SINGER 331K4 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REGULATION

BOBBIN THREAD TENSION:

For average sewing, tension on bobbin thread should

be very light.

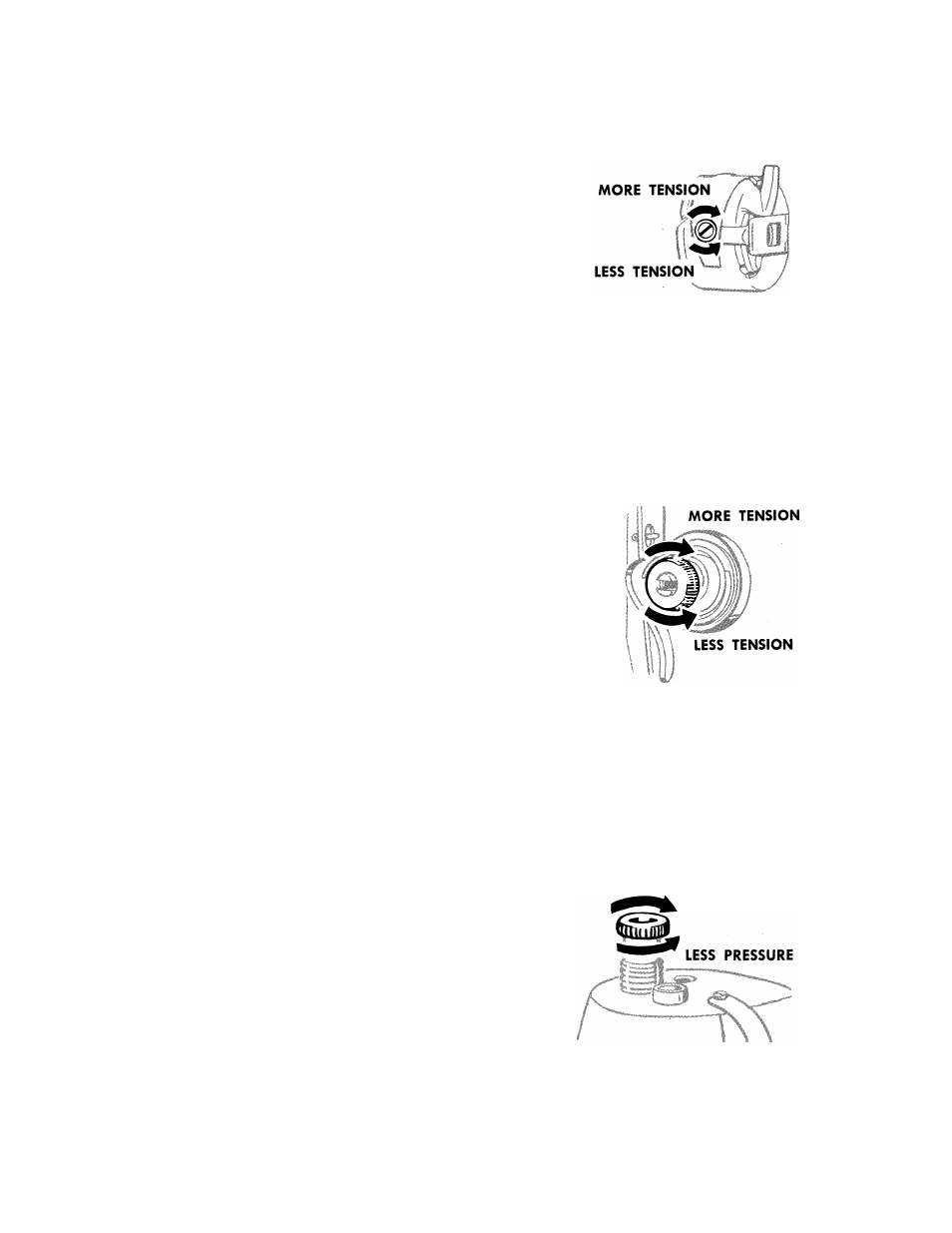

To regulate tension on bobbin thread, remove the

bobbin case and turn screw in tension spring, as in

structed in Fig. 20.

^When tension on bobbin thread has been correctly

adjusted for ordinary stitching, the required stitch

can usually be obtained thereafter to suit the work in

process by varying the tension on needle thread

only.

Fig. 20. Regulating Bobbin Thread Tension

NEEDLE THREAD TENSION:

To avoid accumulating excessive tension on needle

thread, first obtain correct tension on bobbin thread, as

instructed above.

Regulate needle thread tension only when

presser foot is down (since needle thread tension is

automatically released when presser foot is raised).

Tension on needle thread should be just enough to

set stitch correctly in material.

Having lowered presser foot, turn thumb nut at the

front of tension discs either over toward right or left, as

required. See instructions in Fig. 21.

PRESSURE OF PRESSER FOOT

ON THE MATERIAL:

Fig. 21. Regulating Needle Thread Tension

The correct presser foot pressure helps feed the

work efficiently. You can regulate the amount of pres

sure exerted by the presser foot on the material by

means of the thumb screw, as shown in Fig. 22.

The pressure on the material should be as light as

possible, while sufficient to insure correct feeding.

To increase the pressure turn the thumb screw down

ward.

To reduce the pressure turn this screw upward.

The pressure is correct when the work moves steadily

and smoothly without stalling.

MORE PRESSURE

Fig. 22. Regulating the Pressure on the Material