SINGER 331K4 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

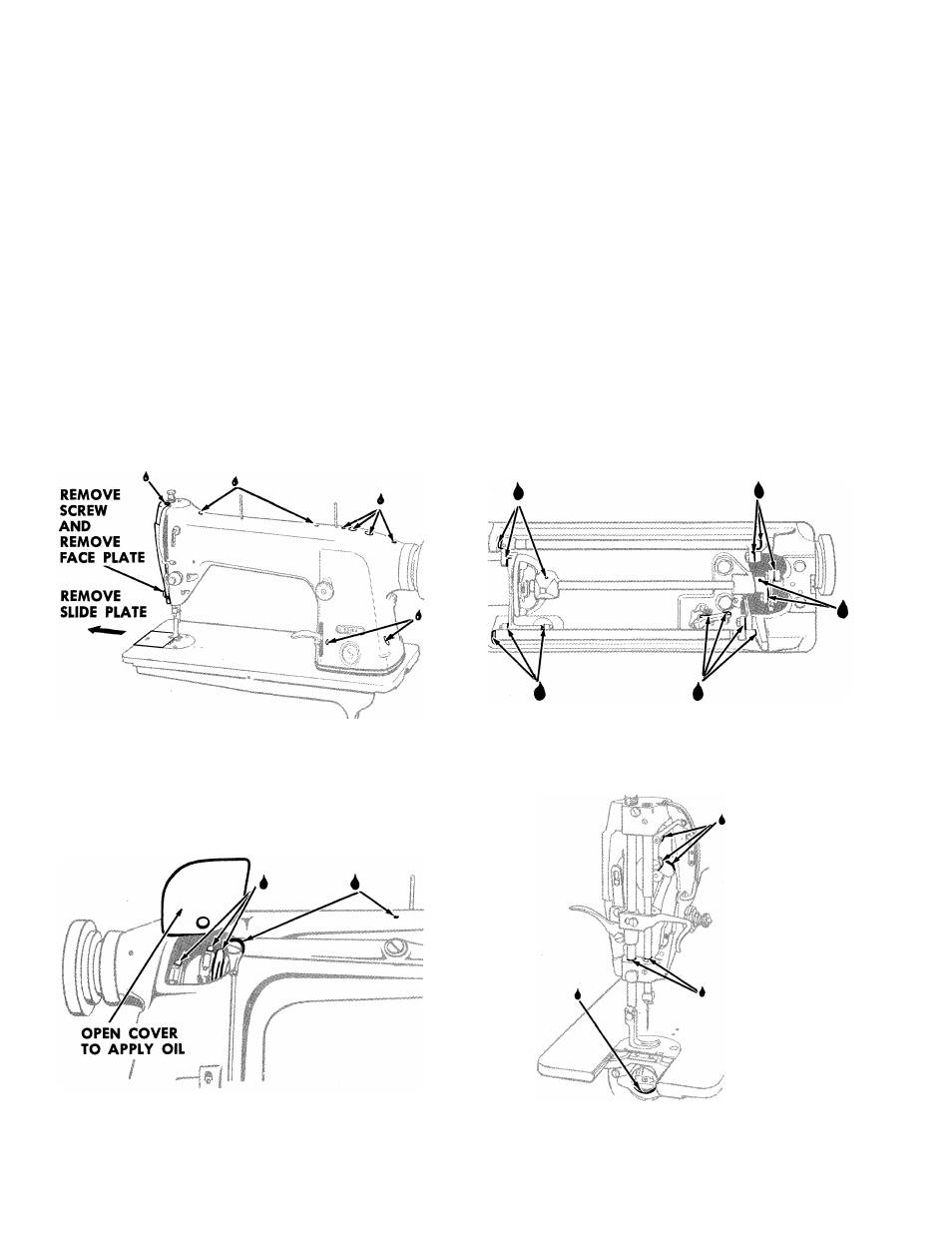

LUBRICATION AND CLEANING

Use SINGER* OIL, “TYPE B” or “TYPE D”. Use

“TYPE D” OIL when an oil is desired which will

produce minimum stain on fabrics.

A machine in continuous use should be oiled fre

quently. Frequency is dependent upon the speed at

which the machine is operated and the type of work

being done. Basically the machine needs oiling at

least twice each working day.

Before starting the machine, at the beginning of the

day and again after the midday recess, apply a few

drops of oil at each of the oiling points on the machine.

Arrows indicate oiling points in Figs. 2 through 5.

Never attempt to oil shuttle race (See Fig. 5) through

holes in throat plate.

BOBBIN WINDER LUBRICATION

Oil bobbin winder occasionally by applying a few

drops of oil to oil wick in bobbin winder frame, as

instructed in Fig. 11, page 7.

CLEANING

Clean out all lint and abrasive matter from around

the shuttle and between the feed rows on the under

side of the throat plate.

Close all covers after oiling and cleaning. Wipe off

excess oil from surfaces of machine that may come in

contact with material.

Fig. 2. Oiling Points—Front View

Fig. 4. Oiling beneath Machine Bed

Fig. 3. Oiling Points—Rear View

Fig. 5. Oiling Points behind Face Plate and in Shuttle Race