To remove the work, Tens i ons, To regulate the tensions – SINGER W203 User Manual

Page 8: To regulate the length of stitch, To regulate the pressure on material

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

12

To Remove the Work

Have the thread take-up lever at the highest point, raise the

presser feet, draw the work back and cut the threads close to the

goods. Lay the ends of the threads back under the presser feet.

Tens i ons

The needle and bobbin threads should be locked In the center of

the thickness of the material, thus:

Fig. 14. Perfect Stitch

If the tension on the needle threads Is too tight, or If that on

the bobbin tlireads Is too loose, the needle threads will lie straight

along the upper surface of the material, thus;

Fig, 15. Tight Needle Thread Tension

If the tension on the bobbin threads Is too tight, or If that on

the needle threads Is too loose, the bobbin threads will lie straight

along the under side of the material, thus:

Fig. 16. Loose Needle Thread Tension

To Regulate the Tensions

The tension on the needle threads Is regulated by the two thumb

nuts (N, Fig. 18) at the front of the tension discs cn the front of the

machine. To Increase the tension, turn these thumb nuts over to the

right. To decrease the tenslai, turn the thumb nuts over to the left.

The tension on the bobbin threads Is regulated by means of the

screw nearest the center of the tension spring on the outside of each

bobbin case. To Increase the tension, turn this screw over to the

right. To decrease the tension, turn this screw over to the left.

13

To Regulate the Length of Stitch

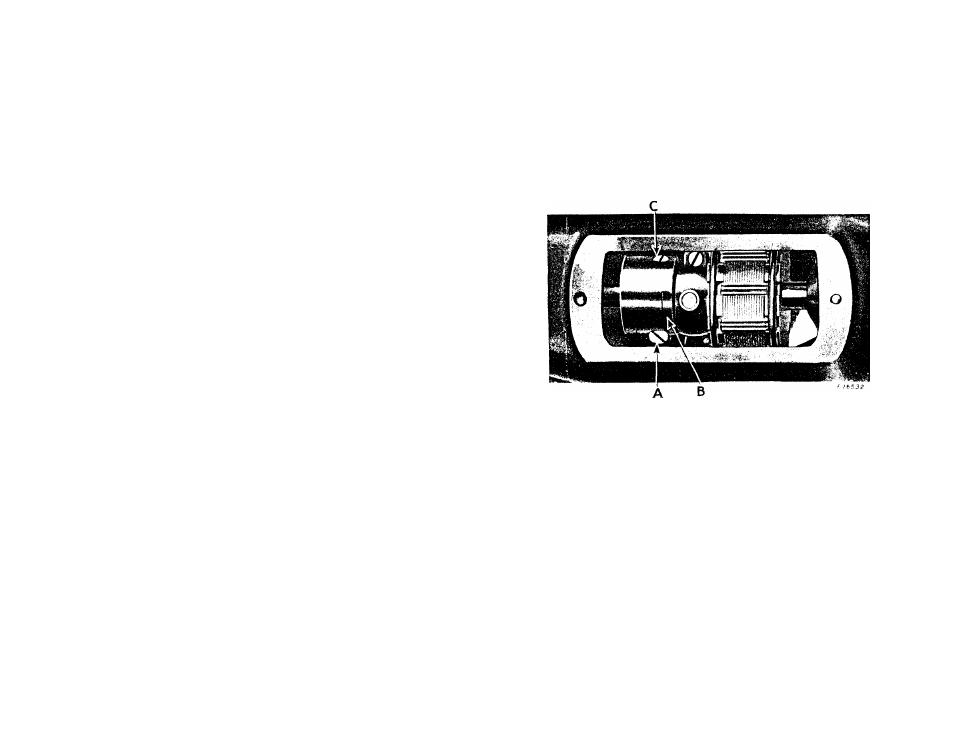

The length of stitch Is regulated by the feed eccentric (B, Fig, 17)

located on the arm shaft.

Fig, 17. Feed Eccentric. Arm Cap Removed.

To lengthen the stitch, loosen screw (C,Fig.17) turn the feed

regulating screw (A,Fig.17) over toward the left. To shorten the

stitch, turn this screw (A,Fig. 17) toward the right. When the desired

length of stitch Is obtained, securely tighten screw (C).

To Regulate the Pressure on Material

To Increase the pressure of the presser feet on the material, turn

the thumb screw (D, Flg.3), at the back of the machine, downward. To

decrease the pressure, turn this thumb screw upward.

The pressure on the material should only be sufficient to enable

the feed to move the work along evenly.