How to use your tiller – MTD 217-310-000 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HOW TO USE YOUR

TILLER

The tiller is a precision built machine designed for seed

bed preparation, cultivating, furrowing and mulching.

It is engineered to minimize the hardest work in the

vegetable or flower garden, to till the soil for planting

and cultivating, and for performing many other useful

labor saving tasks in the garden. With the proper

amount of care and maintenance, this machine will pro

vide the owner with many years of excellent service.

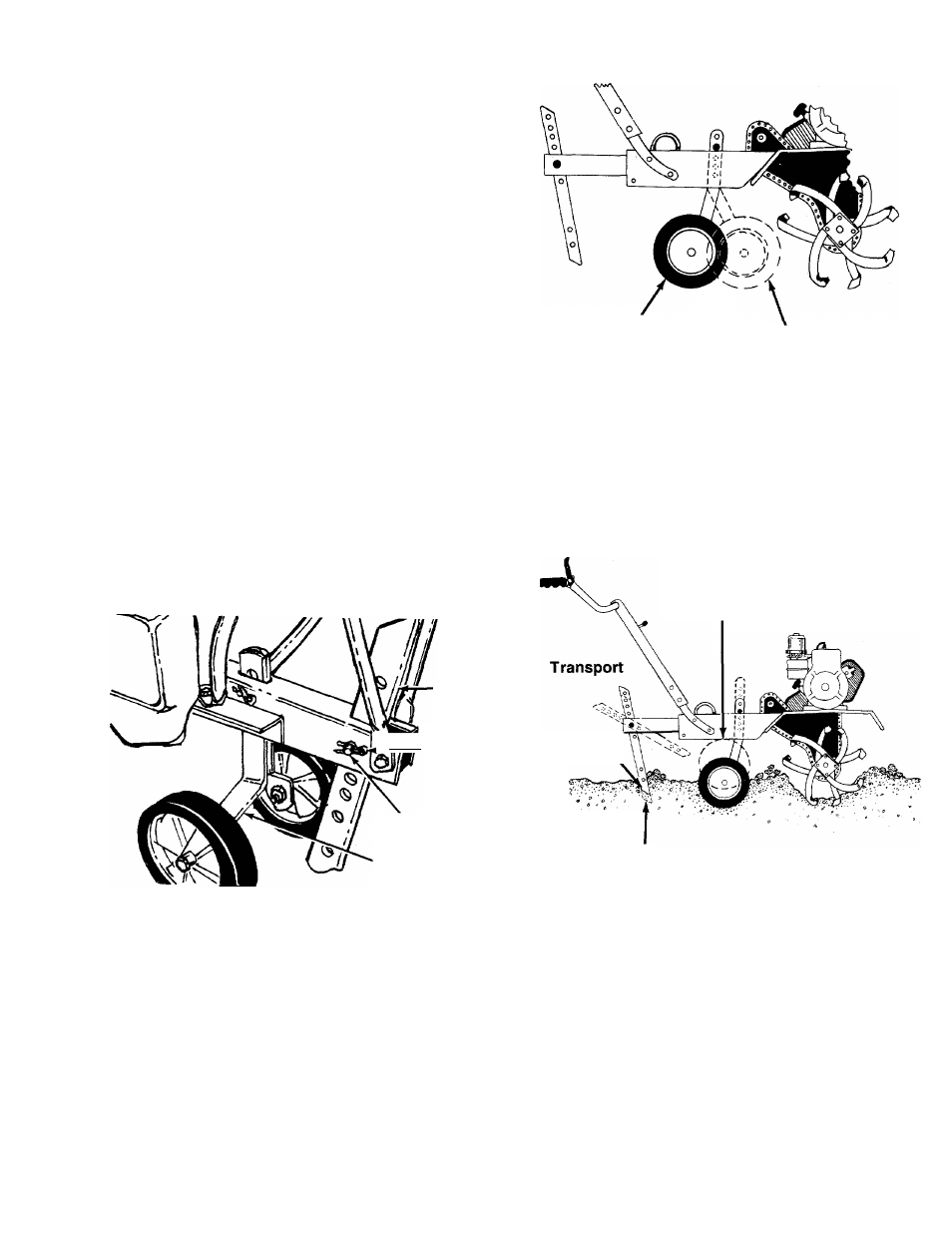

WHEEL POSITION

During digging as the tines enter the ground and the

front of the tiller lowers, the wheels must be raised to

level the unit. This is essential for proper engine opera

tion. This adjustment is made by removing the clevis

pin and hairpin cotter from wheel yoke, raising the

wheels to the desired height, and replacing the clevis

pin and hairpin cotter. See figure 22.

Wheel Yoke in

this position

for deep dig.

FIGURE 23.

Wheel Yoke in this

position for shallow

dig, cultivating and

transport.

2. Depth Bar Adjustment: The depth bar acts as a

brake for the tiller and controls the depth and

speed at which the machine will operate. See

figure 24. Remove the clevis pin and hairpin cot

ter to raise or lower depth bar.

Depth

Bar

OK» Hairpin

Cotter

Clevis

Pin

Wheei

Yoke

Wheel Setting

For Deep Digging

Shallow Dig

Fast Forward

Deep Dig Slow

Forward

FIGURE 22.

FIGURE 24.

CONTROLLING SPEED AND TILLING DEPTH:

1. Wheel Yoke Adjustment: Place wheel yoke so

that the wheels are forward (nearest point between

wheels and tines) for shallow tilling, cultivating and

transport. This will also increase the forward

speed. See figure 23. Turn yoke around (farthest

point between wheels and tines) for deep tilling.

Forward speed will decrease. See figure 23.

By increasing the depth of the depth bar, the for

ward speed of the machine is reduced, and the

working depth is increased. When the depth bar

is raised, the working depth of the machine is re

duced and the forward speed is increased. The

working depth of the machine may be predeter

mined by setting the depth bar and wheels so that

the wheels are about four inches from the ground

when the tines and depth bar are resting on the

ground. This setting will permit a working depth of

about four inches.

11