Off-season storage – MTD 24645-8 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

LOG SPLITTER RESERVOIR FLUID

Check fluid level in log splitter reservoir before every

use. Refer to "Before Starting" under OPERATION

section.

,.-~jQhange the hydraulic fluid in the reservoir every 100

' burs of operation. Remove the six hex bolts, lock

.i/ashers and hex nuts which hold the end plate to the

beam. Remove the plate and drain the fluid. Be pre

pared to catch the fluid in a suitable container.

NOTE

Drain the fluid and flush the reservoir

tank assembly and hoses with kerosene

each time repair work is performed on

on the tank, hydraulic pump or valve.

Contaminants in the fluid will damage

the hydraulic components.

A

i WARNING t

END

PLATE

Use

extreme

caution

when

using

kerosene as it is an extremely flamm

able liquid.

HEX BOLTS

LOCK WASHERS

HEX NUTS

figure

18

When the hydraulic fluid is drained from the reservoir,

clean the strainer tube assembly as follows.

1.

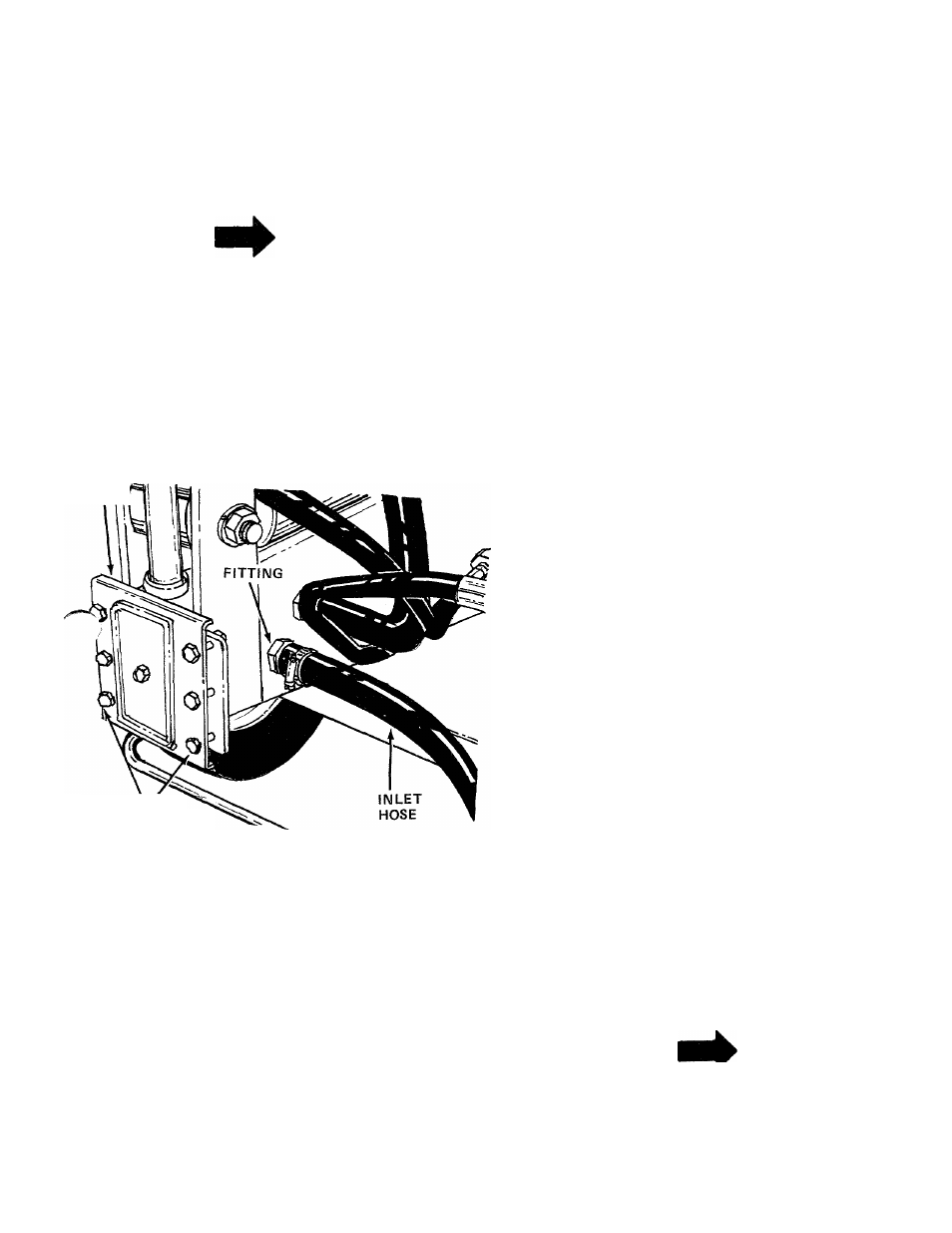

Remove the hose clamp at the inlet hose {bottom

hose). See figure 18.

2.

Pull the inlet hose off the fitting at the beam.

Using an adjustable wrench, remove the fitting

from the beam.

3.

Reach inside the end of the beam and pull out the

strainer tube assembly. See reference number 96

on page 12.

4.

Clean the strainer tube assembly with kerosene,

and reassemble in reverse order.

eassemble

the

end

plate.

Refill

reservoir

with

approximately 2-1/2 to 3 gallons of Dexron II auto

matic transmission fluid and bleed the air from the

hydraulic system as instructed in "Before Starting"

under OPERATION section.

HOSE CLAMPS

Check the hose clamps on the bottom of the pump

for proper tightness before each use. Hose clamps on

return hose should be checked once a season.

CARBURETOR ADJUSTMENTS

A

\

WARNING {

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), keep clear of all

moving parts. Be careful of heated

surfaces and muffler.

Refer to engine manual packed with your unit for

carburetor adjustment information.

TIRE PRESSURE

Check sidewall of tire for manufacturer's maximum

tire pressure. If this information does not appear on

your tire, maximum tire pressure under any circum

stances is 30 p.s.i. Equal tire pressure should be

maintained on all tires.

INSTALLATION OF TIRE TO RIM

A

J WARNING I

1

.

2

.

3.

The

following

procedure

must

be

followed when removing or installing

a tire to the rim.

Be sure rim is clean and rust free.

Lubricate both the tire and rim generously.

Never inflate to over 30 p.s.i. to seat beads.

Excessive inflation pressure when seating beads

may cause tire/rim assembly to burst with force

sufficient to cause serious injury.

OFF-SEASON STORAGE

If the machine is to be inoperative for a period

longer than 30 days, prepare for storage as follows.

1. Clean the engine and the entire unit thoroughly.

2.

Wipe the entire machine with an oiled rag to

protect the surfaces.

3.

Refer to the engine manual for correct engine

storage

instructions.

The

engine

must

be

completely

drained

of

fuel

to

prevent

gum

deposits from forming on essential carburetor

parts, fuel lines and fuel tanks.

4. Store unit in a clean, dry area.

NOTE

When

storing

any

type

of

power

equipment

in

an

unventilated

or

metal storage shed, care should be

taken to rust proof the equipment.

Using a light oil or silicone, coat the

equipment, especially all moving parts.

11