To adjust the hand-wheel shaft on machine iu&w303, Parts required for changing the gauge of a machine – SINGER W203 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

22

To Adjust the Hand-Wheel Shaft

on Machine IU&W303

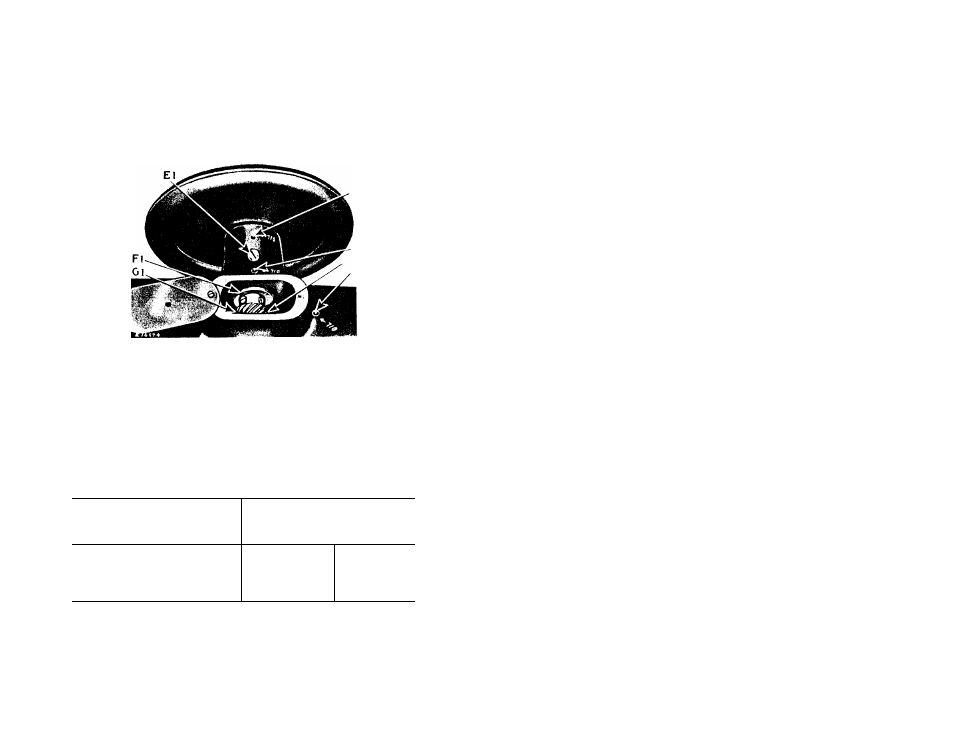

The hand-wheel shaft bushing (FI,Fig.25) Is eccentric and may be

rotated to bring the hand-wheel gear (Gl,Flg.25) Into proper engagement

Fig. 25. Rear View, Showing Adjustments and Oiling Points

at Top of Lcng-Arm Machines

with the gear on the arm shaft. Loosen the bushing set screw (El, Fig.

25) and the bushing (Fl) may then be tapped around by means of a screw

driver In holes In Inner end of bushing until there Is only a trace of

bac)tlash between the gears. Then tighten the set screw (El).

Parts Required for Changing the Gauge of a Machine

The following Hook Saddle Bearings are used for different gauges:

Gauge

Hook Saddle Bearings

(Left)

(Right)

1/4 to 1-1/8

265272

265273

1-5/32 to 2-1/16

265274

265275

2-1/8 to 2-1/2

223680

223681

When changing the gauge frcm one of these ranges to another, a new

pair of hook saddle bearings must be ordered. In addition to these,

a new feed dog, throat plate, presser foot and needle holder will be

required for each gauge.