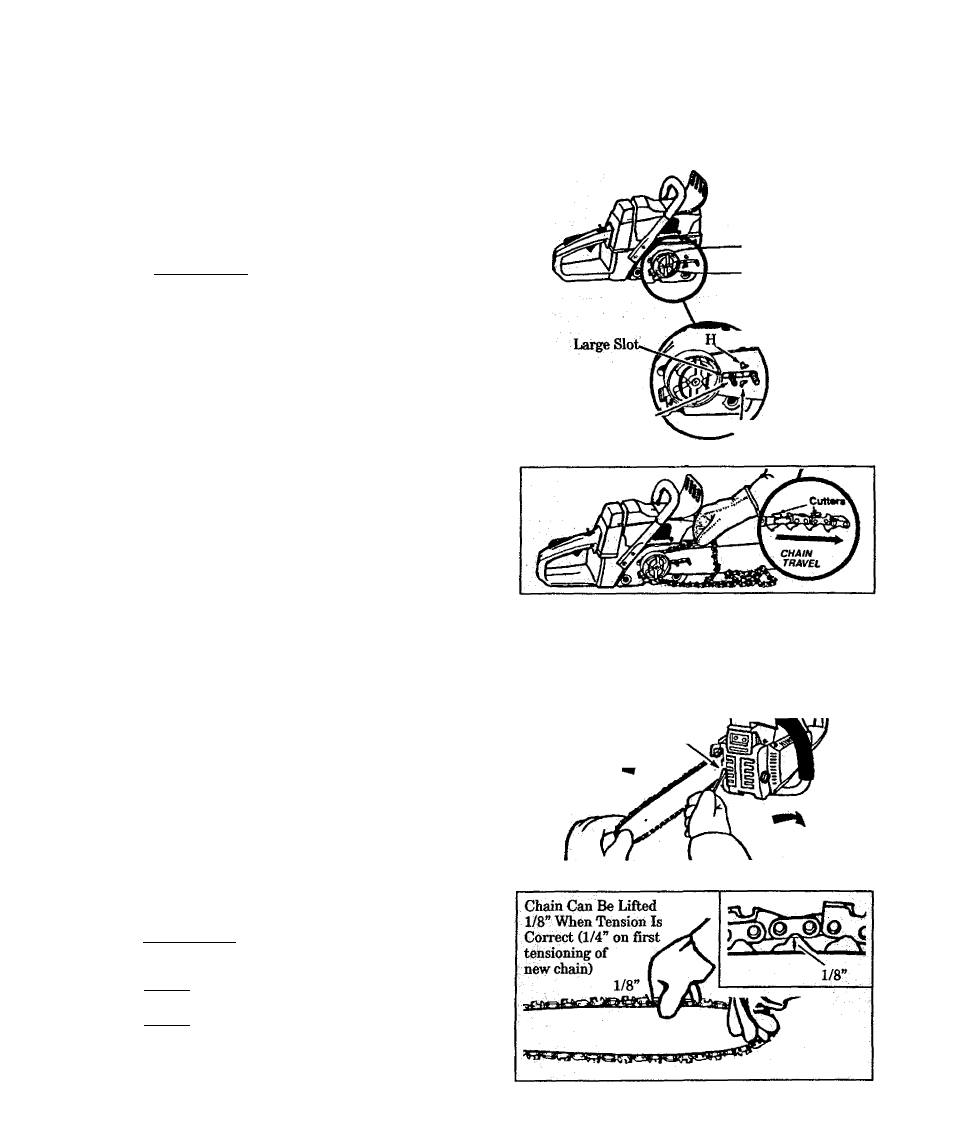

3. Mount the guide bar imth the slotted end over the

moimting studs. Figi^ 8 . Position the adjusting

pin in the adjusting pin hole. Figure 8.

4. Hold the chain with the cutters facing as shown in

Figure 9 (inset).

5. Place the chain over and behind the clutch drum

and onto the sprocket. Figure 9 . Fit the bottom of

the drive links between the teeth in the sprocket.

6. Slide the ^de bar towaid the rear of the saw as far

as possible.

7. Start at the top of the bar and fit chain drive links

into the groove around the guide bar. Figure 9.

8. Turn the adjusting pin clockwise until the chain is

snug in the guide bar groove. Figure 10.

D. CHAIN TENSION

• Ck>rrect Chaiu Tensipu is very im^rtant—

- A loose chain will wear thè bar and itself

- A loose chain can jtunp off the bar while you are

cutting

- A tight chain can break or damage the saw and/

orbar.

•

The chain stretches during use, especi^y

when new. Check tension periodically as follows:

- each time the saw is used;

- more frequently when the chain is nev^

- as the chain warms up to normal operating

temperature.

• Chain tension is correct when the chain:

~ can be lifted about 1/8" from the Guide Bar at a

point near the middle of the bar and

will move freely around the bar.

installing a new chain, allowthe chain to

be lifted 1/4" from the bar. Thereafter, follow the

instructions as indicated.

• Chain tensioning procedure:

I WARNING: i Always wear ^oves when handl-

ihg the chain. The chain is shaxm and can cut

you even when it is not moving!

NOTE; The bar clamp nuts must be no more than

finger tight to tension the chain correctly.

NÓTE; Hold tip of guide bar up through step 4.

1. yft up the tip of the guide bar and turn the adjust

ing screw clockwise until the chain does not sag be

neath the guide bar. Figúrelo.

2. Check the tension by lifting the chain from the

guide bar at the center of the bar. Figure 11.

9. Hold the guide bar against the saw frame and in

stall the bar clamp,

10, Replace the bar clamp nuts and tighten finger tight

only. Tighten bar clamp nuts after chain is

tensioned.

IL Proceed to the “Chain Tension” section.

ole Above Slot

Bar

Mounting

Studs

Adjusting Pin Hole

Figures

Figure 9

3. Cohtmue adjusting the adjusting Screw until the

tension is correct.

4. Lift up the tip of the guide bar and tighten the bar

clamp nuts with the scrench.

6. Rechecfc chain tension. Figure 11.

Turn To

Increase

Chain

Tension

Adjusting Screw

Turn To

Decrease

Chain

Tension

Figure 10

Figure 11

-8-