Mower blade, Lubrication and maintenance (continued) – Ariens 912 User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Lubrication and Maintenance (Continued)

With Speed Selector in neutral “N”, remove five

cap screws holding friction wheel to hub. (If

necessary, use a 5/8" wrench on brake drum end

of hex shaft to keep friction wheel from rotating.)

Remove cap screw and lock washer that secures

ball joint to sliding fork and remove ball joint

from fork.

Remove cotter pin from brake rod and rod from

clutch brake bellcrank.

Remove master link from roller chain.

Remove two cap screws that secure carrier

bracket to frame, rotate lower end of carrier out

of frame and tie or brace it up.

Remove lock nut securing brake drum to hex

shaft. (Use a 5/8” wrench on brake drum end of

hex shaft to keep it from rotating.) Remove brake

drum and key from shaft.

On sprocket end of hex shaft, remove four lock

nuts that secure bearing flanges to frame.

Pull hex shaft from sprocket end far enough to

remove friction wheel and hub.

Install new friction wheel in reverse order being

sure that all hardware is tightened securely.

A

A

WARNING: Stop engine, remove key, wait

for moving parts to stop and remove wire

from spark plug before attempting any

maintenance procedures.

CAUTION: Wear of mower blade will cause

structural weakness. DO NOT install new

or replacement vanes on worn blades.

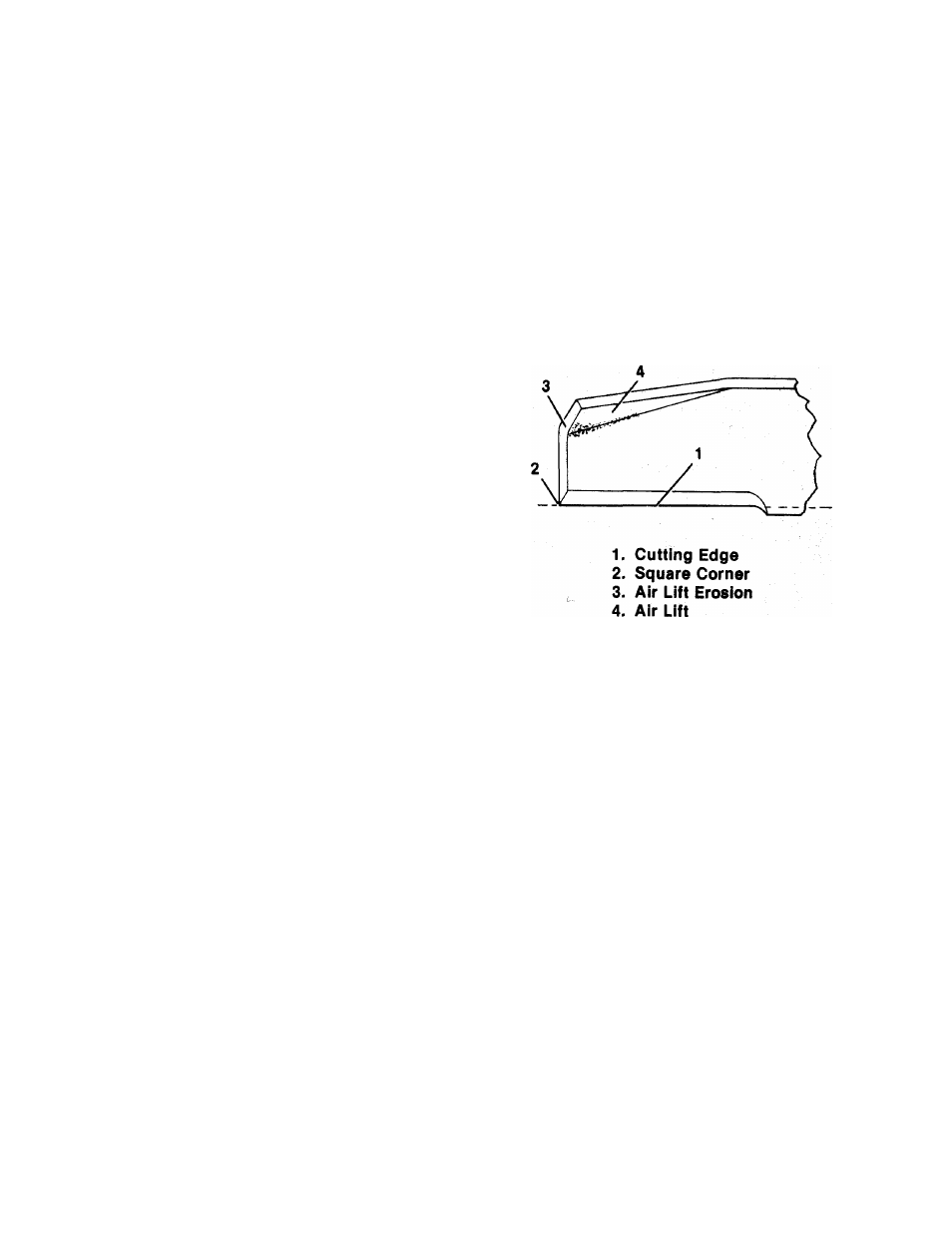

Figure 11: Mower Blade

A

CAUTION: After installation of new friction

wheel, check neutral setting, clutch and

brake adjustment per instructions in Ad

justments section of this manual.

Mower Blade

A

CAUTION: Use sturdy gloves or padding to

protect hands when working with mower

blades.

Regularly check mower blades (vanes if used) for

wear and that lock washer is fully compressed

by nut (requires 50-60 ft. lbs of torque on nuts).

When blade needs sharpening, block blade to

prevent rotation, remove nut, lock washer and

blade from shaft.

Sharpen both ends of blade at original angle (25

degrees), removing equal amounts of material

from each end to maintain proper blade balance.

New blades are balanced to within 1.3 inch

ounces at factory, DO NOT grind around corner

at tip of blade. If cutting edge of blade cannot be

sharpened in a straight line to within 1/8 of an

inch of its end, replace blade with Ariens

replacement blade only. Blades are available

through your Ariens Dealer.

Install blade, lock washer and tighten nut until

lock washer is fully compressed (requires 50-60

ft. lbs. of torque on nuts).

IMPORTANT: If mower is used under sandy soil

conditions, replace blades when air lifts become

eroded through at end.

16