SINGER 29K73 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

15

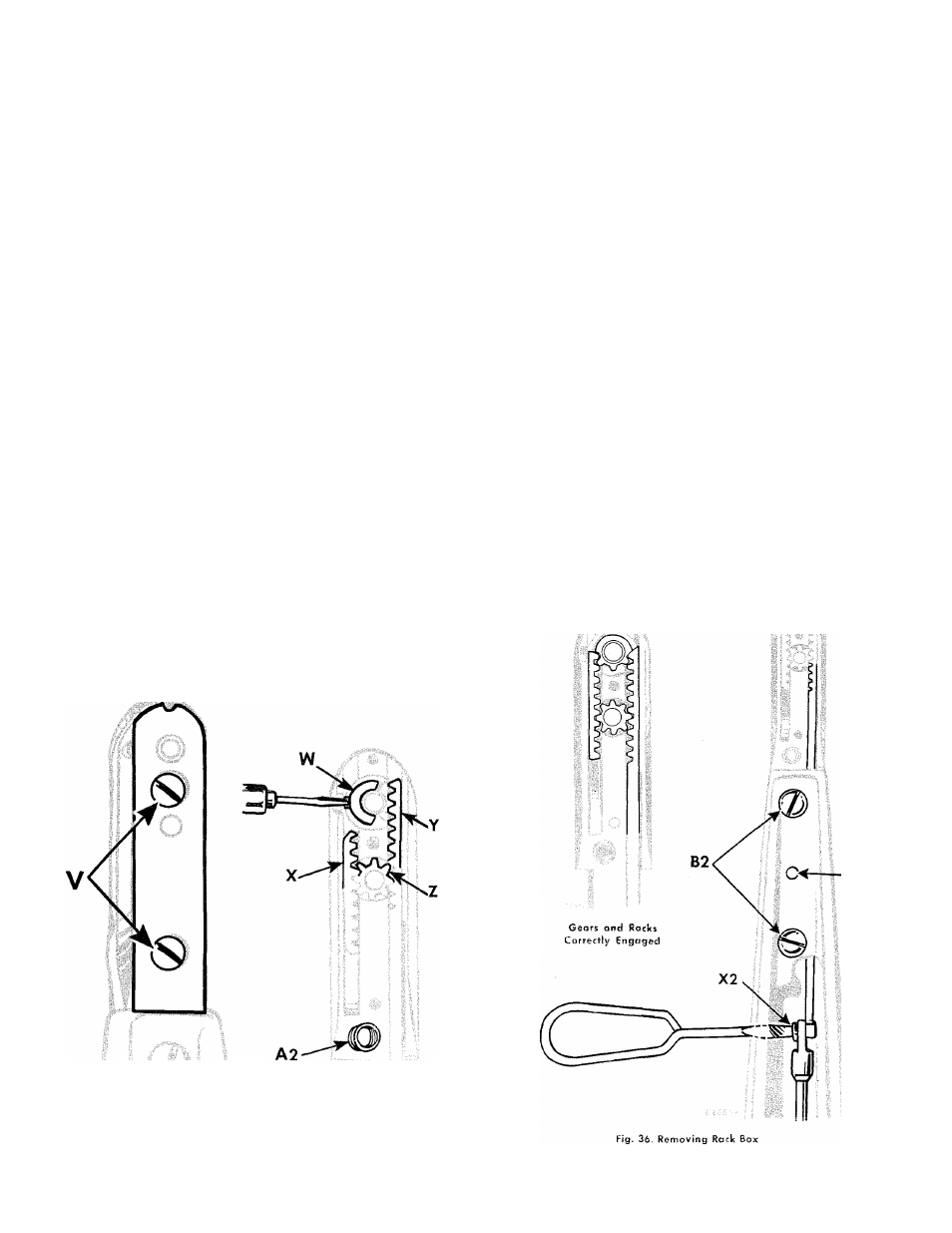

TO EXAMINE, REMOVE AND RE-ASSEMBLE THE

PARTS FROM THE RACK BOX

Remove machine from treadle stand or power bench

after taking out the four screws located at the base of

the machine. The machine should then be tilted back

upon its machine pulley end, the underside facing the

adjuster. Parts can be examined or removed from the

rack box after taking out the two screws V, Fig. 34

and removing the cover plate. The following parts are

then exposed as shown in Fig. 35: long rack Y, short

rack

X,

intermediate

pinion

Z,

shuttle

driving

pinion

W,

needle

plate

locating

pin

and

spring

A2,

all

of

which can be removed without disconnecting the rack

box from the machine.

To take out the shuttle carrier, remove the small set

screw in the shuttle driving pinion W by inserting a

small

screwdriver

through

the

groove

at

the

side

of

the rack box as shown in Fig. 35. The shuttle carrier

can then be pressed through the pinion. To remove the

long

rack

Y,

insert

a

screwdriver

through

hole

as

shown in Fig. 36 and take out the screw X2. Before

proceeding

to

withdraw

the

rack,

remove

the

pinion

Z, Fig. 35 then grip the rack and draw it straight

toward the pulley end of the machine. The short rack

X and shuttle driving pinion W can be removed with

out difficulty. When replacing any one or re-assembling

the whole of these parts, care must be taken to see

that

the

gears

and

racks

are

correctly

engaged,

as

shown in Fig. 36.

INSTRUCTIONS FOR REMOVAL OF THE

RACK BOX

If for any reason it is necessary to remove the rack

box from the machine, proceed as follows: Remove the

machine from its treadle stand or power bench. Turn

the hand wheel until the connecting rod hinge screw

X2, Fig. 36 is opposite the hole in the lower arm. Then

tilt the machine isack upon its machine pulley end, the

underside

facing

the

adjuster.

Insert

a

screwdriver

through the hole as shown in Fig. 36, and remove the

screw X2. Slightly loosen the two screws B2 by giving

them a half turn with a screwdriver. Then drive out

the taper pin C2, using a 3/16" punch and hammer,

and take out the two screws B2. The machine should

now be replaced on its, feet and the horn will then

come away if pulled in a horizontal direction.

CAUTION: Never raise the front of the horn or the

end of the long rack may be damaged.

When

re-assembling

the

box

to

the

machine,

be

sure that the taper pin C2 is driven in as far as it will

go before finally tightening the two screws B2, Fig. 36.

NOTE: Cover plate is shown removed in Fig. 36 to

illustrate how the gears and racks should be correctly

engaged.

Fig, 34. Removing

Cover Plate

Fig, 35. Removing Parts

from Rack Box