Adjustments, I warning, Wheel adjustments – MTD 219-320-000 User Manual

Page 12: Depth stake adjustment, Tine width adjustment, Tine clutch control adjustment, Carburetor adjustment, Note, Throttle control adjustment, Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ADJUSTMENTS

A

I WARNING

\

Disconnect the spark plug wire and

ground

against

the

engine

before

performing any adjustments, repairs,

or maintenance.

WHEEL ADJUSTMENTS

To adjust the wheel yoke and wheel position, r< fer to

“How To Use Your Tiller,” on page 10.

DEPTH STAKE ADJUSTMENT

To adjust the depth stake, refer to “How To Use Your

Tiller” on page 10.

TINE WIDTH ADJUSTMENT

To adjust the tine width, refer to “Cultivating” or page

11

.

TINE CLUTCH CONTROL ADJUSTMENT

To adjust the tine clutch control, refer to step number

4 on page 7.

CARBURETOR ADJUSTMENT

A

\

warning

{

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), disengage all clutches

and tines. Keep clear of all moving

parts. Be careful of heated surfaces

and muffler.

Minor carburetor adjustment may be requited to

compensate for differences in fuei, temper iture,

altitude or load. If adjustments are needed, re fer to

the engine manuai packed with the tiller.

NOTE

A dirty air cleaner will cause engine to

run rough. Be certain air cleaner is

clean and attached to the carburetor

before adjusting carburetor. Do not make

unnecessary

adjustments.

Factory

settings are satisfactory for most appli

cations and conditions.

THROTTLE CONTROL ADJUSTMENT

To obtain satisfactory engine performance, the ( ¡ngine

throttle control must be adjusted properly.

I f it is

necessary to check the engine control adjustrrients,

proceed as follows.

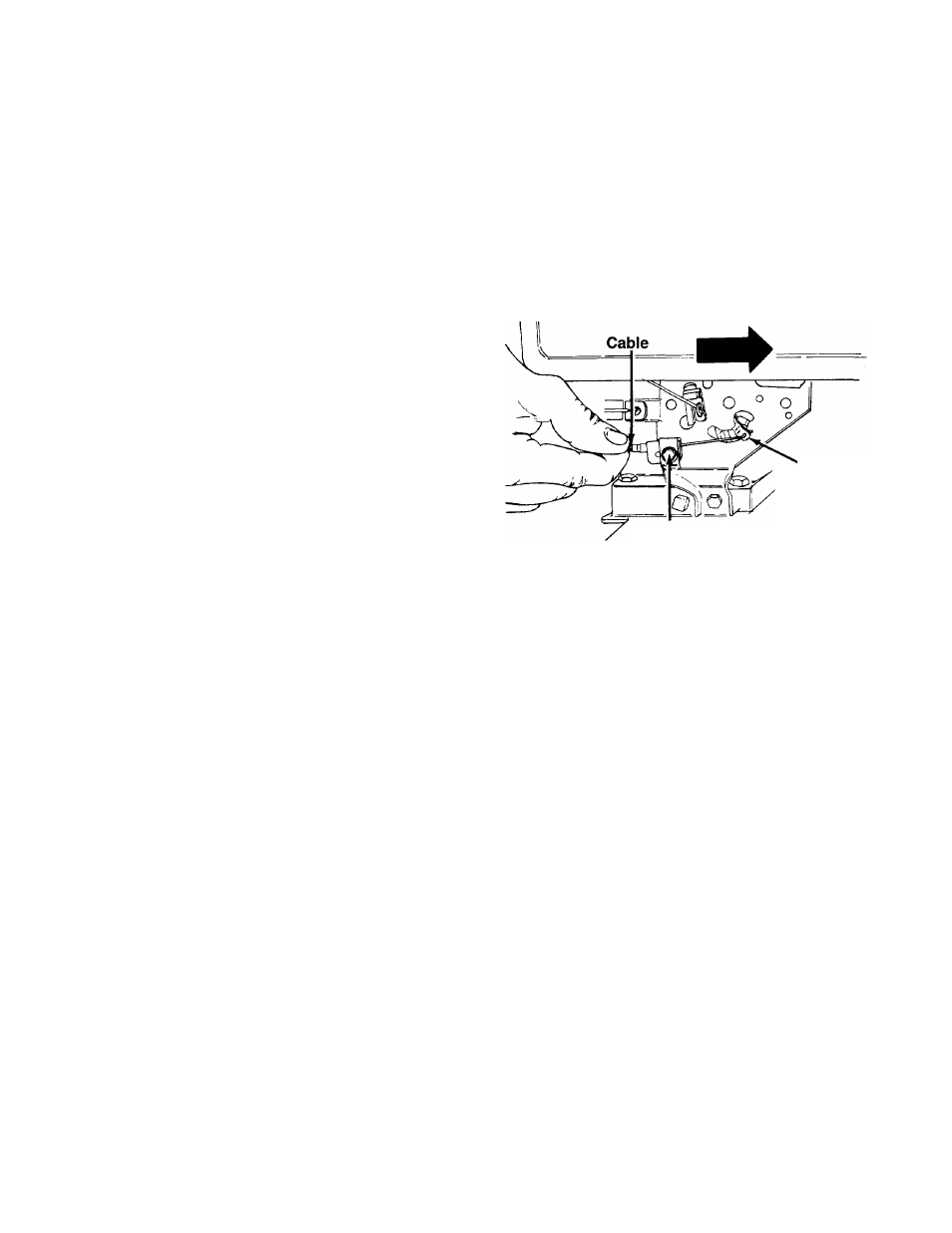

1. Loosen the cable clamp screw. See figure 23.

2. With the throttle control in FAST position (see

figure 16) and the cable connected to the adapter

lever, push the cable through the cable clamp in

the direction shown in figure 23 until the adapter

lever is as far up as it will go.

3. Tighten the cable clamp screw.

4. Check that the engine stops when throttle control

is moved to STOP position. If engine does not stop,

loosen cable clamp screw and readjust by pulling

cable backward slightly until engine stops.

Retighten cable clamp screw.

Adapter

Lever

Cable Clamp

Screw

FIGURE 23.

LUBRICATION

A

t

WARNING

Always stop engine and disconnect spark

plug wire before cleaning, lubricating

or doing any kind of work on tiller.

Pivot Points—Remove the belt cover and lubricate ail

moving parts and pivot points at least once a season

using SAE 30 engine oil.

Chain Case—The chain case is pre-lubricated and

sealed at the factory. It requires no checking unless the

chain case is disassembled. To fill with grease, lay the

left half of the chain case on its side, add 12 ounces

of Plastilube #0 grease and assemble the right half to

it. This grease can be obtained at your nearest autho

rized service dealer. Order part number 737-0133.

MAINTENANCE

A

I WARNING {

Disconnect spark plug wire and ground

it against the engine before performing

any repairs or maintenance.

12