Hydraulic trouble shooting guide – MTD 243-630-000 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

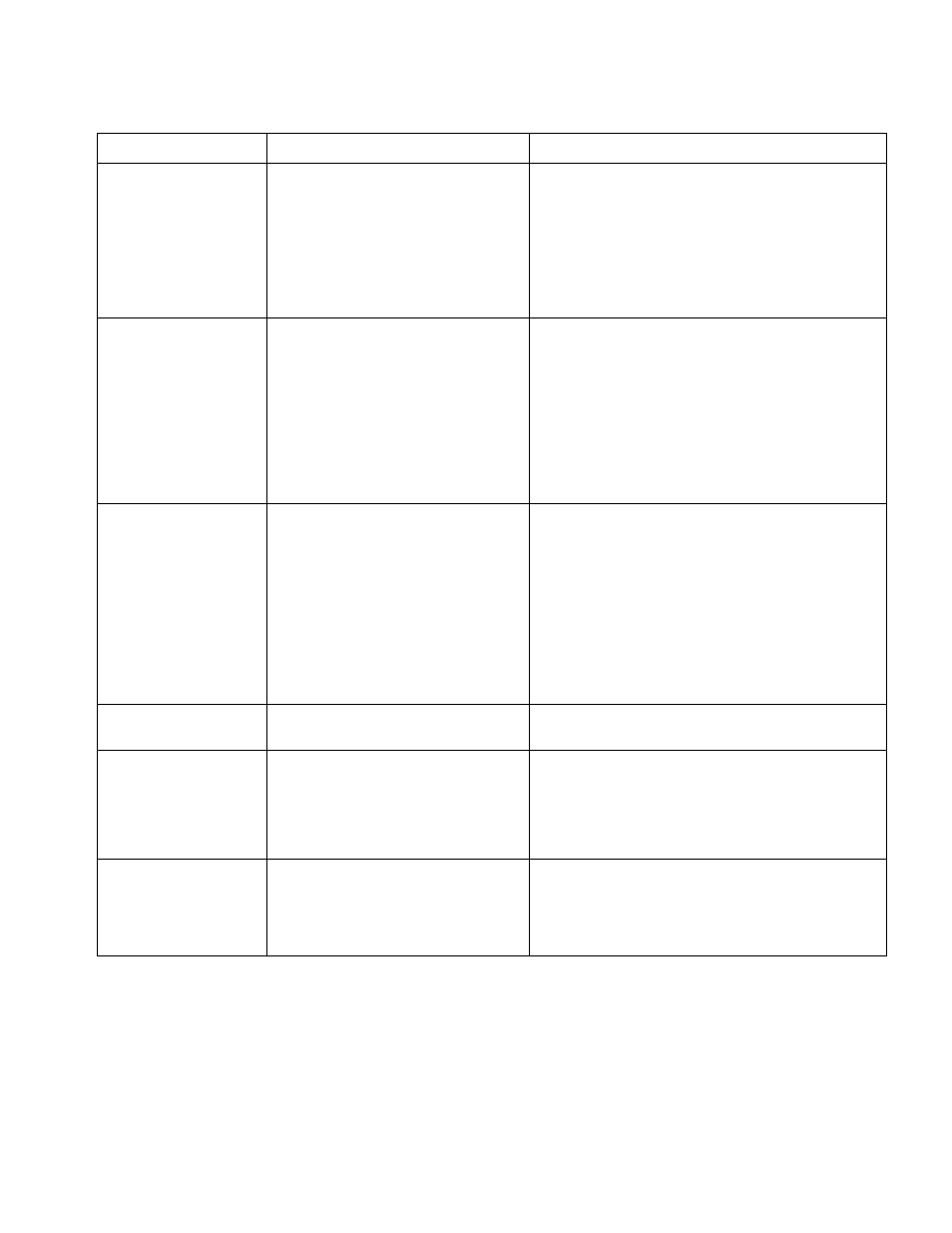

HYDRAULIC TROUBLE SHOOTING GUIDE

Probiem

Probable Cause(s)

Corrective Action

Cylinder rod will not

move

A Broken driveshaft

B Loose shaft coupling

C Gear sections damaged

D Damaged relief valve

E Hydraulic lines blocked

F Too little oil to pump

G Damaged directional valve

H Blocked directional valve

A Return pump for authorized repair

B Correct engine/pump aiignment as necessary

C Return pump for authorized repair

D Return directional valve for authorized repair

E Flush and clean hydraulic system

F Add oil to reservoir

G Return directional valve for authorized repair

H Flush and clean hydraulic system; return

directional valve for authorized repair

Slow cylinder shaft

speed while

extending and

retracting

A Gear sections damaged

B Excessive pump inlet vacuum

C Slow engine speed

D Damaged relief valve

E Too little oil to pump

F Air in oil

G Directional valve leaking internally

H Internally damaged cylinder

A Return pump for authorized repair

B Make certain pump inlet hoses are clear

and unblocked—use short, large

diameter inlet hoses

C Return engine for authorized repair

D Return directional valve for authorized repair

E Add oil to reservoir

F Add oil, clean reservoir, make certain oil

return tube is below oil level

G Return directional valve for authorized repair

H Return cylinder for authorized repair

Engine runs but

wood will not split,

or wood splits too

slowiy

A Small gear section damaged

B Pump check valve leaking

C Excessive pump inlet vacuum

D Low relief valve setting

E Too little oil to pump

F Air in oil

G Directional valve leaking internaliy

H Overloaded cylinder

I Internally damaged cylinder

A Return pump for authorized repair

B Return pump for authorized repair

C Make certain pump inlet hoses are

clear and unblocked; use short, large

diameter inlet hoses

D Adjust valve while using pressure gauge*

E Add oil to reservoir

F Add oil, clean reservoir, make certain oil

return tube is below oil level

G Return directional valve for authorized repair

H Do not attempt to split wood against the grain

I Return cylinder for authorized repair

Engine stalls during

splitting

A Low horsepower/weak engine

B Overloaded cylinder

A Return

engine for authorized

repair

B Do not attempt to split wood against the grain

Engine will not turn

or stalls under low

load conditions

A Engine/pump misalignment

B Frozen or seized pump

C Low horsepower/weak engine

D Hydraulic lines blocked

E Blocked directional valve

A Correct alignment as necessary

B Return pump for authorized repair

C Return engine for authorized repair

D Flush and clean hydraulic system

E Flush and clean hydraulic system; return

directional valve for authorized repair

Leaking pump shaft

seal

A Broken driveshaft

B Engine/pump misalignment

C Gear sections damaged

D Poorly positioned shaft seal

E Plugged oil breather

A Return pump for authorized repair

B Correct alignment as necessary

C Return pump for authorized repair

D Return pump for authorized repair

E Make certain reservoir is properly vented

*Should be performed by an authorized service deaier oniy.

15