Tensions, Work plate – SINGER 142W25 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

10

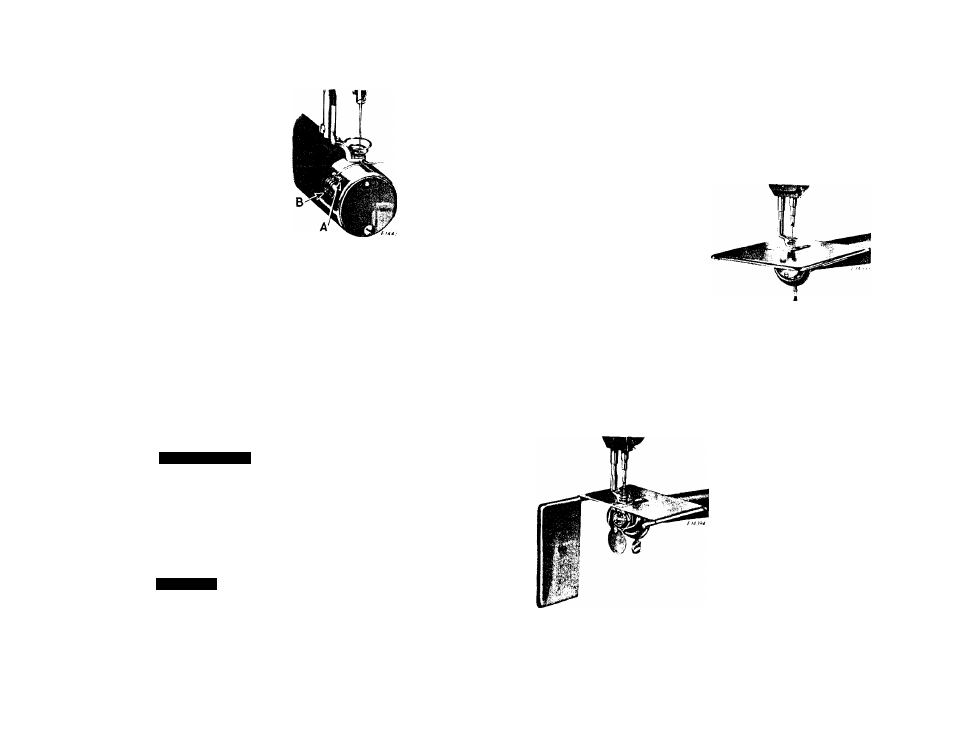

NOTE: When the machine Is equipped

with Cylinder End Cover Thread Cutter (No.

241230 complete), the bobbin thread can be

cut before removing the work from the cyl

inder by moving the darn back over the

cutter until the bobbin thread enters the

nipper spring (A,Fig.10) and Is cut by the

cutter (B). The end of the bobbin thread

Is held In the nipper spring ready for the

next darn.

Fig. 10. Thread Cutter

Tensions

The needle and bobbin threads should be locked In the center

of the thickness of the material, thus:

Fig. 11. Perfect Stitch

If the tension on the needle thread Is too tight, or If that

on the bobbin thread Is too loose, the needle thread will lie

straight along the upper surface of the material, thus:

i

Fig. 12. Tight Needle Thread Tension

If the tension on the bobbin thread Is too tight, or If that

on the needle thread Is too loose, the bobbin thread will lie

straight along the under side of tha material, thus:

Fig. 13. Loose Needle Thread Tension

To Regulate the Tensions

The tension on the under thread Is regulated by the screw

( s .

Fig.17) In the center of the tension spring on the outside of the

11

bobbin case. To Increase the tension, turn the screw

( s )

over to

the right. To decrease the tension, turn the screw over to the

left. See that there Is no lint or dirt under the tension spring.

Correctly made stitches, as shown In Fig. 11, can usually be

obtained by regulating the upper tension only, turning the ten

sion tliumb nut (C,Flg.3) Inward to tighten and outward to loosen

the tension.

Work Plate

For darning flat work, such as

table

cloths,

sheets,

towels,

aprons, lace curtains, etc.. Work

Plate complete. No. 241267 will be

found very convenient and will be

supplied when specified on order,

at additional charge.

Fig. 14. Work Plate Attached

to Machine

To Attach Work Plate

Draw toward you the cylinder end cover cap (J,Flg.6) and

slide the yoke of the work plate over the cylinder end, then

tighten the thumb screw enough to hold the work plate as shown In

Fig. 14.

To aid In quick

replacement of bobbins,

turn

back

the

left

hand portion of tlie

work plate as shown In

Fig.15.

This

can

be

accomplished

without

removing the work from

the machine.

Fig. 15. Hinged Section of

Work Plate Turned Back