Compensating for restrictions, Testing the installation – Generac 0661-4 User Manual

Page 22

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

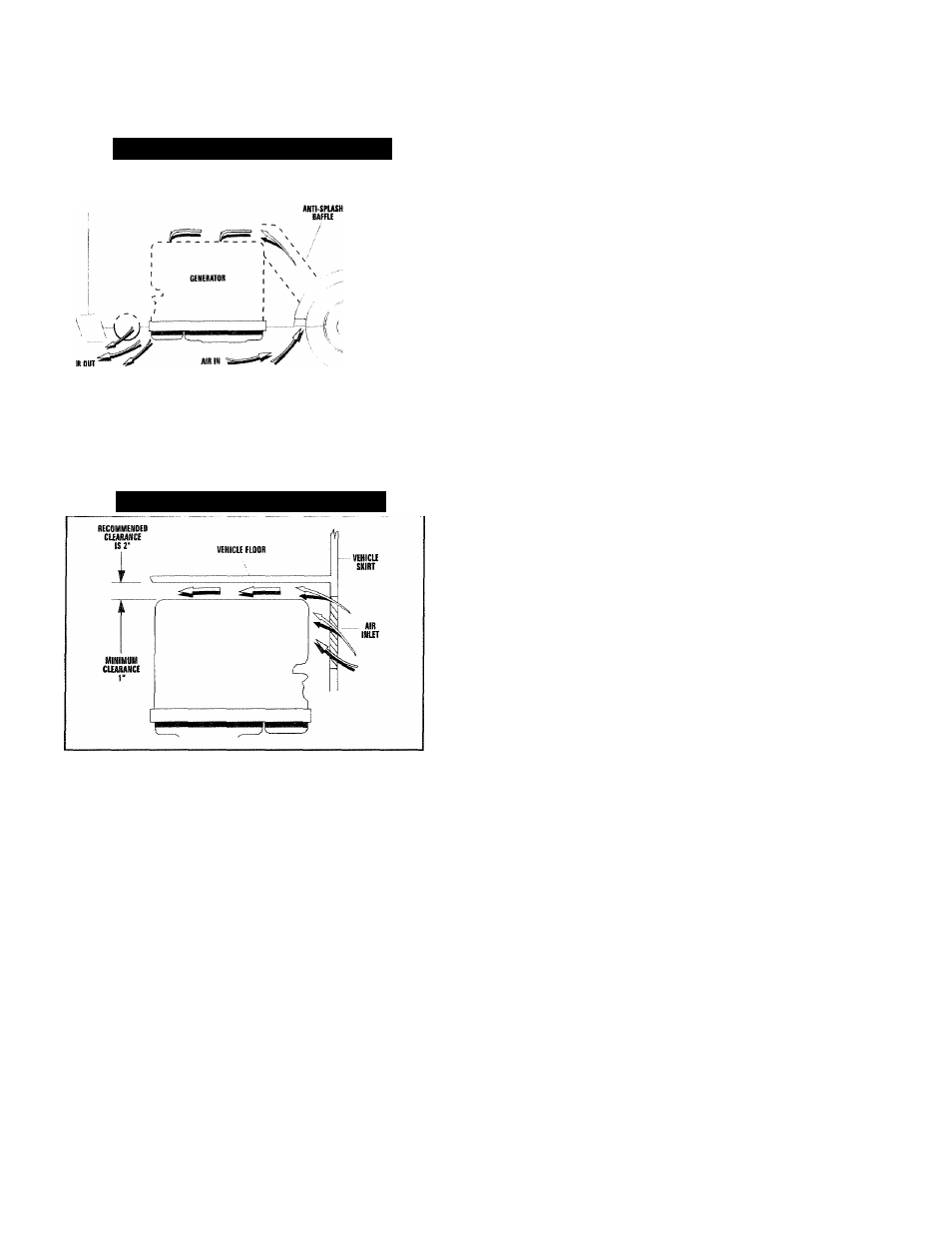

Using ductwork (Figure 23). The installer must be sure air

is available to the top of the generator since air inlets are

located at the top.

Figure 23 — Air Inlet Using Ductwork

By providing an opening in the vehicle skirt and space

above the generator for cooling air flow (Figure 24).

Recommended clearance above the top of the generator

is at least 2 inches.

Figure 24 — Air Inlet in Vehicle Skirt

COMPENSATING FOR

RESTRICTIONS

Such materials as screening, louvers, or expanded

metal can restrict the free flow of air. Compensate for

this restriction by making the actual air opening pro

portionately larger.

Some materials may offer only a 60 percent “free air

inlet area.” Other more efficient materials may provide

up to a 90 percent free air inlet area. The percentage

of free air inlet opening is usually available from the

material supplier or manufacturer.

TO DETERMINE THE ACTUAL AIR INLET OPEN

ING SIZE REQUIRED, DIVIDE 40 SQUARE INCHES

BY THE PERCENTAGE OF FREE AIR INLET AREA

FOR THE MATERIAL YOU WILL USE.

For example: If you plan to use screening with an

80% free air inlet area, divide 40 by 0.8, which results

in 50 square inches. Minimum actual size of air inlet

opening in this case is 50 square inches. An opening

that measures 4 inches wide by 12-1/2 inches long

provides the required air flow (4 x 12.5 = 50 square

inches).

TESTING THE INSTALLATION

Generac recommends testing the installation to be

sure adequate cooling air flow is available to the unit

before placing the unit into service. If the unit shows

signs of overheating, you will need to enlarge the air

openings.

Never place a unit into service until

absolutely certain that cooling and ventilation is ade

quate.

IMPORTANT: YOU MUST TEST THE INSTALLA

TION ESPECIALLY IF YOU BRING IN AIR FROM

BELOW THE GENERATOR SET.

20

—