Step 7: add motor oil to engine, Step 8: attach engine throttle lever and cable, A warning – Troy-Bilt 12090 User Manual

Page 9: Step 9: adjust air pressure in tires, Important

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 2: Assembly

IMPORTANT:

Check gear oil level in both

transmissions after the first 2 hours of

new tiller operation, then every 30

operating hours thereafter. See Section 5

for instructions.

Figure 2-13: Checking oii ievel on

Tine Attachment Transmission.

STEP 7: Add Motor Oil to Engine

1. Before adding motor oil, park the tiller

on ievel ground. Level the engine by

placing a sturdy block under the tines or

the tines depth regulator bar.

2. Add high-quality, API-rated motor oil

to engine before starting. Refer to the

Engine Owner’s Manual provided with

your tiller for detailed information on how

to add motor oii and for motor oil

specifications.

IMPORTANT:

• Change engine oil after first 2 hours of

new operation.

• Check engine oil level every 5 hours of

operation or each use.

STEP 8: Attach Engine Throttle

Lever and Cable

For shipping purposes, the throttle cable,

together with the throttle lever, is wound

around the engine. Carefully unwind the

cable. If the throttle control label is

covered with a clear protective coating,

peel it off.

A

WARNING

To avoid electric shock from a short

circuit (electric start tillers only), never

allow the throttle cable to touch the

battery. Route cable below the battery,

on the outside of the battery holder.

To attach the throttle lever and cable:

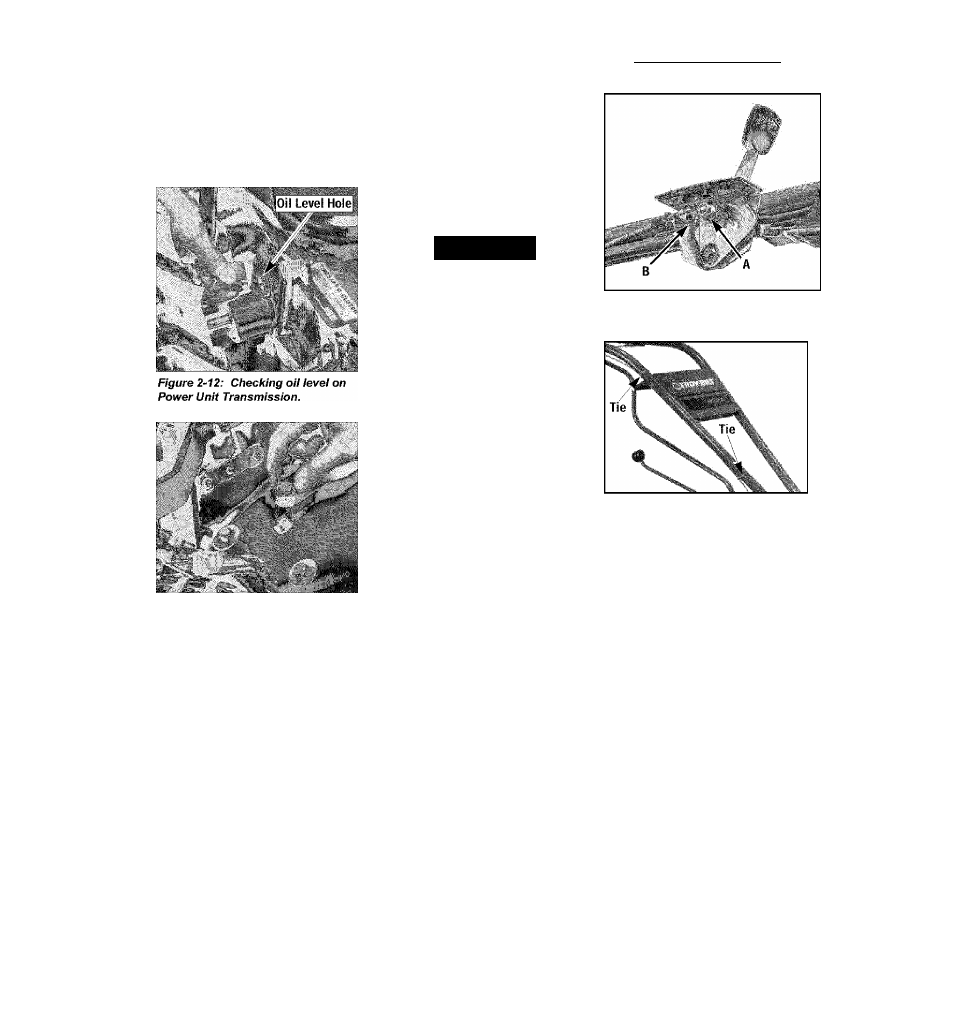

1. Run the throttle cable up the inside

edge of the right handlebar and position

the lever as shown in Figure 2-14.

2. From the outside of the handlebar,

insert the curved head screw (A, Figure 2

14), through the handlebar and the center

hole in the throttle lever mounting

bracket.

3. Loosely install the flanged lock nut

and move the throttle lever back to the

STOP position.

4. From the lever side of the bracket,

thread a pan head screw (B, Figure 2-14)

through the small hole in the throttle lever

bracket and Into the handlebar. Tighten

the screw securely.

5. Securely tighten both the flanged lock

nut and the curved head screw.

6. Use two plastic ties to secure the

throttle cable to the right handlebar in two

places (Figure 2-15). Loop each tie

around the handlebar and cable (serrated

side faces in) and pull the ties tight. Trim

the ends.

Figure 2-14: Engine Throttle Lever

position and installation.

Figure 2-15: Plastic Ties placement

on handlebars.

STEP 9: Adjust Air Pressure in

Tires

For shipping purposes, the tires may be

overinfiated. Check the air pressure in

each tire and adjust them to between 10

and 20 pounds per square inch. You

must inflate each tire to equal air

pressures to prevent the tiller from pulling

to one side.

Assembly is complete for recoil start

tillers. See Assembling The Electric

Start System If you own an electric

start tiller; otherwise, refer to Section

3, Controls tor information on tiller

controls.