Strainer tube assembly, Hose clamps, Stroke return stop plunger – MTD 24638L User Manual

Page 10: Figure 17 ram operation, Carburetor adjustments, If i

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3. Replace check pipe plug. Remove block from

under front of beam.

OIL CHECK PIPE PLUG

FIGURE 15

Change oil in the reservoir every (100) hou s of

operation.

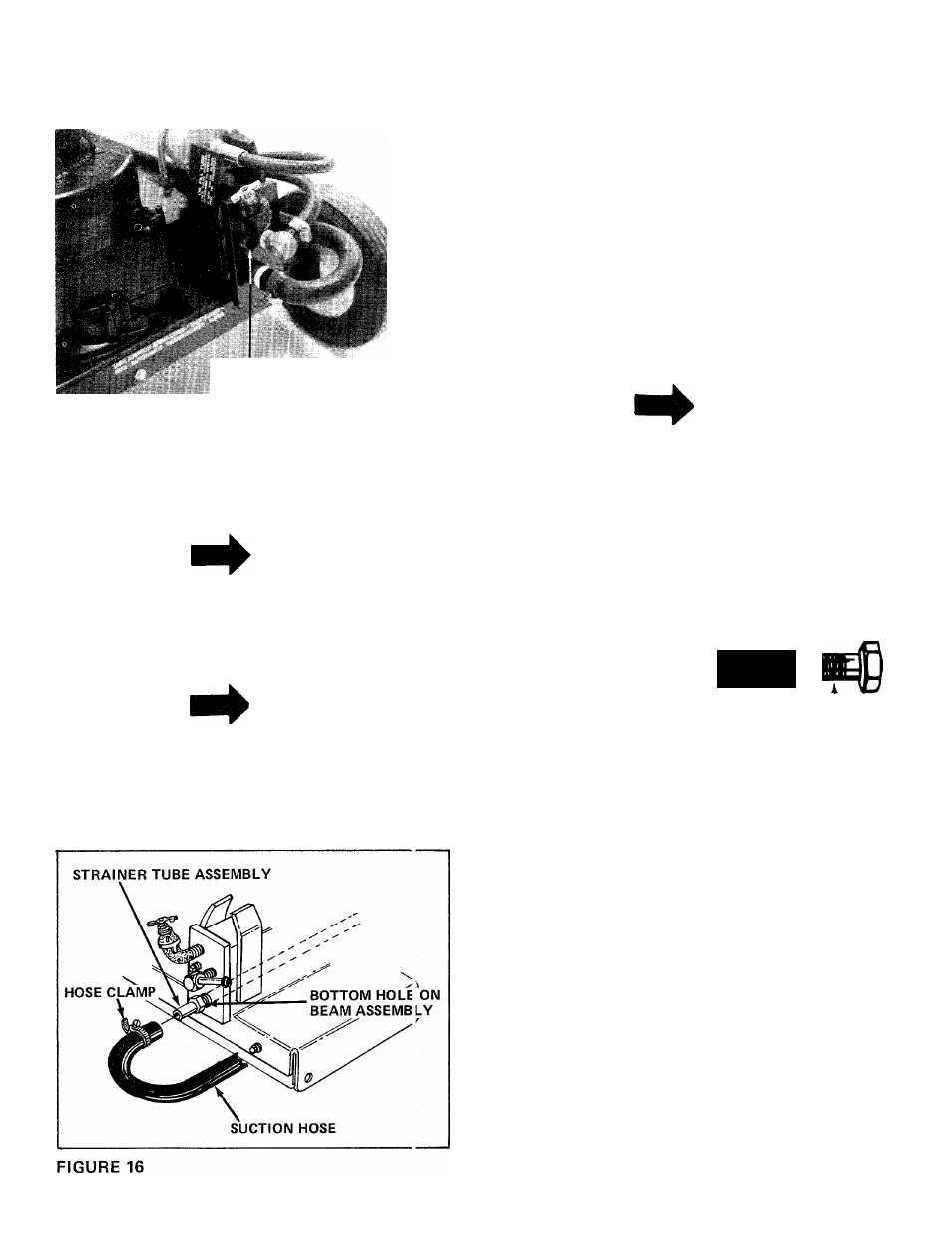

1. Remove the hose clamp at inlet hose (bottom

hose on rear of beam). See figure 16.

NOTE

Be prepared to catch oil in a suitable

container.

2. Pull off inlet hose from strainer tube assembly^ and

catch oil in a suitable container. See figure 1£.

3.

With an adjustable wrench remove the strainer

tube assembly. See figure 16.

NOTE

The strainer tube assembly is 42" long.

4.

Drain oil, clean strainer tube and reassemble

using a hydraulic pipe sealant on the threads.

5.

Remove the breather plug from breather :ube.

See figure 7. Pour approximately 2 galloris of

Dextron II transmission fluid ONLY into breither

tube.

STRAINER TUBE ASSEMBLY

If the ram does not move back and forth smoothly,

the strainer tube assembly may be clogged.

To clean, follow instructions for changing the reservoir

oil, step number 1 through 3. Clean the strainer tube

assembly and reassemble using a hydraulic pipe sealant

on the threads.

HOSE CLAMPS

Check the hose clamps on the bottom of the pump

for proper tightness before each use.

Hose clamps on the return hose should be checked

once a season.

STROKE RETURN STOP PLUNGER

If the engagement handle does not return to neutral

(from reverse) before the pressure relief bypass opens,

loosen the hex lock nut, and back out the hex bolt

one or two turns. See figure 17.

NOTE

When the pressure relief valve opens,

a loud high pitohed sound is heard and

engine labors.

Tighten hex lock nut and operate log splitter. Repeat

if necessary.

HEX BOLT

/if I

STROKE RETURN

STOP PLUNGER

HEX NUT

FIGURE 17

RAM OPERATION

If the ram does not move smoothly, run the ram its

full stroke several times to clear out air in the system.

Be sure the breather valve is open.

If this does not correct the problem, see Strainer Tube

Assembly paragraph.

CARBURETOR ADJUSTMENTS

I WARNING {

If any adjustments are made to the

engine while the engine is running

(e.g. carburetor), keep clear of all

moving parts. Be careful of heated

surfaces and muffler.

Refer to engine manual packed with your unit for

carburetor adjustment information.

10