Forward clutch bail adjustment, Checking and adjusting reverse drive belt tension, Models 634f/634b only) – Troy-Bilt TUFFY 630C User Manual

Page 20: To check reveree belt tension, Replacement belt information, Engine cleaning, Air cleaner service, Engine oil service, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A

WARNING:

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all

moving parts to come to a complete stop, disconnect spark plug wire and move wire away from

spark plug. Failure to follow these instructions can result in serious persona! injury or property

damage.

FORWARD CLUTCH

BAIL ADJUSTMENT

If the Forward Clutch Bail does not func

tion properly, first check that the forward

drive belt is adjusted properly (see Check

ing and Adjusting Forward Drive Belt Ten

sion).

If this fails to correct the problem,

contact Troy-Bilt LLC or your authorized

dealer for service advice.

CHECKING AND ADJUSTING RE

VERSE DRIVE BELT TENSION

(Models 634F/634B only)

It is important to maintain correct tension

on the reverse drive belt. A loose belt will

cause the tines and wheels to slow down -

or stop completely - even though the en

gine is running at full speed.

When checking belt tension, also checkthe

belt for cracks, cuts or frayed edges and

replace it as soon as possible.

• Check belt tension after the first two

hours of break-in operation and after every

10

operating hours.

To Check Reveree Belt Tension:

1. Stop engine, wait for all parts to stop

moving and disconnect spark plug wire.

2. Remove screw in plastic belt cover and

slide belt cover (which is attached to for

ward clutch cable) out of the way.

3. Have an assistant pull the Reverse

Clutch Control knob all the way out and

hold it in that position. Measure the length

of the cable wire between the end of the

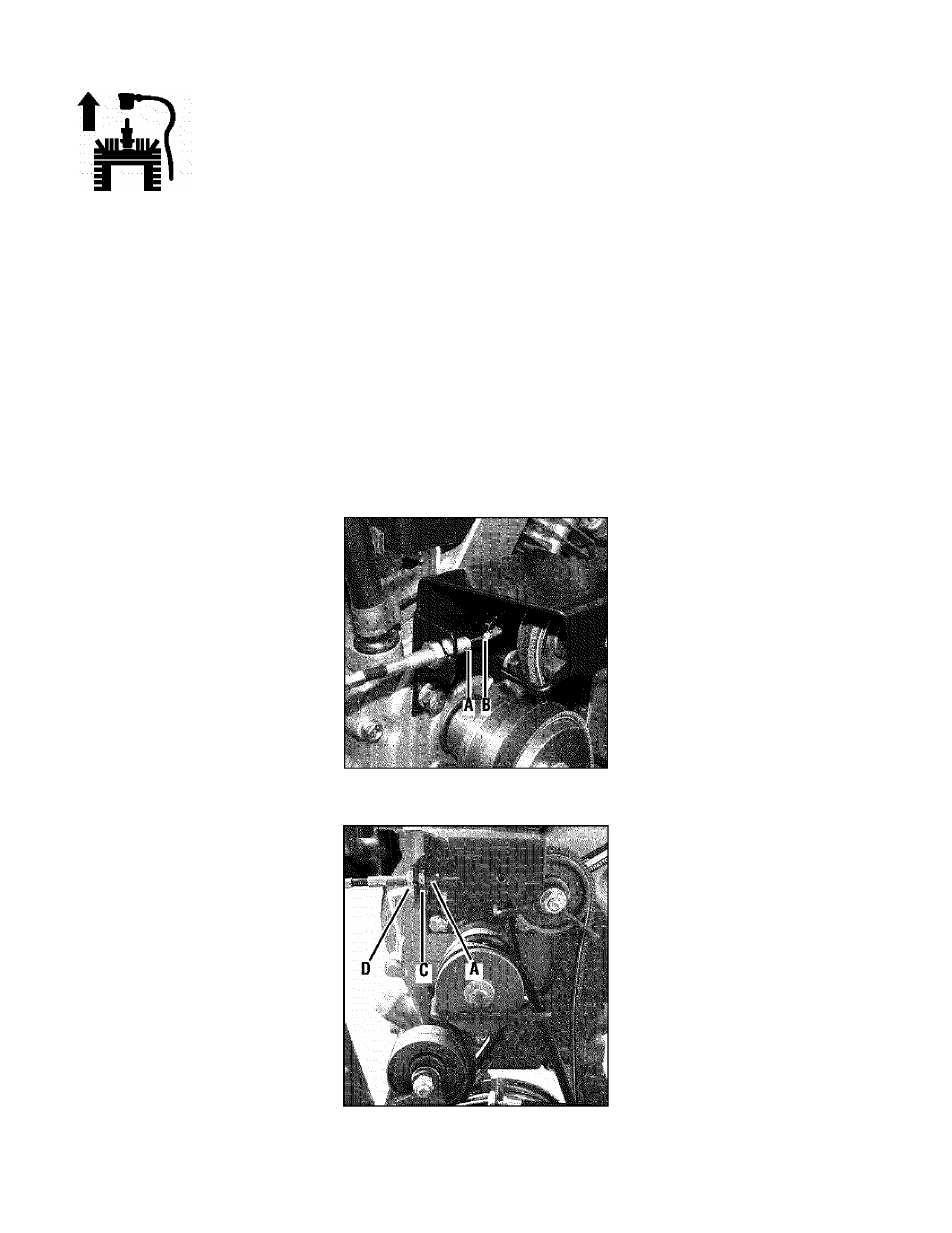

threaded cable adjuster (A, Figure 5-5) and

the end of the Z-fitting (B) to which the ca

ble wire is attached.

4.

The belt tension is ideal if the cable wire

length measures between 1/8“ to 1/4“. If it

is less than 1/8* (and if there is no reverse

action when the tiller is running), then make

the following adjustments

NOTE: If the length is more than 1/4“, no ad

justment is needed—as long as the reverse

action functions properly.

5.

Release the Reverse Clutch Control

knob.and then unthread the inner jam nut

(C, Figure 5-6) one to two turns. Pull the

threaded cable adjuster (A, Figure 5-6) to

the left until the inner jam nut (C) touches

the bracket.

6

.

Prevent the inner jam nut (C) from turn

ing and tighten the outer jam nut (D)

against the bracket. Prevent the outer jam

nut (D) from turning and tighten the inner

jam nut (C) against the bracket.

7. Measure the gap by repeating Step 3.

Readjust as needed by repeating Steps 5

and 6.

8

.

Reinstall the belt cover.

Figure 5-5: Measure cable wire length to

check for correct reverse belt tension.

Figure 5-6: Move threaded adjuster (A) to left

to increase belt tension.

Replacement Belt Information

If the drive belt needs to be replaced, see

your local authorized dealer or refer to the

Parts List for ordering information. Use

only a factory-authorized belt as an “over-

the-counter" belt may not perform satis

factorily. The procedure requires average

mechanical ability and commonly available

tools.

ENGINE CLEANING

Keeping the engine clean will help to en

sure smooth operation and prevent dam

age from overheating. Refer to the Engine

Owner’s Manual for engine cleaning ser

vice intervals and instructions. Be sure

that the muffler is cool before servicing the

engine.

AIR CLEANER SERVICE

The air cleaner filters dirt and dust out of

the air before it enters the carburetor. Op

erating the engine with a dirty, clogged air

filter can cause poor performance and

damage to the engine. Never operate the

engine without the air cleaner installed. I n-

spect and service the air cleaner more of

ten if operating in very dusty or dirty

conditions. Refer to the engine Owner’s

Manual for air cleaner service intervals and

instructions.

ENGINE OIL SERVICE

Checkthe engine oil level before each use

and after every five hours of continuous

operation. Running the engine when it is

low on oil will quickly ruin the engine.

It is recommended that you change the

motor oil after every 10 hours of operation

and even sooner when operating in ex

tremely dirty or dusty conditions. Refer to

the Engine Owner's Manual for detailed

service instructions.

A. To Check the Engine Oil Level:

1. Park the tiller on a level area and shut

off the engine.

2. Level the engine (use the Depth Regu

lator Lever to adjust the engine angle).

20