Drive clutch – MTD 406 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

V,

DEPTH STAKE ADJUSTMENT

To adjust the depth stake, refer to “How To Use Your

Tiller” on pages 9 and 10.

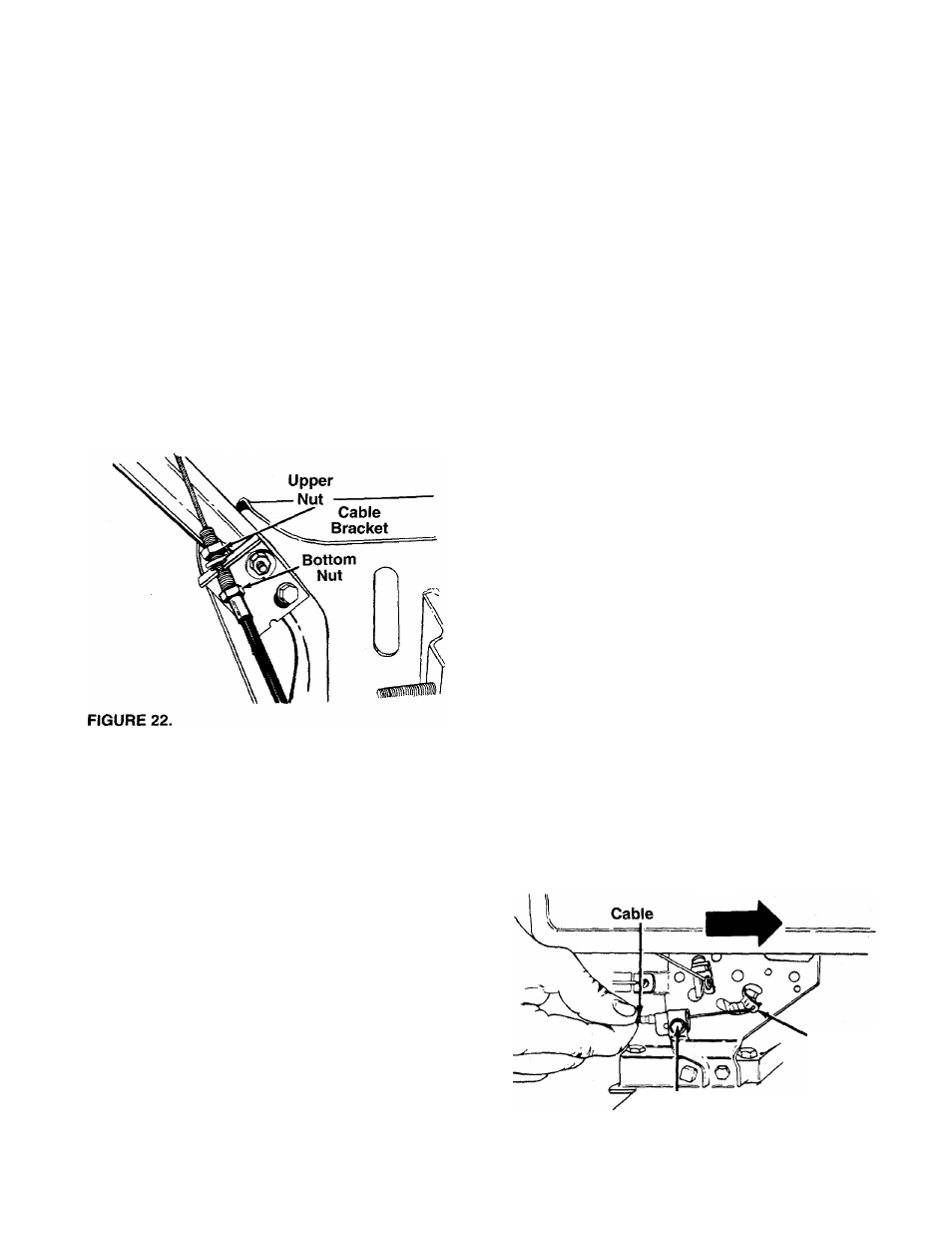

BELT TENSION ADJUSTMENT

Tine Clutch

Periodic adjustment of the belt tension may be

required due to normal stretch and wear on the belt.

Adjustment is needed if the tines seem to hesitate

while tilling, but the engine maintains the same speed.

To adjust, loosen the hex nuts at the cable bracket on

the handle. See figure 22. With the clutch lever

released as shown in figure 16, adjust the bottom nut

so that there is only a slight amount of slack in the

control wire. Tighten the upper nut against the brack

et.

NOTE:

Do not overtighten control wire. Too much ten

sion may cause it to break.

Drive Clutch

if adjustment is needed, refer to final adjustment sec

tion of Assembly instructions.

If through normal operation the belts become

stretched or worn, and there is no adjustment left at

the cable brackets on the handles and handle panel,

the other end of the cables may be adjusted as fol

lows.

a. If the tiller does not have forward motion with the

forward drive clutch lever engaged, adjust the for

ward drive cable by loosening the hex nut in back

of the cable bracket on the tiller a few turns, then

tightening the hex nut in front of the bracket. Refer

to figure 9.

b. If the tiller does not have reverse motion with the

reverse drive clutch lever in reverse, adjust the

reverse cable by loosening the hex nut in front of

the cable bracket on the tiller a few turns, then

tightening the hex nut in back of the bracket. When

correctly adjusted, the reverse idler should be

toward the middle of the slot as shown in figure 15.

When making either of the above adjustments (a or

b), be certain to recheck the neutral adjustments on

the tiller (steps A and B in first column on page 8).

CARBURETOR ADJUSTMENT

A

WARNING: If any adjustments are made

to the engine while the engine is running,

(e.g. carburetor), disengage all clutches

and tines. Keep ciear of ali moving parts.

Be careful of heated surfaces and muf

fler.

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude

or load. If adjustments are needed, refer to the engine

manual packed with the tiller.

NOTE:

A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the

carburetor

before

adjusting

carburetor.

Do

not

make

unnecessary

adjustments.

Factory

settings

are

satisfactory for most applications and conditions.

THROTTLE CONTROL ADJUSTMENT

To obtain satisfactory engine performance, the engine

throttle control must be adjusted properly. If it is nec

essary to check the engine control adjustments, pro

ceed as follows.

1. Loosen the cable clamp screw. See figure 23.

2. With the throttle control in FAST position and the

cable connected to the adapter lever, push the

cable through the cable clamp in the direction

shown in figure 23 until the adapter lever is as far

up as it will go.

3. Tighten the cable clamp screw.

4. Check that the engine stops when throttle control

is moved to STOP position. If engine does not

stop, loosen the cable clamp screw and readjust

by pulling cable backward slightly until engine

stops. Retighten cable clamp screw.

Adapter

Lever

Cable Clamp

Screw

FIGURE 23.

11