SINGER 29K73 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TO OPERATE THE MACHINE

NEEDLES

1.

Raise feeding foot A, Fig. 5 by moving lifter B

upward.

2.

Place both feet upon the treadle.

3.

Turn top of hand wheel over toward you to

start machine. (If hand wheel is fitted on front of

machine, turn top of hand wheel from left to

right to start machine.)

4.

Allow the feet to move freely with the motion

of

the

treadle.

Continue

this

motion

with

an

alternating

pressure

of

heel

and

toe

until

a

regular

easy

movement

is

acquired

and

the

hand wheel is kept in continuous rotation by use

of the feet alone.

5.

When familiar with the treadle movement, and

you

are

able

to

re-start

the

machine

without

turning the hand wheel in the wrong direction,

place a piece of material under the feeding foot.

6.

Lower feeding foot by lowering lifter and oper

ate machine until you have become accustomed

to guiding the material.

Material is moved along by the feeding foot only,

and, the direction of stitching can be changed as de

sired, by turning wings. Fig.32. To make a curved line

of

stitching,

operate

machine

slowly

and,

without

turning work, turn the revolving wings enough to pro

duce the desired curve.

Feeding foot rises between each stitch while needle

is in the material. With needle serving as pivot, ma

terial can be turned in any direction. When desired,

the feeding foot may be fixed to work in a straight

line, in any direction, by tightening the knurled screw

A, Fig. 22.

Never turn the work or alter the direction of the

feed while the foot is pressing on the material, as this

may cause missed stitches and damage the surface

of the work.

Needles for MACHINES 29K71, 29K72 and 29K73

are of Class and Variety 29 x 3 for cloth and 29 x 4

for leather. Needles 29 x 3 are made in sizes 11, 14,

16, 17, 18, 19, 21, 22, 23, 24 and 25, Needles 29 x 4

are made in sizes 9, 11, 14, 16, 18, 19, 21, 22, 23,

24 and 25.

The above needles regularly have nickel finish but

can be supplied with chromium finish if ordered.

The size of the needle to be used should be deter

mined by the size of the thread which must pass freely

through the eye of the needle. Rough or uneven thread,

or thread which passes with difficulty through the eye

of

the

needle

will

interfere

with

the

successful

use

of the machine.

Orders

for

needles

must

specify

the

Quantity

re

quired, the Size number, also the Class and Variety

numbers separated by an x.

The following is an example of an intelligible order:

"100 No. 16, 29 X 3 Needles", for cloth.

"100 No. 16, 29 X 4 Needles", for leather.

The best stitching results will be obtained by using

the needles sold by Singer Sewing Machine Company.

THREAD

Left

twist

thread

should

be

used

in

the

needle.

Either right or left twist thread can be used for the

bobbin.

1

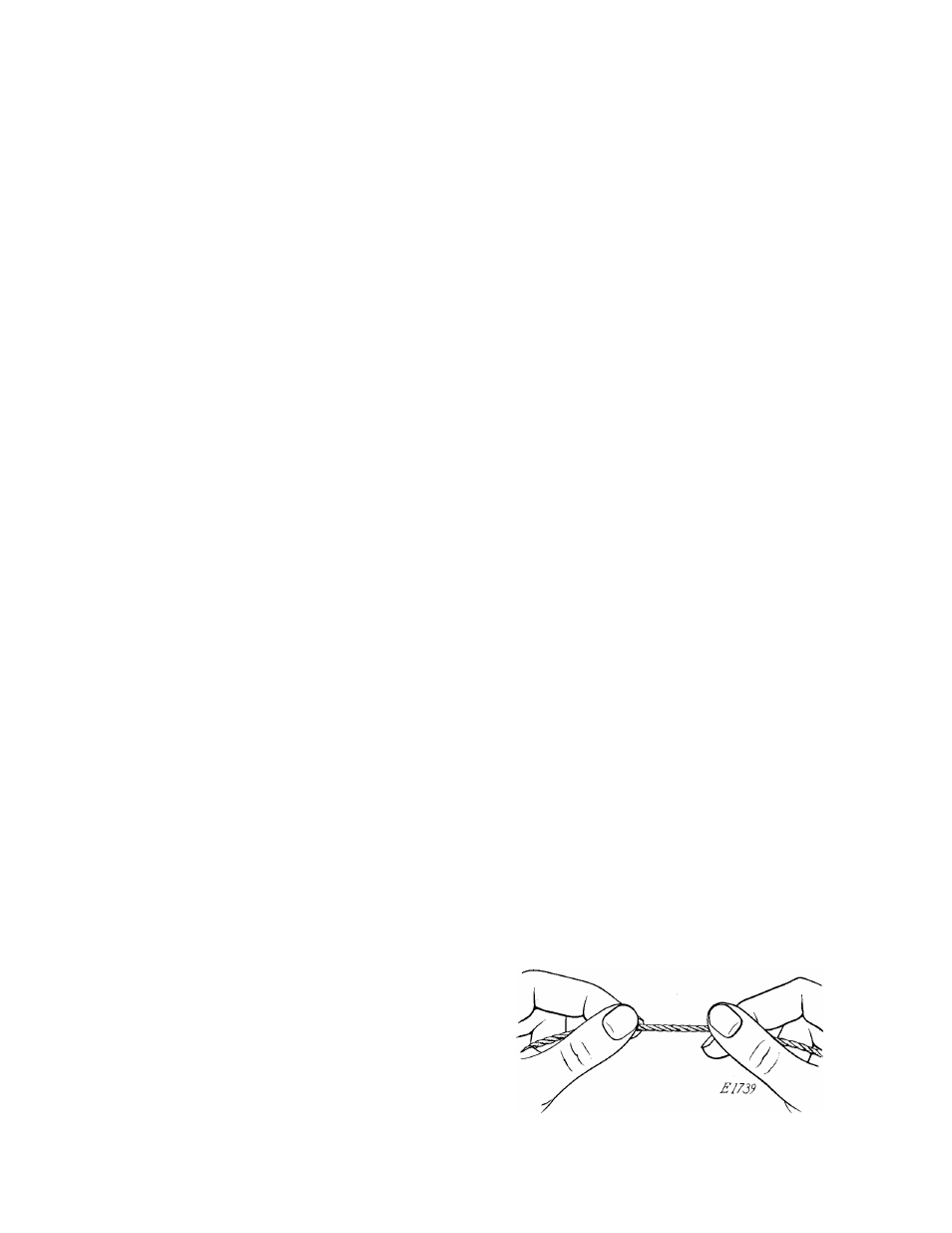

To determine the twist, hold the thread as shown.

Turn the thread over toward you between the thumb

and

forefinger

of

the

right

hand;

if

left

twist,

the

strands

will

wind

tighter.

If

right

twist,

the

strands

will unwind.

A^

C

Í

Fig. 5. Operating Machine

Fig. 6. Determining Twist of Thread