Section 5: maintenance, Warning – Troy-Bilt TUFFY 630C User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SECTION 5: MAINTENANCE

A.

WARNING:

Before ::

inspecting, cleaning or servicing

themachine, shutoff engine,

wait for all moving parts to come

to a complete stop, disconnect

spark plug wire and move wire

away from spark plug. Remove

ignition key on electric start :

models.

:

^

Failure to follow these

instructions can result in serious

persona! injury or property

damage, ^ y y

MAINTENANCE SCHEDULE

PROCEDURE

NOTES

Check motor oil level : .....................

2.3 '

Clean engirie / : / : : /

2 , 7 / : L

Check drive belt tension : : :

1,4 ;

Check nuts and boits ; \

1.4 / :)

Change motor oil T ;

4.6,9

Lubricate tiller V : :

4 , : / / / ' ,

Service engine air cleaner system

7

Check gear oil level in transmission

1 , ' 5 / / ■ ■ . ,

Check tines for wear :

Check air pressure in tires :

(if unit has pneumatic tires) L

5/'

Service spark plug : - :

7

: : : : / / ' ■ ■ •

NOTES

.........

1

- Check after first 2 hours of break-in operation.

2

■■ Before each use. ■ ■ . . ' . ' . f f

3

- Every 5 operating hours.

Every 10 operating hours.

5

7

'

5

9-

Every 30 operating hours.

Change more frequently in dusty conditions.

See Engine Owner's Manual for service

:

recommedations.

.................. : :

Whichever time interval occurs first.

Change after first 2 hours of break-in

TILLER LUBRICATION

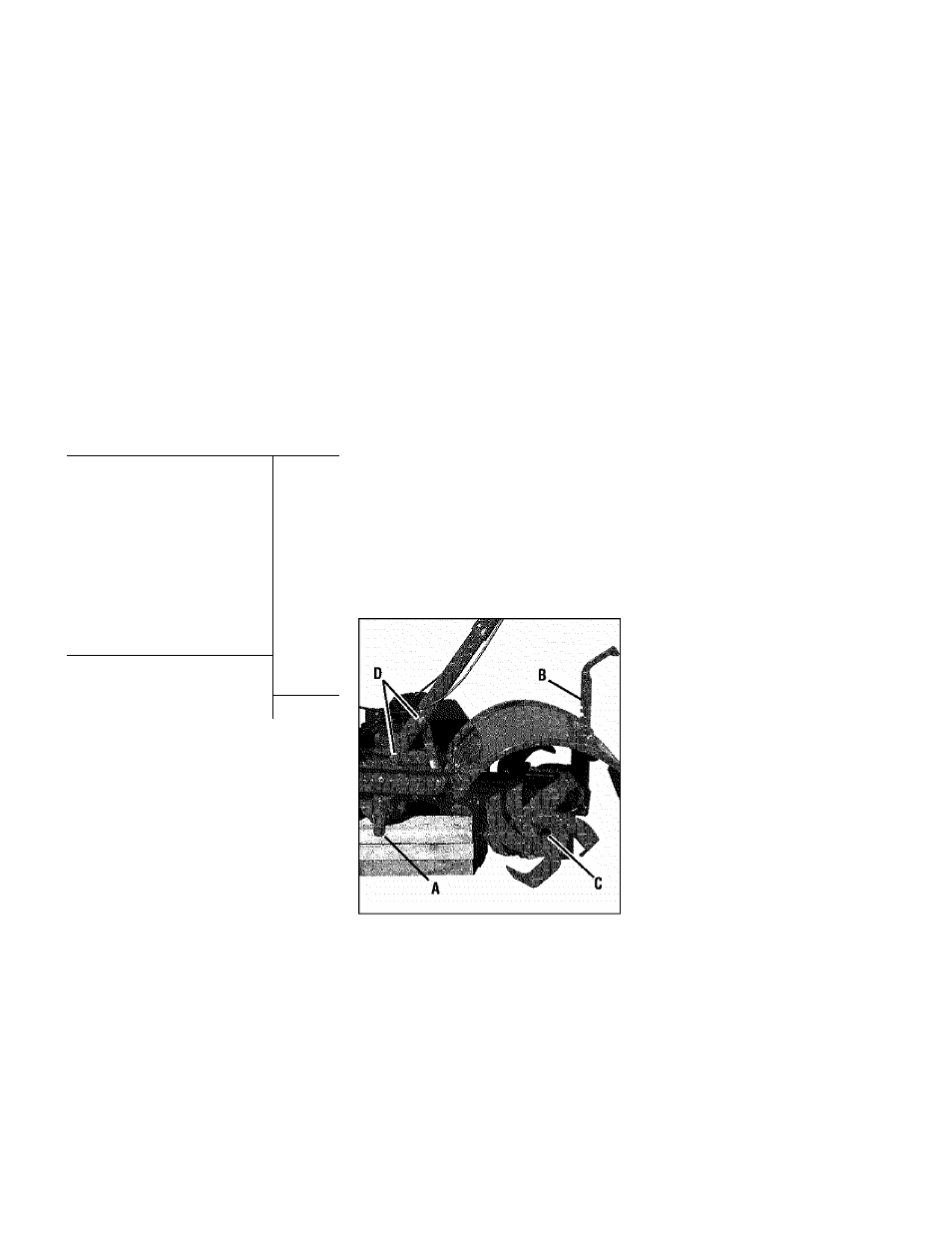

After every 10 operating hours, oil or

grease the lubrication points shown in

Figure 5-1 and described below. :

Use clean lubricating oil (#30 weight motor

oil is suitable) and clean general purpose

grease (grease containing a metal lubricant

is preferred, If available). y ::

• Remove the wheels, clean the wheel shaft

(A, Fig. 5-1) and apply a thin coating of :

grease to the wheel shaft : : : : : :

• Grease the back, front and sides of the

depth regulaior lever (B, Fig. 5-1).

: ::: :

• Remove the tines and clean the tine shaft

(C, Fig. 5-1). Use a file or sandpaper to

gently remove any rust, burrs or rough '

spots (especially around holes in shaft).

Apply grease to ends of shaft before install

ing tines.

• Oi! the threads on the handlebar height

adjustment screws and the handlebar

attaching screws (D, Fig. 5-1). : : : : : : : : : : : : : :

Figure 5‘1

CHECK FOR OIL LEAKS

Before each use, check the tiller for signs of

an oil leak — usually a dirty, oily accumu

lation either on the unit or on the floor. :

A little seepage around a cover or an oil

seal Is usually not a cause for alarm. How

ever, if the oil drips overnight, then immO'

díate attention is needed. Ignoring an oil

leak can result in severe transmission

damafife/ ■ ■ ■ ■-

17

If a cover is leaking, check for loose :

screws. If the screws are tight, a new

gasket or oil sea! may be required. ;

If the leak is from around a shaft and oil

seal, the oil seal probably needs to be

replaced. See your authorized dealer or

contact the factory fpr service or advice.

IMPORTANT: Never operate the tiller if

the transmission is low on oil. Check

the oil level after every 30 hours of

operation and whenever there is any oil

leakage.

^

CHECK HARDWARE

Check for loose or missing hardware af

ter every 10 operating hours and tighten

or replace (as needed) before reusing

tiller/::

7

:7

:'VV:/

Be sure to check the screws underneath

the tiller hood that secure the transmis

Sion cover and the Depth Regulator Lever

to the transmission. -:

CHECK TIRE PRESSURE

(Models with pneumatic tires)

Check the air pressure In both tires. The

air pressure should be between 15 PSI

and 20 PSI (pounds per square i

Keep both tires equally inflated to help

prevent machine from pulling to one

side. ..... ..

■

.

TRANSMISSION

GEAR OIL SERVICE

Check the transmission gear oil level

after every 30 hours of operation or :

whenever you notice any oil leak. Oper

ating the tiller when the transmission is

low on oil can result in severe damage.

A. To Check the Transtnission

Gear Oil Level:

1. Check the gear oi! level when the

transmission is cool. Gear oil will

expand in warm operating temperatures

and this expansion will provide an incor

rect oi! level reading. : :

: : :

: : /

2.

With the tiller on level ground, pull the

Depth Regulator Lever all the way up.

3.

Remove the oil fill plug (A, Fig. 5-2)

from the transmission housing and look

inside the oil fill hole to locate the main

drive shaft situated below the hole.