Lubrication and maintenance schedule, Changing, Air cleaner – Ariens 912 User Manual

Page 14: Checking, Lubrication and maintenance (continued)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Lubrication and Maintenance (Continued)

Lubrication and Maintenance Schedule

Hours of Operation/

Time intervai

Service Required

Every 5 Hours

Or Daily

Every 10 Hours

Every 25 Hours

Every 100 Hours

Or Annually

Check Engine

Crankcase Oil

Oil bell crank and pivot

points.

‘Service Engine Air

Cleaner

‘Change Engine

Crankcase Oil

Service Battery

Check Tire Pressure

Grease Steering

System and

Front Axle Spindles

Left Rear Axle

Carrier Shaft

Friction Wheel Hub

Clutch Brake Arm

Check Spark Plugs

‘Clean or Replace Air

Filter Cartridge

‘Clean Engine Cooling

Fins

‘Under extremely dusty dirty conditions it may

be necessary to Service more often.

IMPORTANT: DO NOT over fill. Level must not ex

ceed full (F) mark. Oil level MUST be maintained

in safe operating range on dipstick at ail times or

engine damage will result.

Changing

IMPORTANT: Change oil after first 2 hours of

operation, thereafter change oil every 25 hours

of operation (more often in dusty, dirty condi

tions). See chart for proper type and viscosity.

NOTE: Run engine just prior to changing oil. Oil

will flow more freely and carry away more con

tamination when warm.

Drain engine crankcase by removing oil drain

plug. After oil has drained replace plug.

Remove oil fill cap with dipstick and pouring

slowly, add oil to crankcase to full mark on

dipstick (approximately 27 ounces -1-3/4 pints)

of oil. Check oil level with dipstick being sure

that you replace dipstick and tighten cap firmly.

Air Cleaner

IMPORTANT: DC NCT run engine with air

cleaner removed. Cperatihg engine with an ex-

trernely dirty air cleaner for only a brief period of

time can cause engine darnage.

Inspect air cleaner every twenty-five (25)

operating hours. (More often if unit is used under

extremely dirty or dusty conditions.)

Checking

The engine crankcase oii shouid be checked dai

ly or every 5 hours of operation.

To check oil, park riding mower on a flat level

surface, stop engine, and wipe all debris from

around dipstick cap.

Turn cap, remove dipstick from engine and wipe

oil off dipstick, Insert dipstick into fill hole and

turn slowly until cap bottoms firmly. Remove

dipstick and observe oil level. If low, add clean

fresh oil (of same type and viscosity as is in

engine) to bring oil level to full (F) mark. Replace

dipstick being sure to tighten cap firmiy.

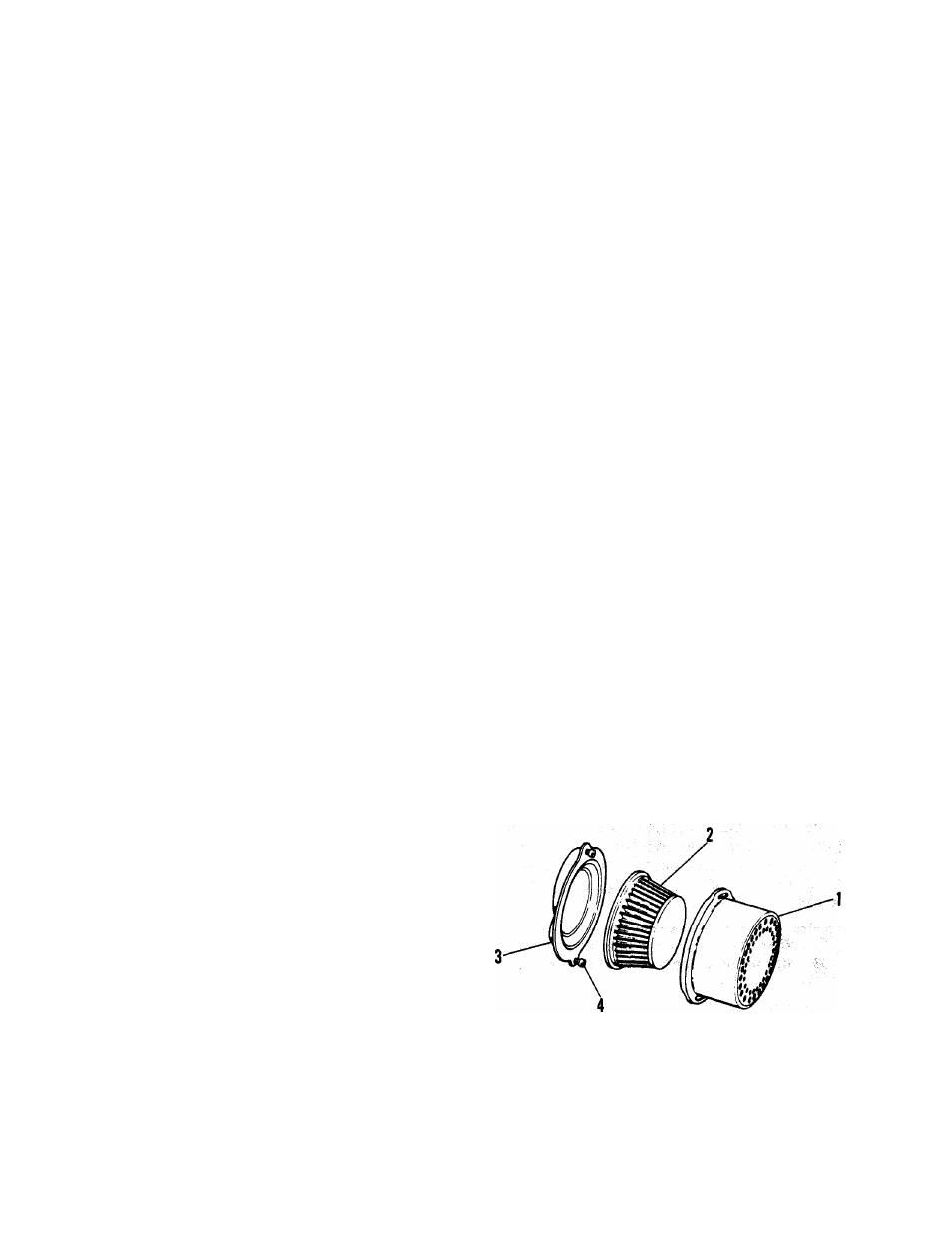

1. Cover

2. Filter

3. Base

4. Cover Retaining Screws

Figure 6: Air Cieaner

12