Lubrication, Maintenance, Lubrication maintenance – MTD 406 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

LUBRICATION

A

WARNING: Always stop engine and dis

connect spark plug wire before cleaning,

lubricating or doing any kind of v/ork on

tiiler.

Chain Cases

—The chain cases are pre-lu jricated

and sealed at the factory. They require no < becking

unless the chain cases are disassembled. Tci fill with

grease, lay the left half of the chain case on its side.

Add 12 ounces of plastilube #0 grease to the tine

chain case or 10 ounces to the wheel chain case.

Assemble the right half to it. This grease can be

obtained through your nearest authorized dealer.

Order part number 737-0133 (14 oz. tube).

Wheels

—Lubricate the wheel bearings with a light oil

after each fifteen hours of operation.

Ciutch Controls

—Lubricate the pivot points on the

clutch levers and the cables at least once a season

with light oil. The controls must operate freely in both

directions.

Pivot Points

—Lubricate all pivot points and linkages

at least once a season with light oil.

MAINTENANCE

A

WARNING: Disconnect the spark piug

wire and ground it against the engine

before performing any repairs o' mainte

nance.

IMPORTANT:

If for any reason the tines are removed

from the tiller, be certain the tines are reassrsmbled so

that the sharp edge of the tines enter the soil first.

Refer to item number one under “Operation. ’

TROUBLE SHOOTING

Refer to page 15 of this manual for troubk shooting

information.

ENGINE

Refer to the separate engine manual for all engine

maintenance instructions.

Maintain

engine oil

as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service

air cieaner

every 25 hours under n Drmal con

ditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaners should be ser

viced. To service the air cleaner, refer to the separate

engine manual packed with your unit.

The

spark plug

should be cleaned and the gap reset

once a season. Spark plug replacement is recom

mended at the start of each tilling season; check

engine manual for correct plug type and gap specifi

cations.

CLEANING THE TINE AREA

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if washed immedi

ately instead of after if dries.

TIRES

Recommended operating tire pressure is approxi

mately 12 p.s.i. (check sidewall of tire for tire manu

facturer’s recommended pressure). Maximum tire

pressure under any circumstances is 30 p.s.i. Equal

tire pressure should be maintained on both tires.

When installing a tire to the rim, be certain rim is

clean and free of rust. Lubricate both the tire and rim

generously. Never inflate to over 30 p.s.i. to seat

beads.

A

WARNING: Excessive pressure (over 30

p.s.i.) when seating beads may cause

tire/rim assembiy to burst with force suf

ficient to cause serious injury.

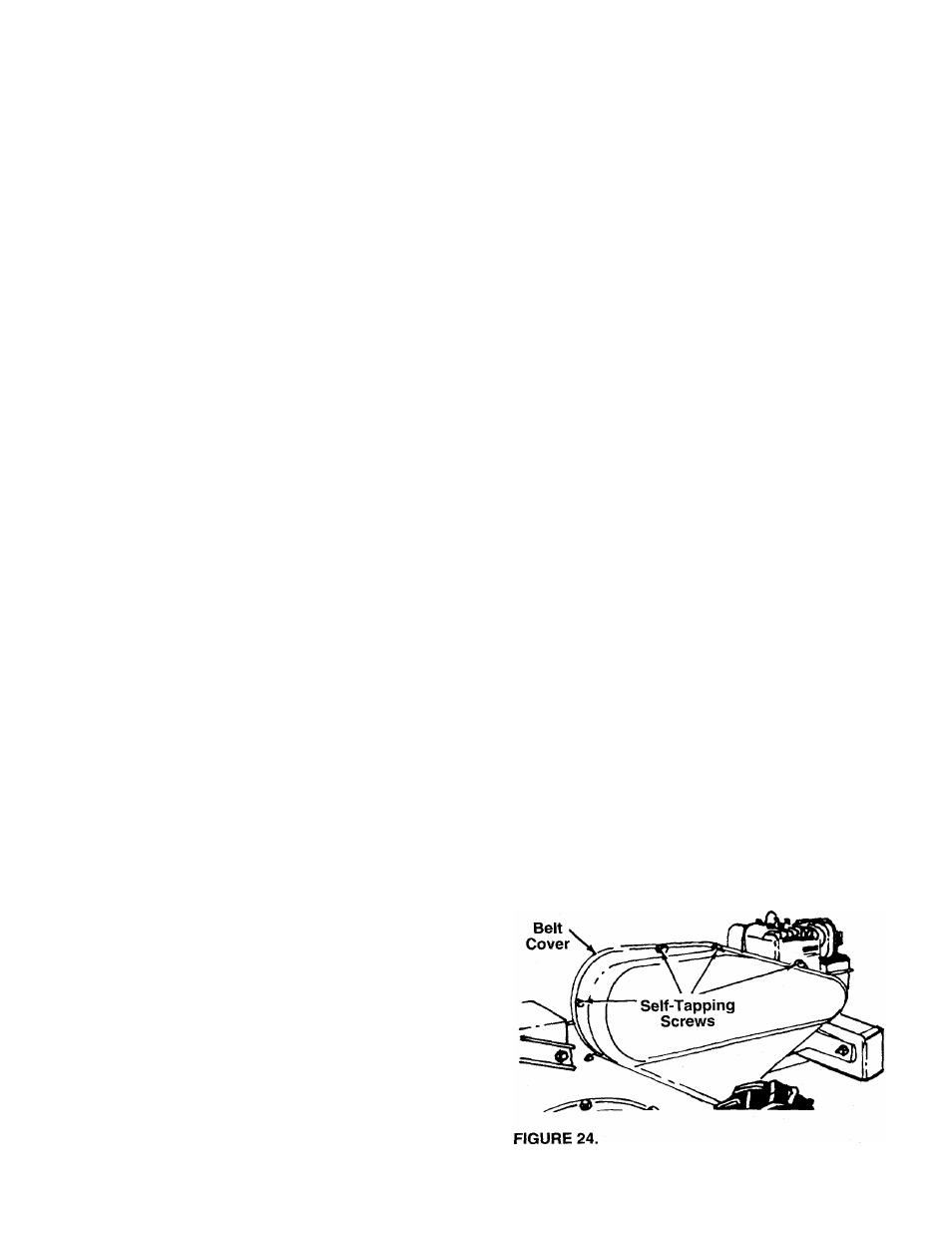

BELT REPLACEMENT

Your tiller has been engineered with belts made of

special material (Kevlar Tensile) for longer life and

better performance. They should not be replaced with

an off-the-shelf belt.

If belt replacement is required, order belt or belts by

part number from your nearest authorized dealer.

1. Remove belt cover by removing the four self-tap

ping screws. See figure 24.

12