Guide bar maintenance, B. spark arrestor, Figúrese – Poulan PRO 305 User Manual

Page 17: Qxid 1

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A WARNING

llie, Pepth Gauge Tool is reouired to insure prop

er d^jptli gauge. Filing the depth gauge too deep

wRl increase the chance of nckhack which can

rijsiilt in serious injury.

_______________

b.

CHAIN REPLACEMENT

1. ) Use only the Low-Kickback replace

ment chain speciRed for your saw in

the **Specifications** section.

2. ) Replace the chain when cutters or

links break.

3. ) Scie a quailed sendee dealer to re-

S

lace or sharpen your chain.

Iways have a worn sprocket r^laced

by a qualified service dealer when in

stalling a new chain to avoid excessive

wear to the chain.

2. GUIDE BAR MAINTENANCE

• Conditions which can require ^zide bar

maintenance:

— saw cuts to one side.

—: Saw has to be forced throu^ a cut.

-- inmlequate supply of oil to bar and

chain.

• Check the condition of the ^lide bar each

time the chain is sharj^ned. A worn guide

bar wdl damage the chain and m8ike cutting

more difficult.

• Replace the guide bar when:

— the inside groove of guide bar rails is worn.

— the guide bar is bent or cracked. See Fig

ure 35.

• Use only the replacement Reduced-Kick

back Guide Bar specified for your saw in

the “Specification’* section.

a. Remove the guide bar to service.

b. Clean the oil holes at least once after eveiy

five hours of operation.

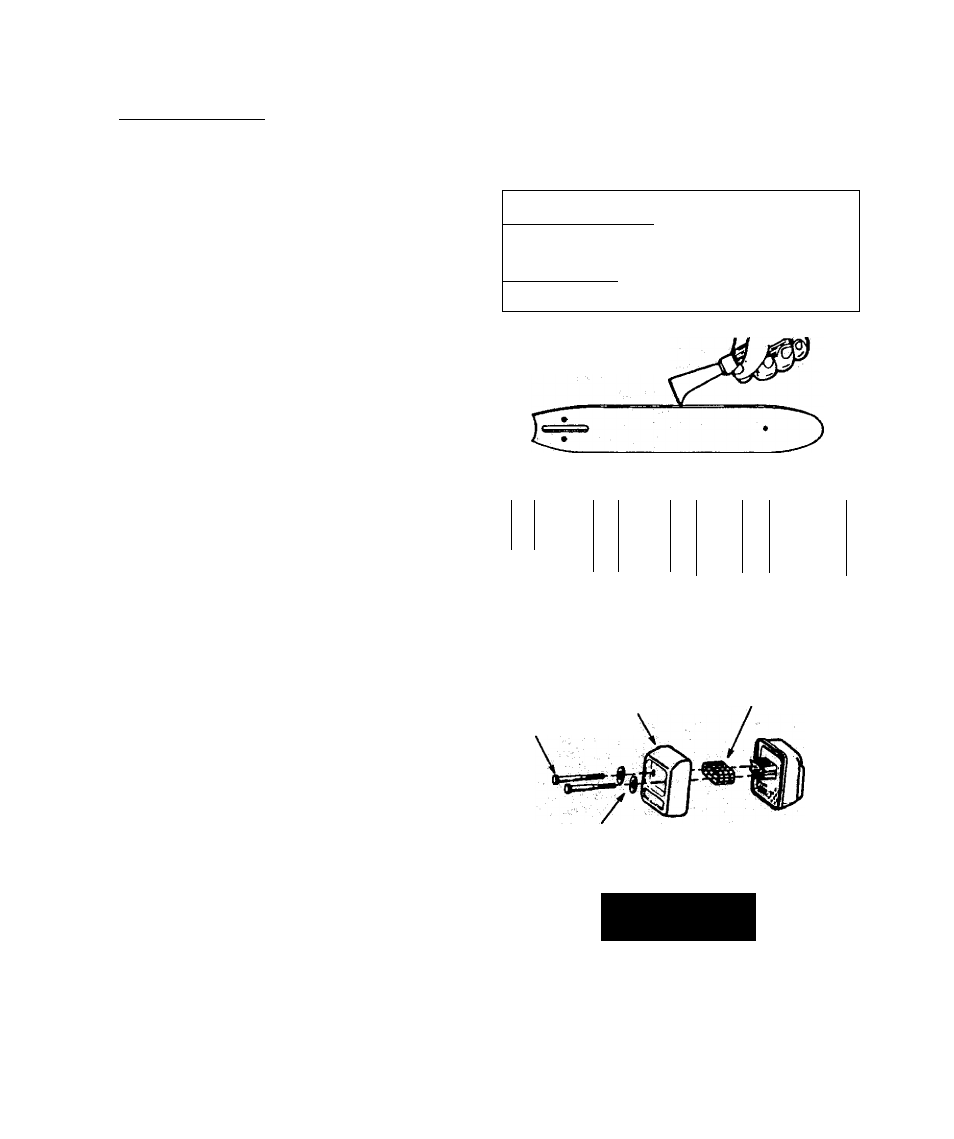

c. Removal ^wdust from the gmde bar groove

periodically with a putty knife or a wire. Fig

ure 34,

d. Reniove burrs by filing the side edges of the

guide biiir grooves square with a flat file. Fig

ure 35 .

e. Restore square ed^s to an uneven rail top be

filing with a flat file. Figure 35 ._________

HookAn^e

L

--------

.025-

Too Much Squared

Hook Angje^^ Off Comer

/—C

jn

i o _ o

r

Rounded / 1

o.n«r

(QXiD 1

Right Way

Wrong Way

Figure 33

Remove Sawdi^t

From Guide Bar Groove

Figure 34

¥

R

1

¥

i

Correct

Guide Bar Worn Grooves

Groove

File Edges

Square

Figure 35

B. SPARK ARRESTOR

__• Carbon deposits build up on the spark arres-

toras the saw is used and must be removed to avoid

creating a fire hazard or causing engine damage.

• Replace the spark arrestor if breaks occur.

• ^ep the spark arrestor clean at 8Á1 times.

Clean:

—as required.

—at least once for each 25-30

hooirisf of operation.

Items required: wire brush, 3/8” wrench

1, Disconnect the spark plug wire.

the muffler cover screws and washers.

Remove the muffler cover. Figure 36.

3 iftemove the spark arrestor screen. Figure 36.

4. Clean the screen with a wire brush or replace if

breaks are found.

5. Reassemble parts.

Muffler

Cover

Screws

Muffler

Cover

Spark Arrestor Screen

Washers

Figúrese

HtLAl)

SPECIAL SAFETY SECTION

FREQUKN’M.Y

- 1 7 -