Technical gas data, Natural gas, Liquid propane (l.p.) gas – Maytag MDG120 User Manual

Page 15: Piping/connections

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NOTE: Undersized gas piping will result in

ignition problems, slow drying, increased use of

energy, and can create a safety hazard.

The dryer must be connected to the type of

heat/gas indicated on the dryer data label

affixed to the back of the dryer at the upper

right hand corner. If this Information does not

agree with the type of gas available, do not

operate the dryer. Contact the distributor who

sold the dryer.

IMPORTANT: Any burner changes or conver

sions must be made by a qualified profes

sional.

The input ratings shown on the dryer data label

are for elevations of up to 2,000 feet, unless

elevation requirements of over 2,000 feet were

specified at the time the dryer order was placed

with the factory. The adjustment or conversion

of dryers in the field for elevations over 2,000

feet are made by changing each burner orifice.

If this conversion is necessary, contact the

distributor who sold the dryer.

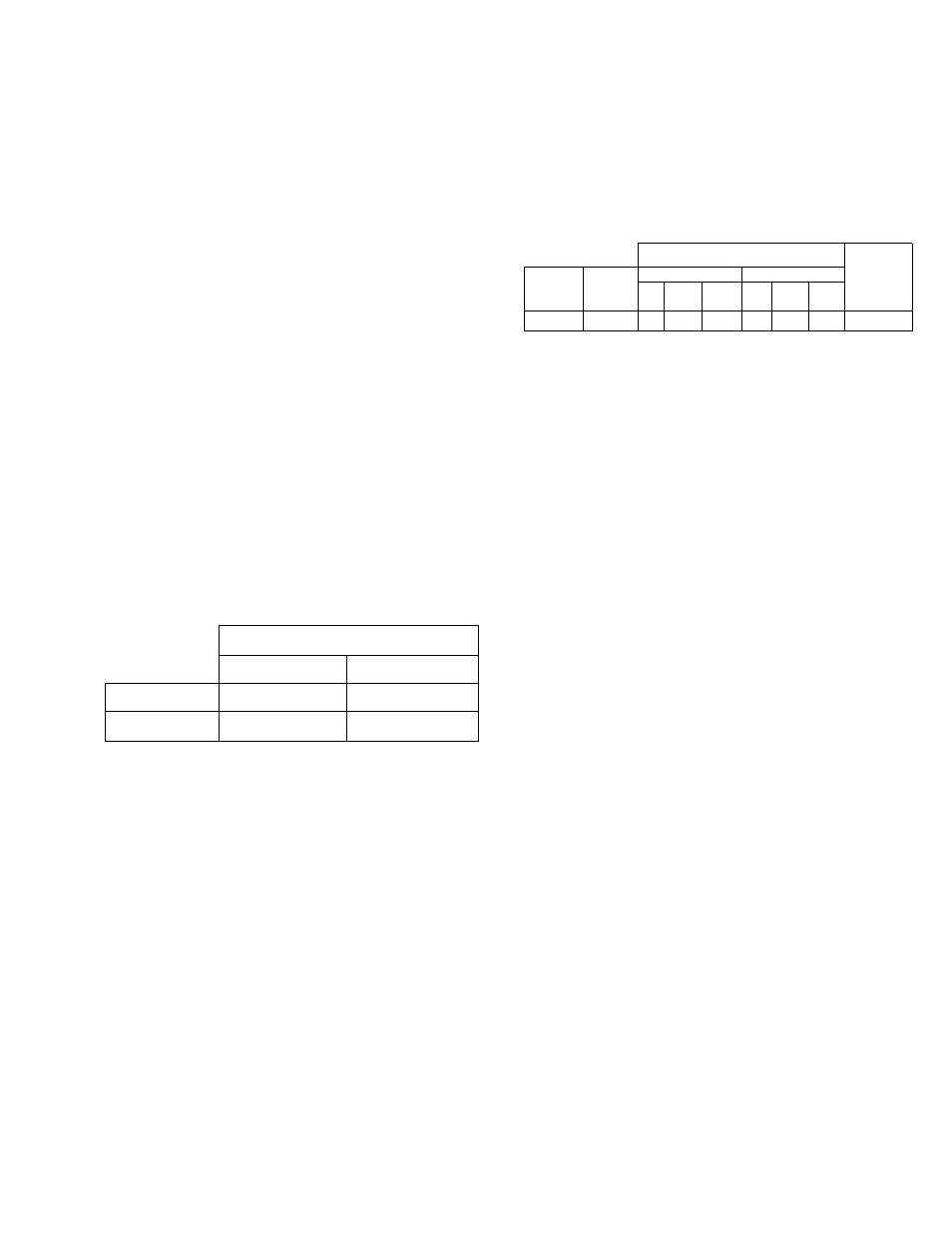

TECHNICAL GAS DATA

Gas Specifications

Type of Gas

Natural

Liquid Propane

Manifold Pressure*

3.5-4.0 Inches W.C.

10.5-11.0 inches W.C.

Inline Pressure

6.0 to 12.0 inches W.C.

11.0 Inches W.C.

* Measured at gas valve pressure tap when the gas valve Is on

GAS Connections:

Inlet connection

1-inchN.P.T.

Inlet supply size

1-inch N.P.T.

(mini

mum)

Btu/hr input (per dryer) 375,000

Natural Gas

Regulation is controlled by the dryer’s gas

valve’s Internal regulator. Incoming supply

pressure must be consistent between a mini

mum of 6.0 inches and a maximum of 12.0

inches water column pressure.

Liquid Propane (L.P.) Gas

Dryers made for use with L.P. gas have the gas

valve’s internal pressure regulator blocked

open so that the gas pressure must be regu

lated upstream of the dryer. The pressure

measured at each gas valve pressure tap must

be a consistent 11.0 inches water column.

There is no regulator or regulation provided in

an L.P. dryer. The water column pressure must

be regulated at the source (L.P. tank) or an

external regulator must be added to each

dryer.

Type of Gas

LP.

Conversion

Kit Part

Number

Model

Number

BTU

Per Hour

Rating

Natural

Liquid Propane

Qty. QM.S*

Рал.

Nurrber

Qty. □iM.a* Part

Nurtet

MDG120 375,000

3

#4

140832 3

#30 I4081S 880886

*D.M.S. (Drill Material Size) equivalents are as follows:

Natural Gas............................. #4 = .2090”

Liquid Propane Gas................#30 = .1285”

PIPING/CONNECTIONS

ALL components/materials must conform to

National Fuel Gas Code Specifications, or in

CANADA, the Canadian Installation Codes (for

General Installation and Gas Plumbing). It Is

important that gas pressure regulators meet

applicable pressure requirements and that gas

meters be rated for the total amount of all the

appliance Btu’s being supplied.

The dryer is provided with a 1-inch N.P.T. inlet

pipe connection extending out the back area of

the burner box. The minimum pipe size connec

tion (supply line) to the dryer is 1-inch N.P.T.

For ease of servicing, the gas supply line of

each dryer must have its own shut-off valve.

The size of the main gas supply line (header)

will vary depending on the distance this line

travels from the gas meter or, in the case of L.P.

gas, the supply tank, other gas-operated appli

ances on the same supply line, etc. Specific

information regarding supply line size should

be determined by the gas supplier.

NOTE: Undersized gas supply piping can

create a low or inconsistent pressure which will

result in erratic operation of the burner ignition

system.

Consistent gas pressure is essential at ALL

gas connections. It is recommended that a 1 -

inch pipe gas loop be installed in the supply line

serving a bank of dryers. An in-line pressure

regulator must be installed in the gas supply

line (header) if the (natural) gas pressure

15