1>ecejue;rat10n check, Low speed mixture adjustment, High speed mixture adjustment – Poulan 1600 User Manual

Page 17: Bas1c carburetor settings, Re1nstall air filter, Air filter, D. air filter

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

4.1>ECEjUE;RAT10N CHECK

a. Allow engine to idle, then squeeze Throttle Trigger

fully.

b. Allow engine to mn at full speed for about 1 second.

c. Release the Throttle Trigger to the idle position and

listen to the deceleration of the engine. It must return

to idle smoothly and within 1 to 2 seconds.

1.

)K performance is satisfactory’,

proceed to step

“d.”

2.

)If the engine slowly or erratically returns to

idle or idles erratically,

repeat “2. Idle Speed

Adjustment” or continue through Low Speed

Mixture and High Speed Mixture Adjustments to

obtain proper deceleration.

d- Recheck idle speed.

5. LOW SPEED MIXTURE ADJUSTMENT

a. Allow engine to idle.

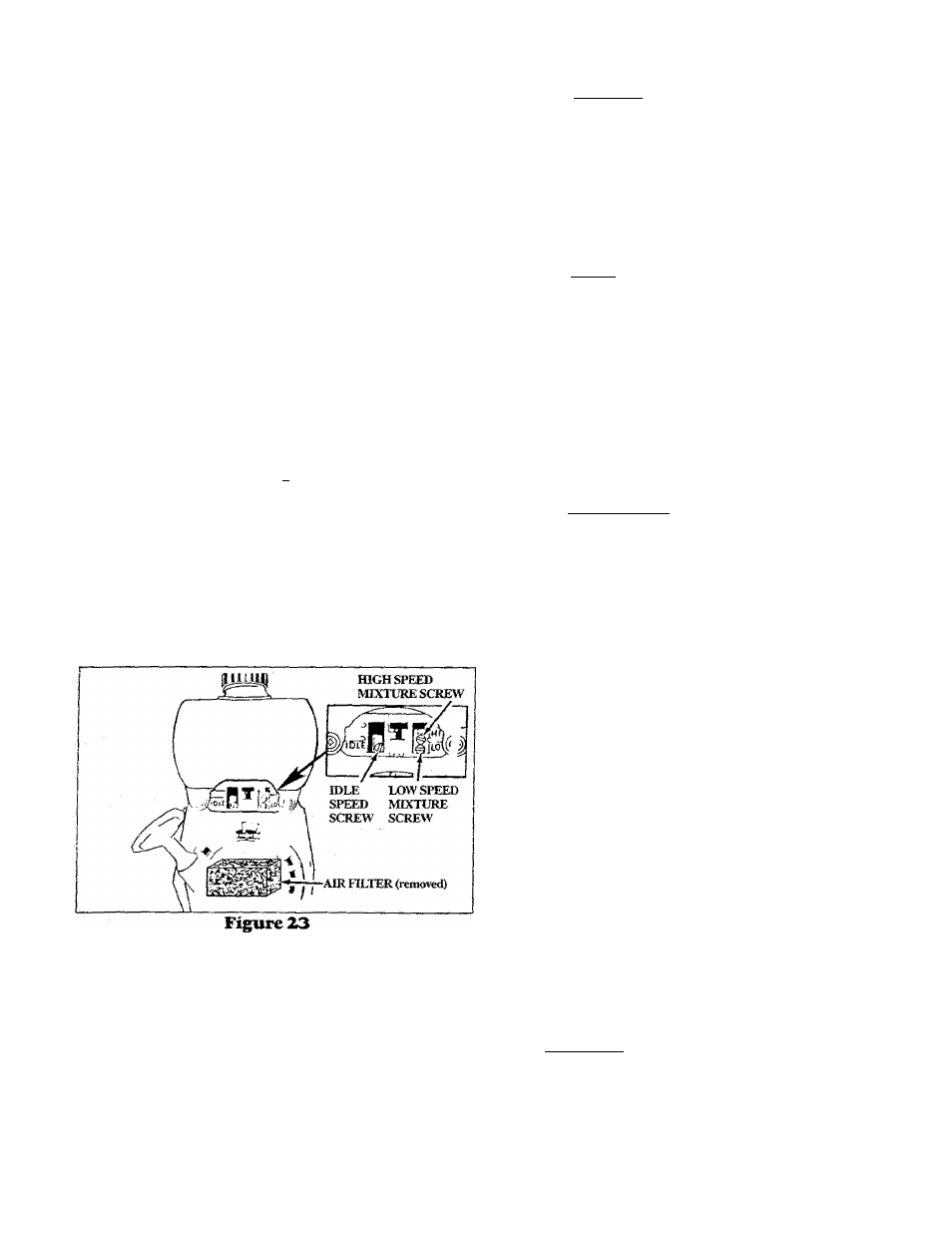

b. Turn the Low Speed Mixture Screw (Figure 23)

slowly clockwise ^ k until the speed starts to

drop. Note this position.

c. Turn the Low Speed Mixture Screw counterclock

wise

until the speed increases and then starts

to drop again. Note this position.

d. Set the Low Speed Mixture Screw at the mid-point

between the two positions.

e. Follow instructions in “3. Acceleration Check” and

“4. Deceleration Check,”

6. HIGH SPEED MIXTURE ADJUSTMENT

fCAUTlQ]^

Do

not

operate

engine

at

full

throttle for prolonged periods while making high

speed adjustments as damage to the engine can

occur.

a. Support the drive shaft housing so the trimmer line

is off the ground and wiU not make contact with any

object.

b. Allow engine to idle, then squeeze Throttle Trigger

Mly.

NOTE: Perform steps “c.” through “e.”, at full

throttle.

c. Turn High Speed Mixture Screw (Figure 23) very

slowly clockwise ^ until engine speed is

reduced.

d. I\xm High Speed Mixture Screw very slowly

counterclockwise 4^^ .Stop when the engine just

begins to run rough.

e. Turn the screw slowly the nunimuin amount clock

wise

until the engine runs smoothly.

f. Follow instructions in “3. Acceleration Check” and

“4. Deceleration Check.”

I

CAUTION:

I

If the engine does not operate

according to these instructions after repeating the

adjusting steps, do not use the tool- Take it to a

qualified service dealer,

7. BAS1C CARBURETOR SETTINGS

a. Turn the Low Speed Mixture Screw and the High

Speed Mixture Screw (Figure 23) clockwise

A

just until they stop. Do not turn the screws until they

are tight as damage to the needle seats can occur.

b. Turn the Low Speed Mixture and High Speed Mix

ture Screws one full turn counterclockwise 4—^ .

c. Follow instructions “1. Preparation,” through “6.

High Speed Mixture Adjustment.”

8. RE1NSTALL AIR FILTER

Be sure filter is clean. See “Air Filter” for instmctions.

CAUTION:

Fit air filter into the corners of the

housing to keep dirt from entering the engine and

causing engine damage.

0. AIR FILTER

A dirty air filter decreases the life and performance of the

engine and increases fuel consumption.

Clean the Air Filter:

• Always after 5 tanks of fiiel or 5 hours of operation,

whichever is less.

• More frequently, in dusty conditions,

1. Pull the Air Filter from the engine with you fingers. For

Air Filter location, see “Specifications.”

2. Wash in soap and water.

ICAUTIO

n

T]

Do

not

clean

the

air

filter

in

gasoline

or

other

flammable

solvent

to

avoid

creating a fire hazard.

3. Squeeze dry and replace.

1 CAUTION: i

The air filter must be fitted into

the corners of the housing to avoid engine damage.

17