Handle position, Figure 9, Carburetor adjustments – MTD 112-162A User Manual

Page 7: Warning, Lubrication, Important

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

one hole to another. Simply depress thumb lever

towards wheel and move wheel and lever

assembly to desired position. All wheels must be

placed in the same relative position.

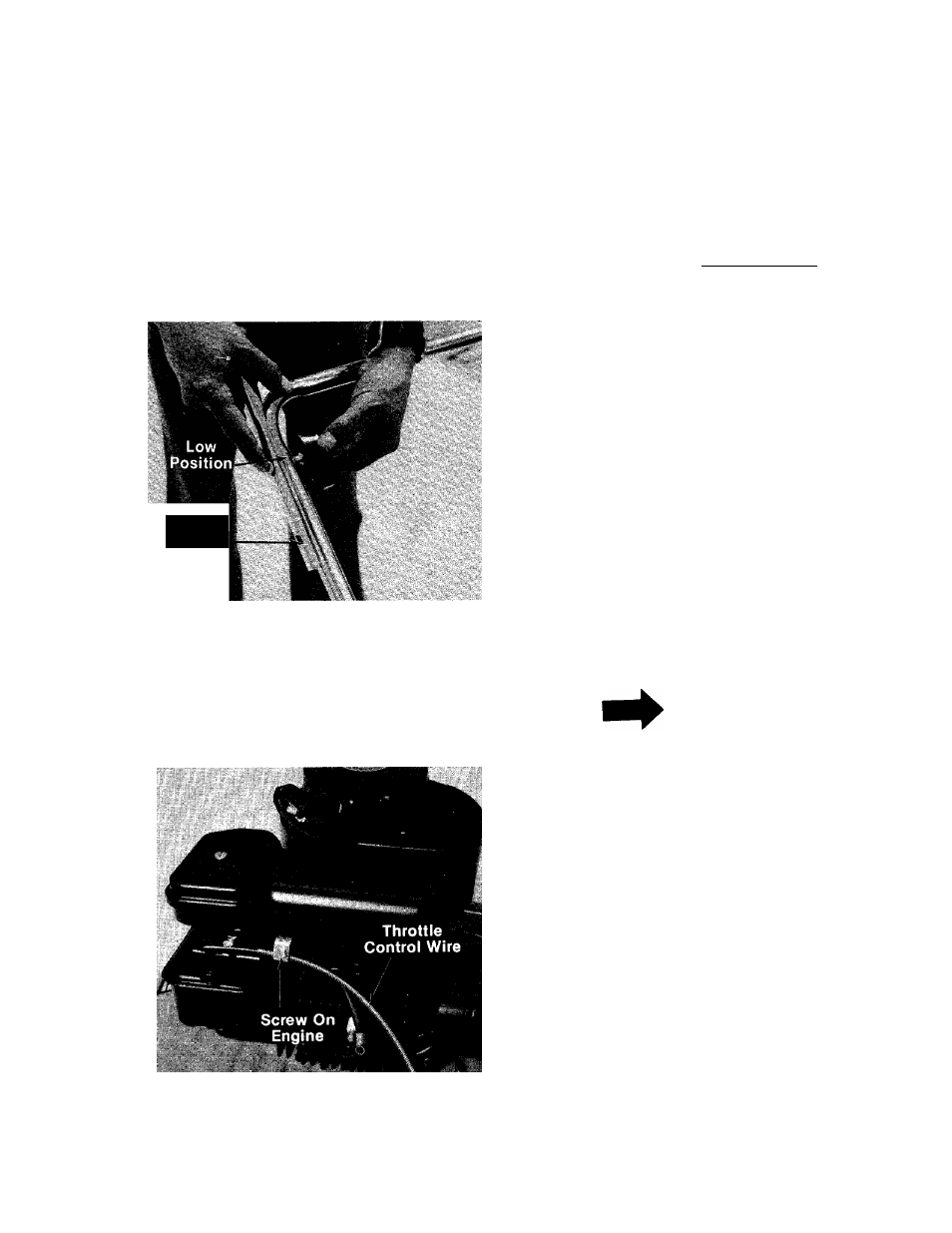

HANDLE POSITION

The upper handle can be adjusted to a high or low

position. The operator of the lawn mower can easi

ly adjust the handle position by unscrewing the

two knobs, removing the two bolts and reassem

bling in the other position. No tools are necessary

to make this adjustment. See figure 8.

High

Position

FIGURE 8.

THROTTLE

If adjustment becomes necessary, the throttle

control wire assembly can be reset as follows:

1. Loosen, but do not remove, screw securing

throttle control wire assembly at engine. See

figure 9.

FIGURE 9.

2. Move throttle control lever on handle to

“FAST” position.

3. Move lever, to which control wire is fastened

at engine, to full open position and retighten

screw to secure throttle control wire

assembly.

CARBURETOR ADJUSTMENTS

\

WARNING

\

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), disengage all

clutches and blades. Keep clear of

all moving parts. Be careful of

heated surfaces and muffler.

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

All carburetor adjustments should be made with

the air cleaner on engine. Air cleaner mounting

screw must be in carburetor when engine is run.

Best adjustment is made with a fuel tank half full

of gasoline.

To adjust the carburetor, refer to the separate

engine manual packed with your mower.

LUBRICATION

IMPORTANT

Always stop engine and disconnect

spark plug wire before cleaning,

lubricating or doing any kind of

work on lawn mower.

Wheels—Wheel bearings are of self-lubricating

Fortiflex. They require no lubrication. However, if

the wheels are removed for any reason, lubricate

the surface of the axle bolt and the inner surface

of the wheel with light oil. A 4 oz. plastic bottle of

light oil lubricant is available. Order part number

737-0170. Engine oil may also be used.

If your unit is provided with optional ball bearing

wheels, lubricate at least once a season with light

oil.

Protective Shield—The pivot points on the protec

tive shield should be lubricated periodically with

light oil to prevent any rust or binding.

Chute Deflector—The torsion spring and pivot

point should be lubricated periodically with light

oil to prevent any rust or binding. Deflector must

work freely.