Flexible pump coupler, Tires – MTD 243-630-000 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Service air cleaner every 25 hours under normal con

ditions. Clean every few hours under extreme ly dusty

conditions. Poor engine performance and looding

usually indicates that the air cleaner should be ser

viced. To service the air cleaner refer to the i eparate

engine manual packed with your unit.

The spark plug should be cleaned and the g.ip reset

once a season. Spark plug replacement is recom

mended at the start of each season; check engine

manual for correct plug type and gap specificafon.

Clean the engine regularly with a cloth oi brush.

Keep the cooling system (blower housing area) clean

to permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.

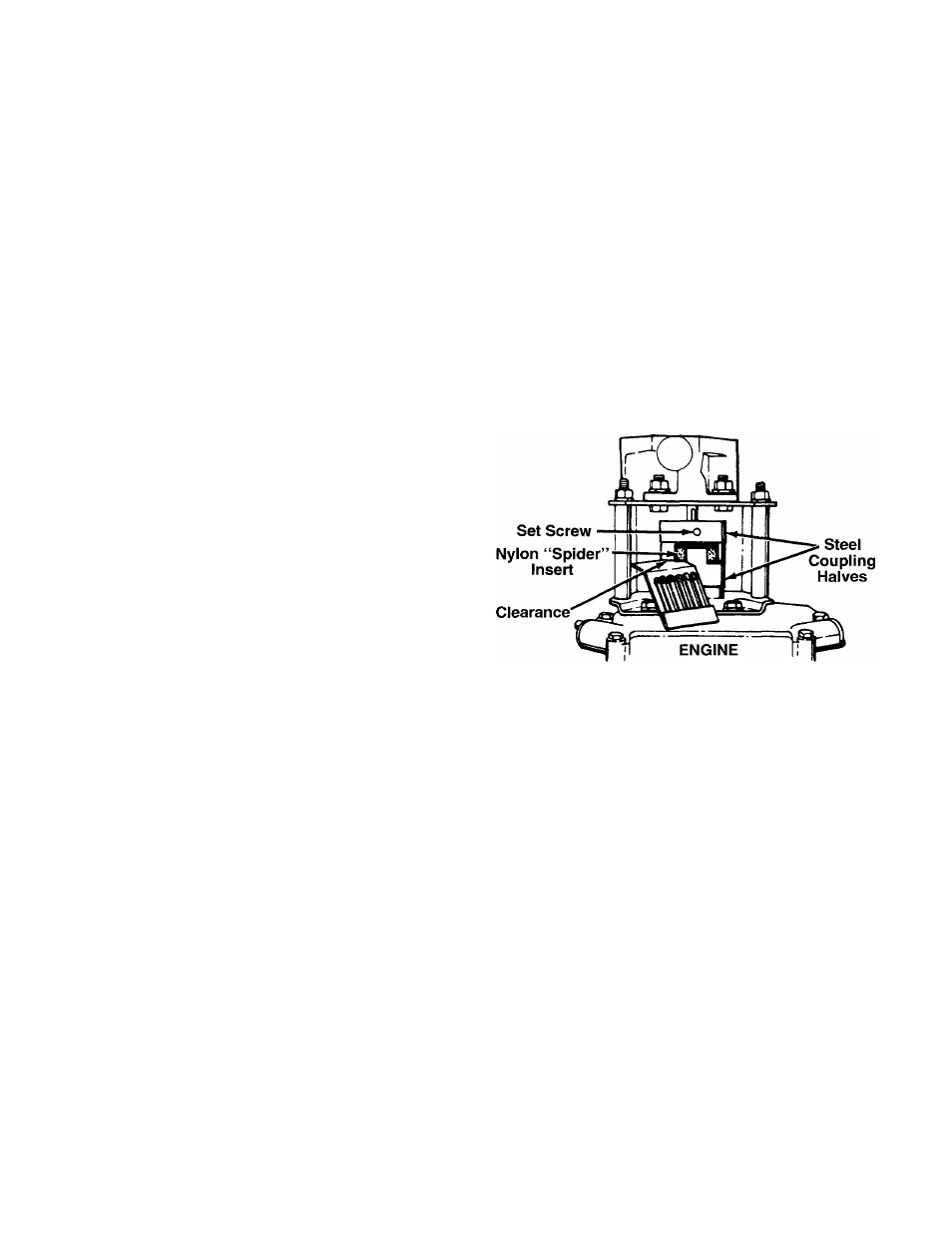

FLEXIBLE PUMP COUPLER

The flexible pump coupler is a nylon “spider’ insert,

located between the pump and engine shaft. Over a

period of time, the coupler will harden and deteriorate.

Replacement is needed if you detect vibration (>r noise

coming from the area between the engine and the

pump. If the coupler fails completely, you will experi

ence a loss of power.

For a replacement flexible pump coupler, ore er part

number 717-0891.

IMPORTANT: Never hit the pump shaft in any

manner, as any blow will cause permanert dam

age to the pump.

When replacing the flexible pump coupling, p roceed

as follows. Follow the instructions carefully as the

alignment is very critical.

1. Disconnect the spark plug wire from tha spark

plug, and secure it away from the spark plug.

Using a 1/2 inch wrench, remove three nuts and

lock washers which secure the pump to the cou

pling shield. Two nuts are at the bottom corners

and one is in the top center.

Remove the pump.

Rotate the engine by pulling starter hanc le until

engine coupling half set screw is at bottom.

Loosen set screw using 7/64 inch Allen \i/rench.

Slide coupling haif off of engine shaft.

5. Loosen set screw on pump coupling he If, and

remove coupling half.

6. Slide new engine coupling half onto the engine

shaft until the end of the shaft is flush v'ith the

inner portion of the coupling half. (There nust be

space between end of the engine support jracket

and coupling half.) Tighten set screw.

Install pump coupling half and key on pum 3 shaft.

Rotate coupling half until set screw faces down.

Do not tighten set screw.

2

.

3.

4.

8. Install nylon “spider” onto engine coupling half.

9. Align pump coupling half with nylon “spider” by

rotating engine using starter handle. Slide cou

pling half into place while guiding three mounting

bolts through holes in pump support bracket.

10. Secure with nuts and washers removed earlier.

11. Set .010 to .060 inch clearance between the

nylon “spider” and the engine coupling half by

sliding a matchbook cover between the nylon

“spider” and the engine coupling half and moving

pump coupling half as needed. Secure pump cou

pling half with set screw.

NOTE: Make certain proper clearance is obtained

before tightening set screw.

12. Reattach spark plug wire to spark plug.

PUMP

FIGURE 16.—Bottom View

TIRES

Recommended operating tire pressure is 12 to 15

p.s.i. (sidewall of tire may give tire manufacturer’s rec

ommended pressure). Maximum tire pressure under

any circumstances is 30 p.s.i. Equal tire pressure

should be maintained on all tires.

When installing a tire to the rim, be certain rim is

clean and free of rust. Lubricate both the tire and rim

generously. Never inflate to over 30 p.s.i. to seat

beads.

7.

A

WARNING: Excessive pressure (over 30

p.s.i.) when seating beads may cause

tire/rim assembly to burst with force suf

ficient to cause serious injury.

12