SINGER 331K4 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

13

TO SET THE NEEDLE BAR AT THE

CORRECT HEIGHT

PREPARATION:

Remove face plate, slide plate and throat plate. See

that needle is correctly set in needle bar, as instructed

on page 5.

CHECK:

When shuttle point passes centre of needle, top of

needle eye should be approximately 1/16 inch below

point of shuttle. See Fig. 29.

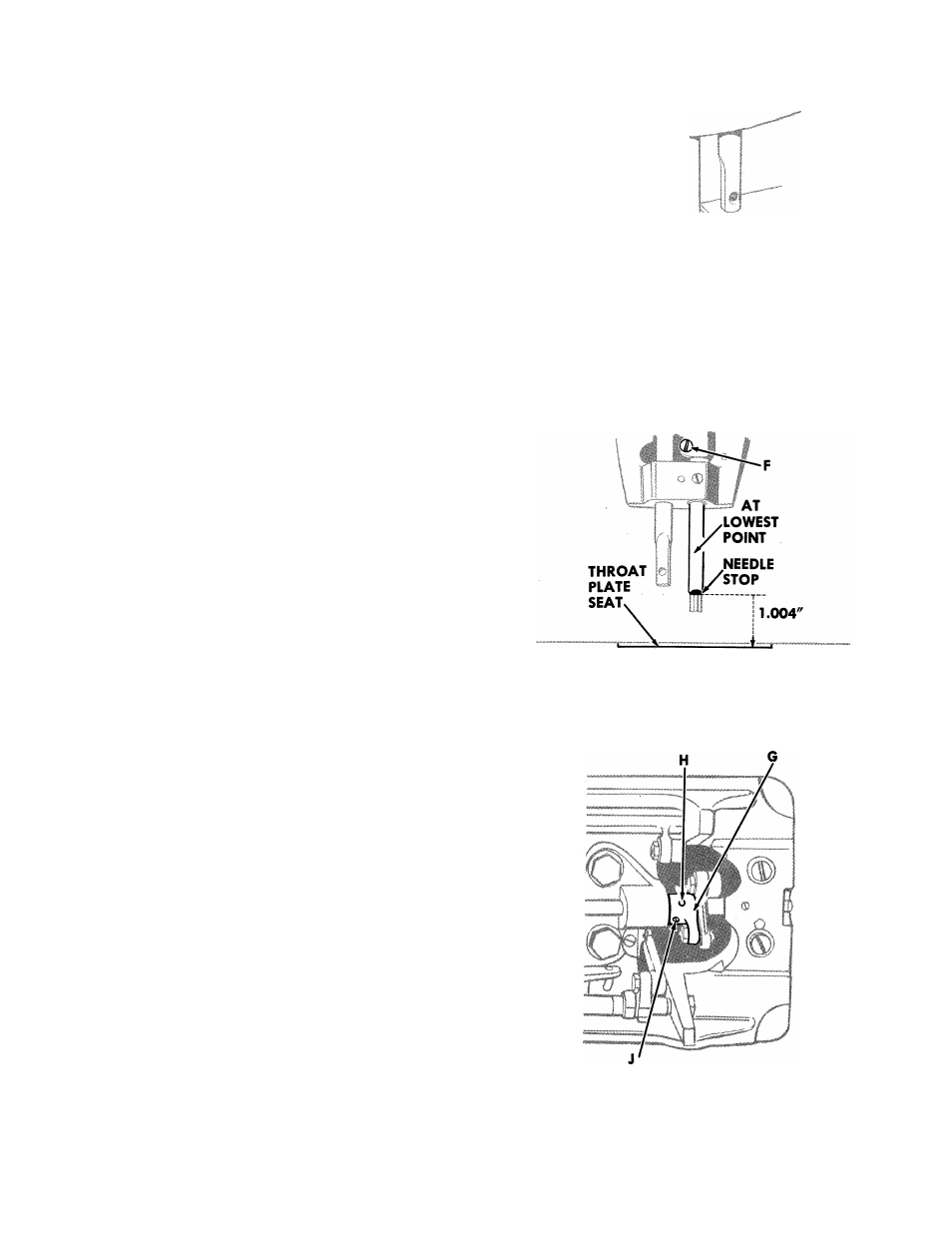

ALTERNATE CHECK:

The gauge distance from throat plate seat to needle

stop in needle bar (at lowest point) should be 1.004

inches, as indicated in Fig. 30.

SETTING:

Loosen clamping screw F, Fig. 30. Raise or lower

needle bar, as required. Then securely tighten screw F.

Replace throat plate, slide plate and face plate.

TO TIME THE SHUTTLE

EXPLANATION:

Timing of shuttle is fixed at the factory for normal

sewing conditions at a 1/10 inch loop lift.

This is accomplished by pinning the shuttle driver at

one end of the oscillating shaft and then pinning crank

G, Fig. 31 at the other end of the shaft at the specified

timing location.

TO CHECK THE TIMING:

Turn the machine pulley over toward you until needle

bar descends to lowest point and then rises approxi

mately 1/10 inch.

At this setting, for normal sewing, the point of the

shuttle should be at the centre of the needle as shown

in Fig. 29.

TO RE-SET THE TIMING:

When it becomes necessary to replace one or more

of the shuttle driving parts or to alter the timing to suit

a particular sewing condition, remove pin H, Fig. 31.

Loosen set screw J, Fig. 31.

Move point of shuttle to desired timing position and

securely tighten set screw J in crank G.

Plug pin hole in shaft and drill new hole to receive

pin in desired location.

Insert pin H.

A 4 SHUTTLE POINT

CENTER

VW

I

Fig. 29. Relationship of Shuttle Point to Needle Eye

Fig. 30. Setting Needle Bar Height

Fig. 31. Setting the Oscillating Shaft Crank

to Time of Shuttle