How your log splitter operates, The pump, The directional valve and cylinder – MTD 243-630-000 User Manual

Page 14: Operational problems

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

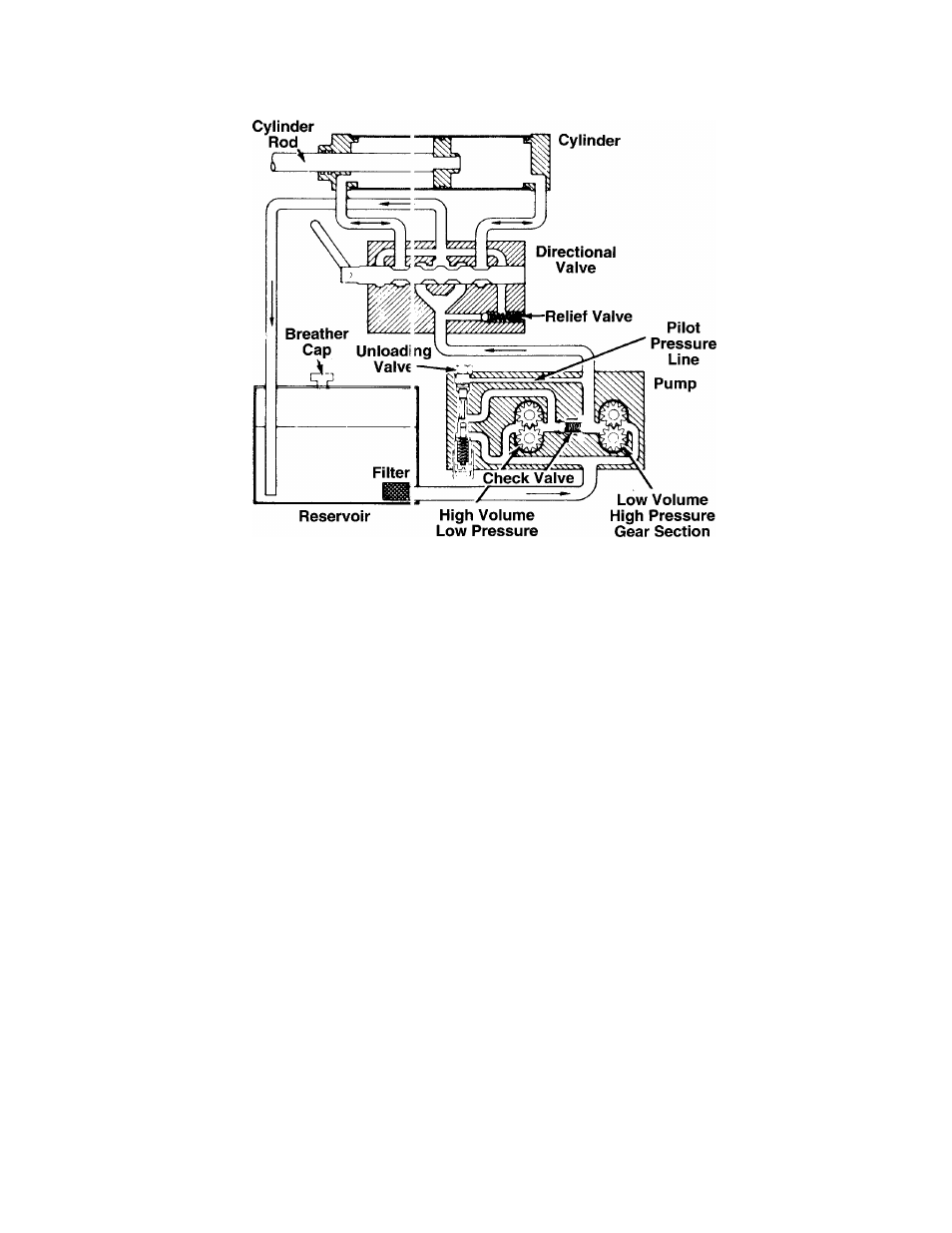

HOW YOUR LOG SPLITTER OPERATES

Gear Section

THE PUMP

A two-stage log splitter pump has one large and one

small gear section, using common inlet ant outlet

ports. Below a preset pressure (called unloading pres

sure) a check valve between the two gear ; actions

allows both flows to combine. Together, the t vo gear

sections create a large volume flow which p oduces

rapid cylinder movement under low load condilions.

Above unloading pressure, a pilot pressure line

(which simulates actual pressure at the cylindar) acti

vates the unloading valve, which causes the flow to

bypass the large gear section and return to the pump

inlet area. The small gear section is now operating

alone, and will generate the higher pressure neces

sary for the actual log splitting operation.

The original factory setting for the unloading i/alve is

designed to provide maximum flow while renaining

below engine stalling load. Note: Splitting capability

is not affected by the setting of the unloading

valve. Do not attempt to adjust or reset it /vithout

a pressure gauge (should be performer by an

authorized service dealer only).

THE DIRECTIONAL VALVE AND CYLINDER

From the pump, oil flows to a four way, three position

directional valve. At the neutral position this valve

directs the flow back to the oil reservoir, bysassing

the cylinder. When the directional valve is c irecting

the flow to the back of the cylinder, the cylirder rod

extends quickly until it meets significant res stance.

Upon reaching unloading pressure, movemert of the

shaft will slow but will continue forward. If the pres

sure reaches a preset maximum (called relief valve

pressure) the relief valve, located within the direction

al valve, will allow the flow to bypass the cylinder and

return to the reservoir. This can happen when the

cylinder rod meets excessive resistance, or when it

reaches the end of its stroke and can move no farther.

Note: Never operate at relief valve pressure for more

than a few seconds.

When the directional valve is directing the flow to the

front of the cylinder, the rod will retract quickly since it

is encountering no resistance. The relief valve will

momentarily bypass the flow at the end of the return

stroke but the directional valve should then automati

cally return to the neutral position, directing the flow

directly into the reservoir. This serves to protect the

pump from possible damage due to prolonged opera

tion at relief valve pressure.

Because of the potential for system damage, the relief

valve is carefully and precisely preset by the manu

facturer.

Note: The user should not attempt to adjust or change

the setting of the relief valve.

OPERATIONAL PROBLEMS

If you have trouble with your log splitter, please refer

to the Hydraulic Trouble Shooting Guide.

Note: Readjustment of valves or disassembly of

pump should be performed by an authorized ser

vice dealer only.

14