Compartment size, Compartment construction, Sound insulating materials – Generac 0661-4 User Manual

Page 19: Compartment seams

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

COMPARTMENT SIZE

Plan the compartment size carefully. Provide a mini

mum of at least 1 inch (2” recommended) of clearance

between the generator and compartment walls and

1 inch (2” recommended) of clearance between the

generator and the ceiling AFTER you have lined the

compartment

with

metal,

and

AFTER

you

have

installed sound insulation (Figure 16).

NOTE: Refer to the “Dimensions and Features” draw

ing in the back of this manual.

Figure 16 — Provide Clearance Around Generato

PLYWOOD

COMPARTMENT

TOP VIEW OF

GENERATOR

11NCH MINIMUM CLEARANCE

ON ALL SIDES

|2"

RECOMMENDED)

1 INCH

MINIMUM

CLEARANCE

ABOVE

GENERATOR

(2”

RECOMMEND

ED)

METAL UNING-

—INSULATION

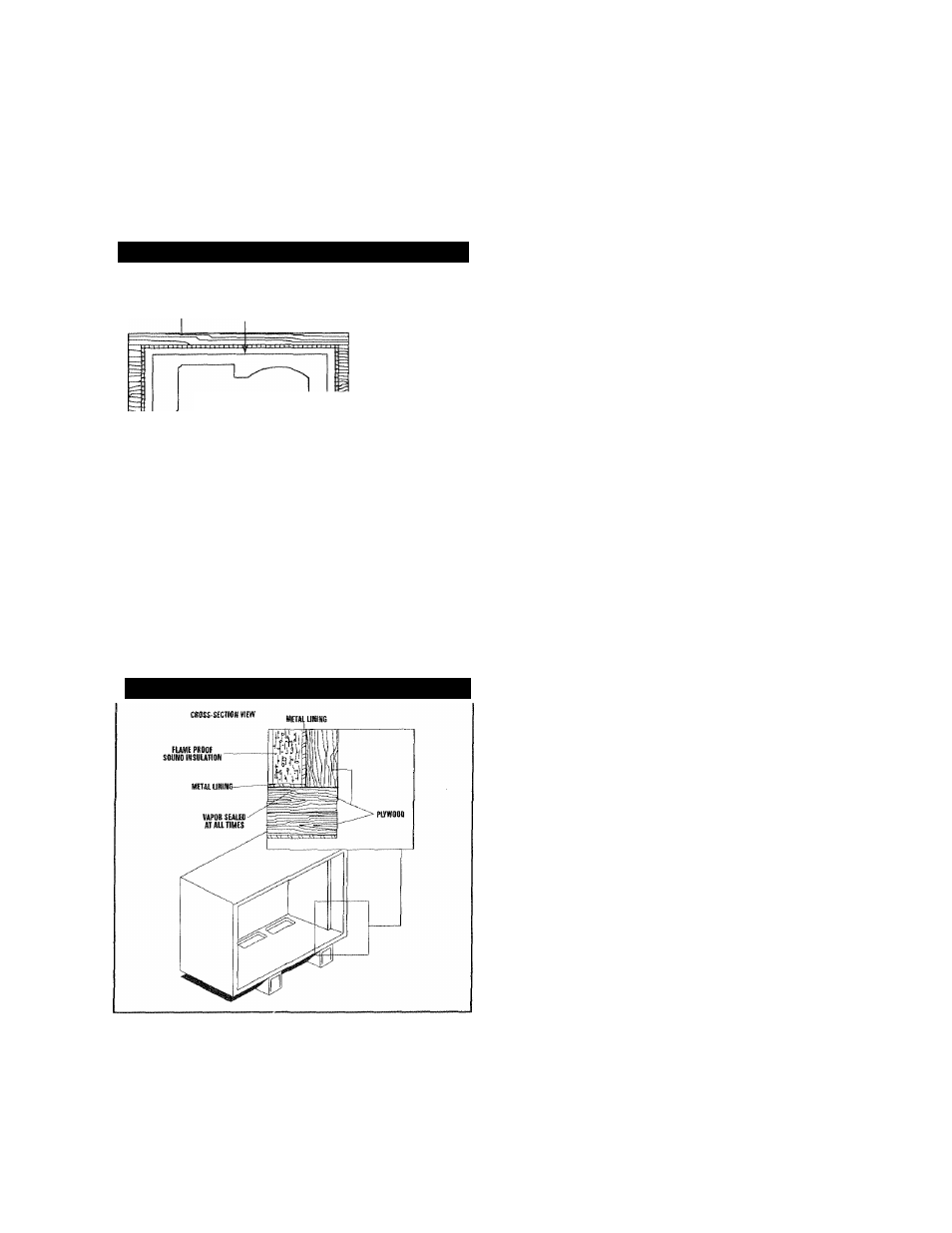

COMPARTMENT CONSTRUCTION

The

generator

compartment should

be

constructed of

1/2

inch thick

plywood. Make

the compartment floor a double

thickness of 1/2 inch

plywood

with

the

grain of the wood

at

cross section for added strength (Figure

17).

Figure 17 — Typical Compartment Construction

Line the entire compartment interior with 26 gauge galva

nized steel as described above.

Line the exterior (underside) of the compartment floor

with 26 gauge galvanized steel.

A

• Vapor seal

all compartment seams and joints, to prevent

poisonous, flammable or explosive vapors from entering

the vehicle interior. Refer to the sealant information as

noted below.

NOTE: Silicone rubber base sealant is an acceptable

caulking material. Pressing putty tape onto compart

ment joints and seams is

NOT acceptable.

•

After the compartment has been metal lined and

vapor sealed, line the compartment interior walls

and ceiling with an approved, non-flammable

sound insulating material. See “Sound Insulating

Materials.”

DANGER: DO NOT INSTALL SOUND INSU

LATION OR ANY ABSORBENT MATERIAL

ON THE COMPARTMENT

FLOOR INTERI

OR.

SUCH

MATERIALS

WILL

BECOME

SOAKED WITH COMBUSTIBLE OR EXPLO

SIVE

VAPORS

AND

LIQUIDS

AND

WILL

BECOME A FIRE HAZARD.

•

Openings in compartment walls for passage of

electrical conduit, conductors, hoses, cables, etc.,

must be made vapor tight with suitable caulking

material.

•

Flexible conduit must be sealed internally at the

end where it terminates inside a compartment's

electrical junction box.

NOTE: The preceding is required because flexible

conduit, due to its unique construction, is not vapor-

tight along its entire length.

DANGER: DO NOT INSTALL ANY FLAMMABLE

MATERIAL DIRECTLY ABOVE OR AROUND THE

COMPARTMENT. HEAT, TRANSFERRED THROUGH

THE COMPARTMENT STRUCTURE, MAY BE SUF

FICIENT TO IGNITE, CHAR OR DISCOLOR SEAT

CUSHIONS, FIBERBOARD AND OTHER FLAMMA

BLE MATERIALS. YOU MAY NEED TO USE

APPROVED NON-FLAMMABLE INSULATING

MATERIALS IN HIGH TEMPERATURE AREAS.

A

SOUND INSULATING MATERIALS

Once installers have determined that compartments

are properly constructed and metal lined, they can

add acoustical material. This may include additional

sealant or Insulating material, to reflect noise away

from the vehicle interior.

Sound insulating materials should be of a non-flam

mable type. One excellent insulating material is a 1

inch thick fiberglass having a 2-pound density. When

fiberglass is used, its coated side should face toward

the compartment interior.

Using a combination of sound insulating materials can

often reduce noise more effectively than a single

material. For example, a sheet of lead or visco-elastic

material, along with a layer of other acoustical materi

al, is more effective than when a single material is

used.

—17

—